Method of manufacturing a composite structure with prefabricated reinforcement element

A technology for reinforcing components and composite structures, applied in the direction of final product manufacturing, sustainable manufacturing/processing, wind turbines consistent with the wind direction, etc., to achieve high mechanical strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

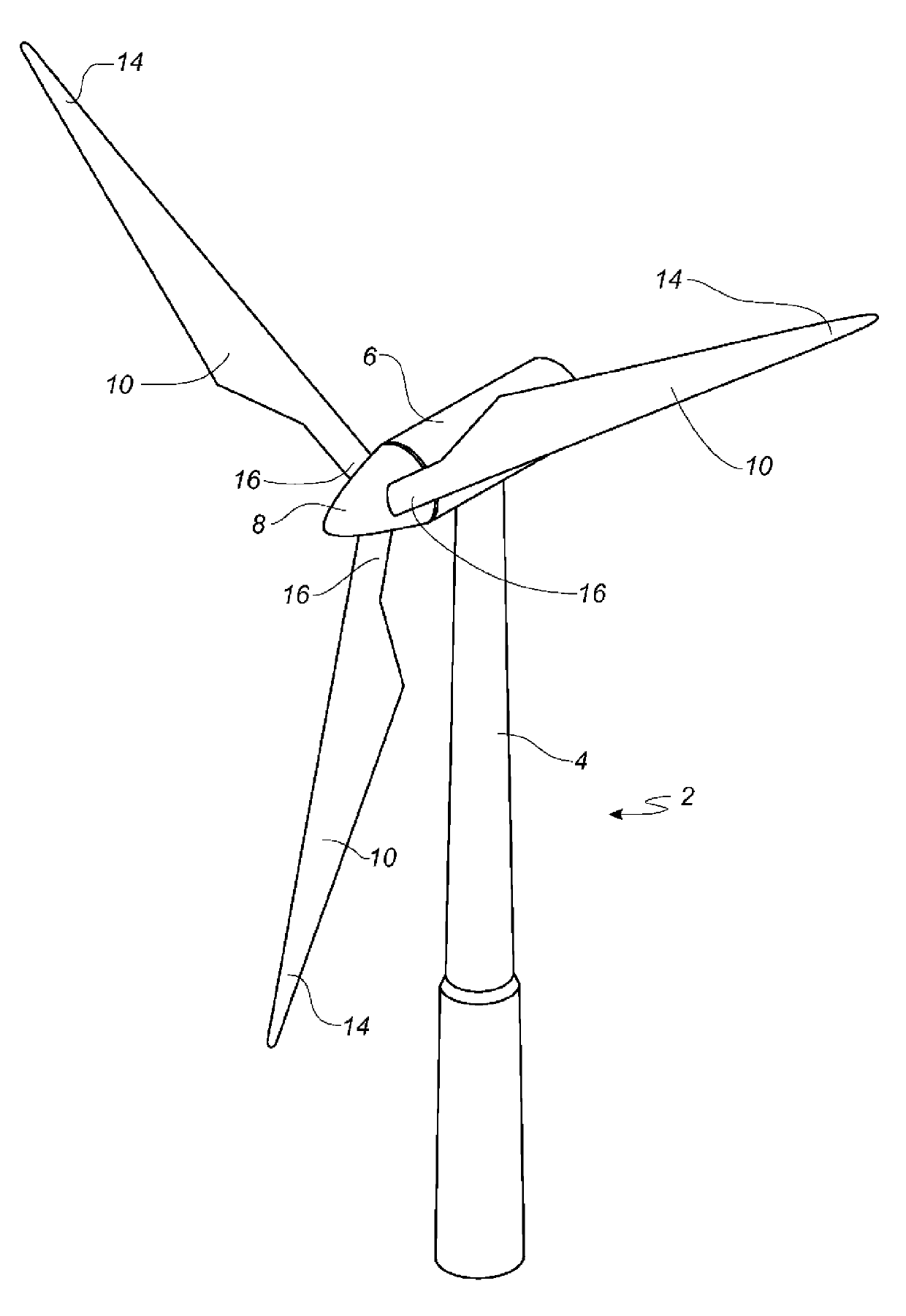

[0051] figure 1 A conventional modern upwind wind turbine according to the so-called "Danish concept" is shown with a tower 4, a nacelle 6 and a rotor with a substantially horizontal rotor shaft. The rotor comprises a hub 8 and three blades 10 extending radially from the hub 8 , each blade 10 having a blade root 16 closest to the hub and a blade tip 14 furthest from the hub 8 .

[0052] figure 2 A schematic view of a first embodiment of a wind turbine blade 10 according to the invention is shown. The wind turbine blade 10 has the shape of a conventional wind turbine blade, including a root region 30 closest to the hub, an airfoil or airfoil region 34 furthest from the hub, and a transition region between the root region 30 and the airfoil region 34 32. The blade 10 comprises a leading edge 18 facing the direction of rotation of the blade 10 when the blade is mounted on the hub and a trailing edge 20 facing in the opposite direction of the leading edge 18 .

[0053] The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com