Singlechip and VC++-based step motor control device

A stepper motor and control device technology, which is applied in the direction of motor generator control, control system, electrical components, etc., can solve the problem that the stepper motor cannot be used as a DC motor and an AC motor, and can meet the accuracy requirements and improve the stepping accuracy. The effect of increasing the degree of reliability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

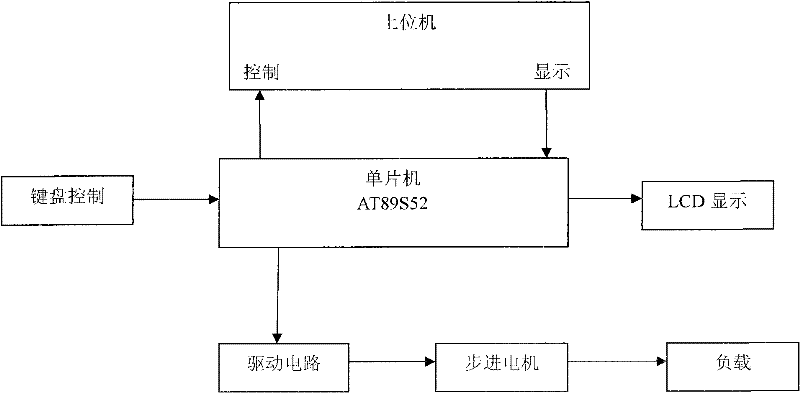

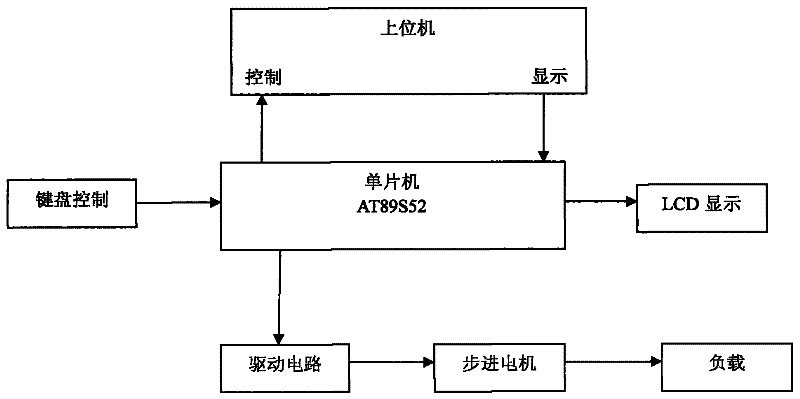

[0009] The invention includes a signal generating module, a signal distribution, and a power amplification module. The pulse signal is generated by a single-chip microcomputer AT89S52 and distributed to each phase of the stepping motor. The power amplification part is completed by a drive circuit. The stepping motor module adopts a 35BY48S03 permanent magnet stepping motor. Use the control interface of the upper computer to realize command input, and use the upper computer to display the running status in real time.

[0010] The system circuit of the single-chip microcomputer includes a clock circuit and a reset circuit. The clock circuit of the present invention adopts an internal oscillation mode, and the reset circuit function is to initialize the on-chip circuit of the single-chip microcomputer, so that the single-chip microcomputer starts to run from a certain state. The reset circuit adopts two basic Form: power-on reset, switch reset; 35BY48S03 stepping motor has four gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com