Gearbox

A technology of transmission and receiver, applied in the direction of vehicle gearbox, gear transmission, transmission element, etc., can solve the problems of driving, fuel consumption, power loss of transmission, utilization of lubrication, etc., to achieve efficient circulation, improve reliability, restrain The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

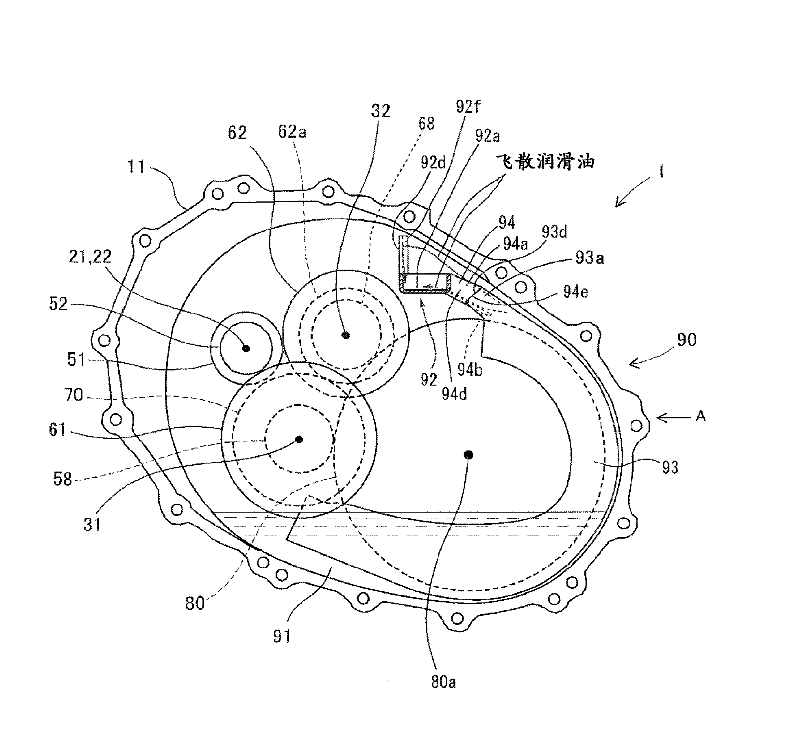

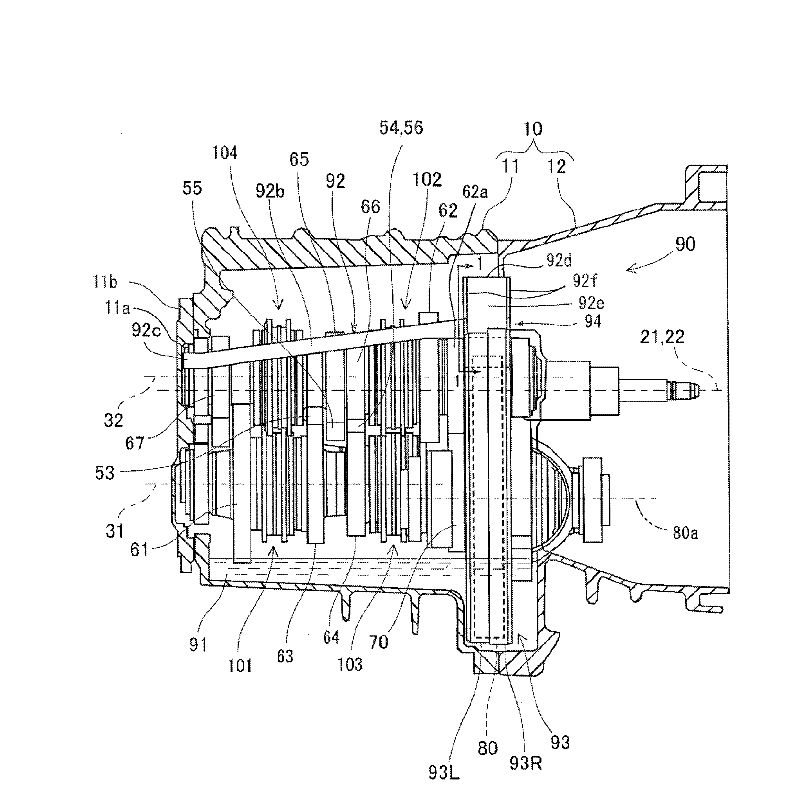

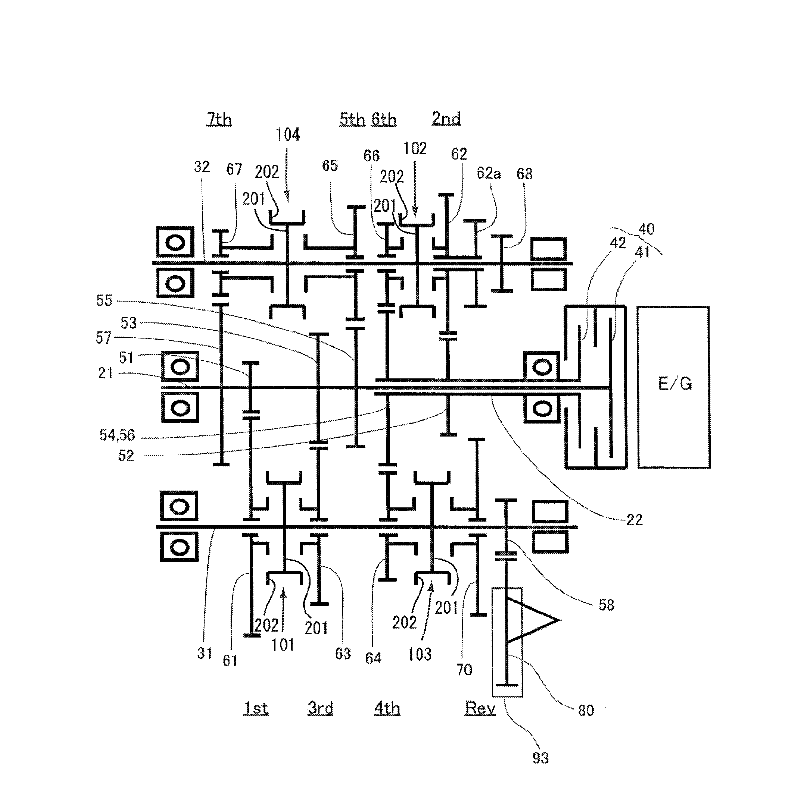

[0019] Below, refer to Figure 1 to Figure 4 The transmission 1 according to the first embodiment in which the present invention is embodied will be described. like Figure 1 to Figure 3 As shown, the transmission 1 is a dual-clutch automatic transmission, and includes a first input shaft 21 , a second input shaft 22 , a first output shaft 31 , and a second output shaft 32 as shaft bodies in the housing 10 . In addition, the housing 10 includes a dual clutch 40 , drive gears 51 to 57 for respective shift stages (corresponding to the “drive side gears” in the present invention), final reduction drive gears 58 and 68 , and driven gears 61 for respective shift stages. ~ 67 , the reverse gear 70 , the ring gear 80 (corresponding to the “large diameter gear” in the present invention), and the lubricating mechanism 90 . The final reduction drive gears 58 and 68, the driven gears 61 to 67, and the reverse gear 70 correspond to the "driven side gear" of the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com