Lithium titanate composite material and preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and composite materials, which is applied in the field of lithium titanate composite materials and its preparation, can solve problems such as difficulty in large-scale industrial application, uneven coating of aluminum phosphate, and poor cycle performance of lithium-ion batteries. The effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

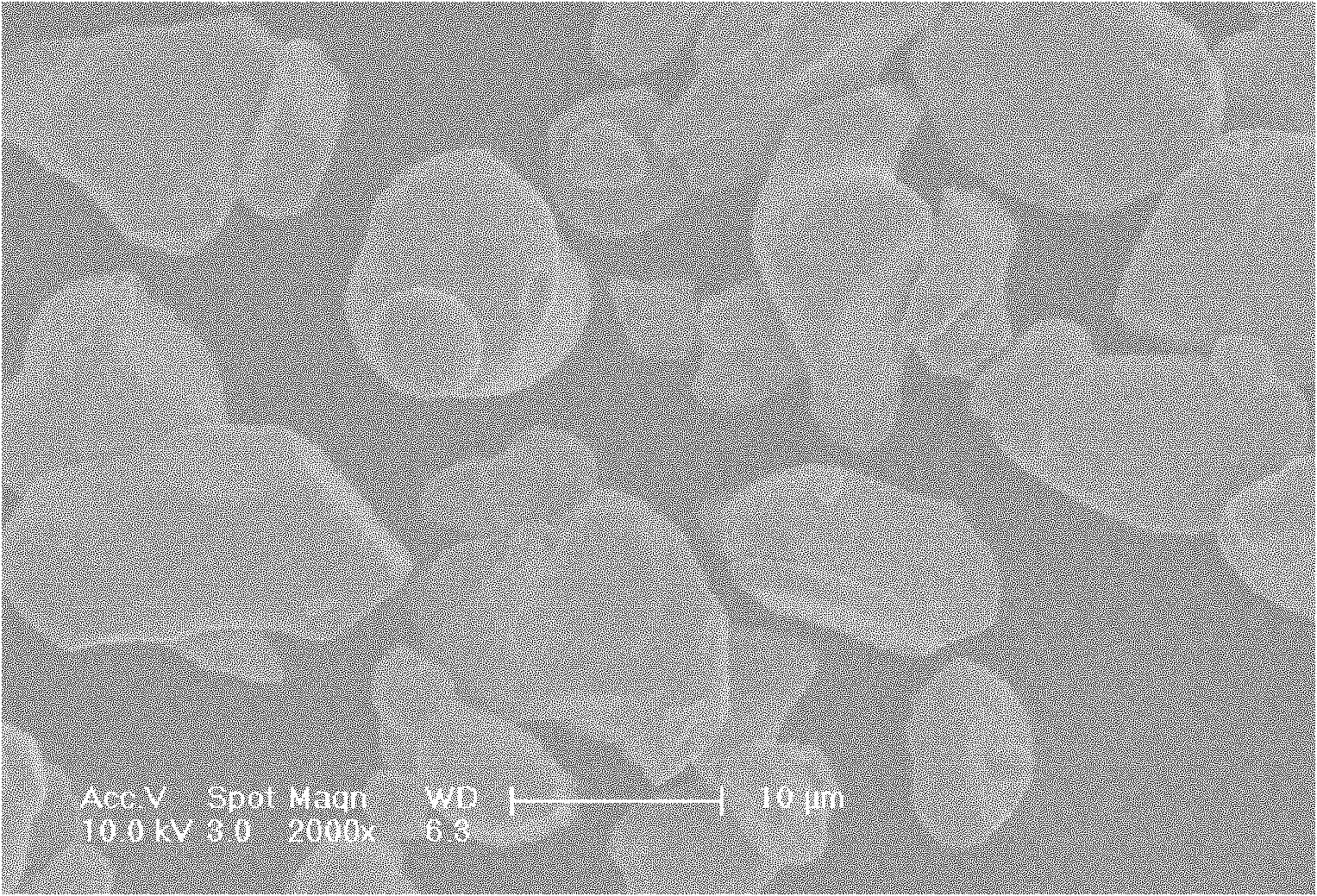

[0045] In this embodiment, the electrode active material particles are positive electrode active material lithium cobalt oxide particles, and the chemical formula is LiCoO 2 . The aluminum phosphate-lithium cobalt oxide composite material includes lithium cobalt oxide particles and an aluminum phosphate layer coated on the surface of the lithium cobalt oxide particles.

[0046] In the preparation of the aluminum phosphate-lithium cobaltate composite material, the aluminum nitrate solution is a solution formed by aluminum nitrate in ethanol. The volume of the aluminum nitrate solution is 30 ml, and the molar concentration is 0.16 mol / L. The added amount of the lithium cobalt oxide particles is 100 g. The phosphate solution is (NH 4 ) 2 HPO 4 Aqueous solution. The (NH 4 ) 2 HPO 4 With Al(NO 3 ) 3 The molar ratio is 1:1. Three samples of aluminum phosphate-lithium cobaltate composite particles were prepared under the conditions that the heat treatment temperature was 400° C., 500...

Embodiment 2

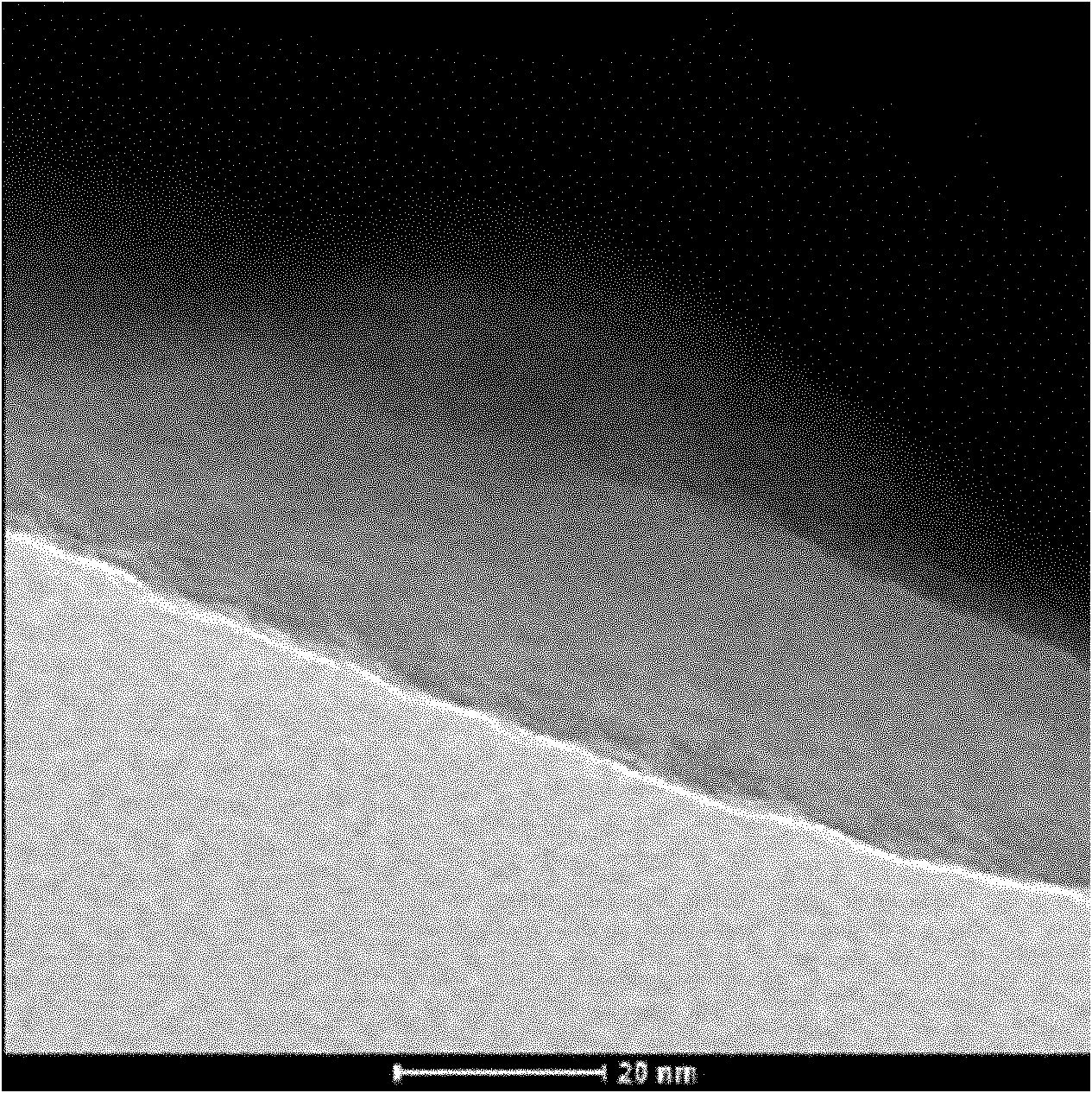

[0049] In this embodiment, the electrode active material particles are anode active material lithium titanate particles, and the chemical formula is Li 4 Ti 5 O 12 . The aluminum phosphate-lithium titanate composite material includes lithium titanate particles and an aluminum phosphate layer coated on the surface of the lithium titanate particles.

[0050] The preparation method of the aluminum phosphate-lithium nickelate composite material is the same as the preparation method of the aluminum phosphate-lithium cobaltate composite material particles of Example 1. The heat treatment temperature is selected to be 600°C, and the mass percentage of the aluminum phosphate layer to the total mass is 1.5 %, the only difference is that the material of the electrode active material particles is lithium titanate. The aluminum phosphate-lithium titanate composite material is used as the negative electrode active material, mixed with a certain proportion of conductive agent and binder and un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com