Planar transmission electron microscope (TEM) sample preparation method

A sample, plane technology, applied in the field of plane TEM sample preparation, can solve the problem of loss of acquisition process, and achieve the effect of improving the success rate, reducing the manufacturing cost and saving the manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

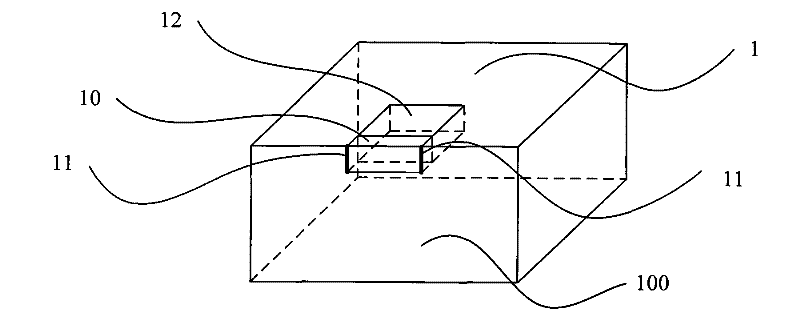

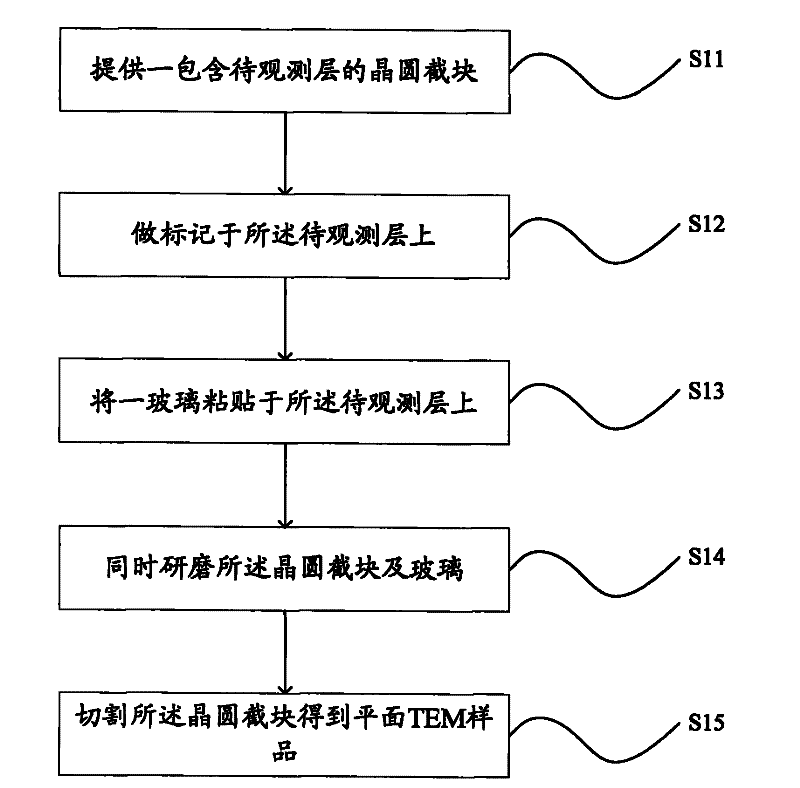

[0027] The planar TEM sample preparation method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0028] The core idea of the present invention is to provide a method for preparing a plane TEM sample. By pasting a glass on the layer to be observed of the wafer section, after cutting the wafer section to obtain a plane TEM sample, the plane The TEM sample is surrounded on all sides. Thus, when the plane TEM sample is sucked by the suction needle, even if the plane TEM sample falls off from the wafer due to the suction needle, the plane TEM sample is not sucke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com