Bi containing solid oxide fuel cell system with improved performance and reduced manufacturing costs

A solid oxide and fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problems of difficult-to-densify interconnection material manufacturing, etc., to reduce the densification temperature and reduce the thickness of the electrolyte. , the effect of reducing the kinetic resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

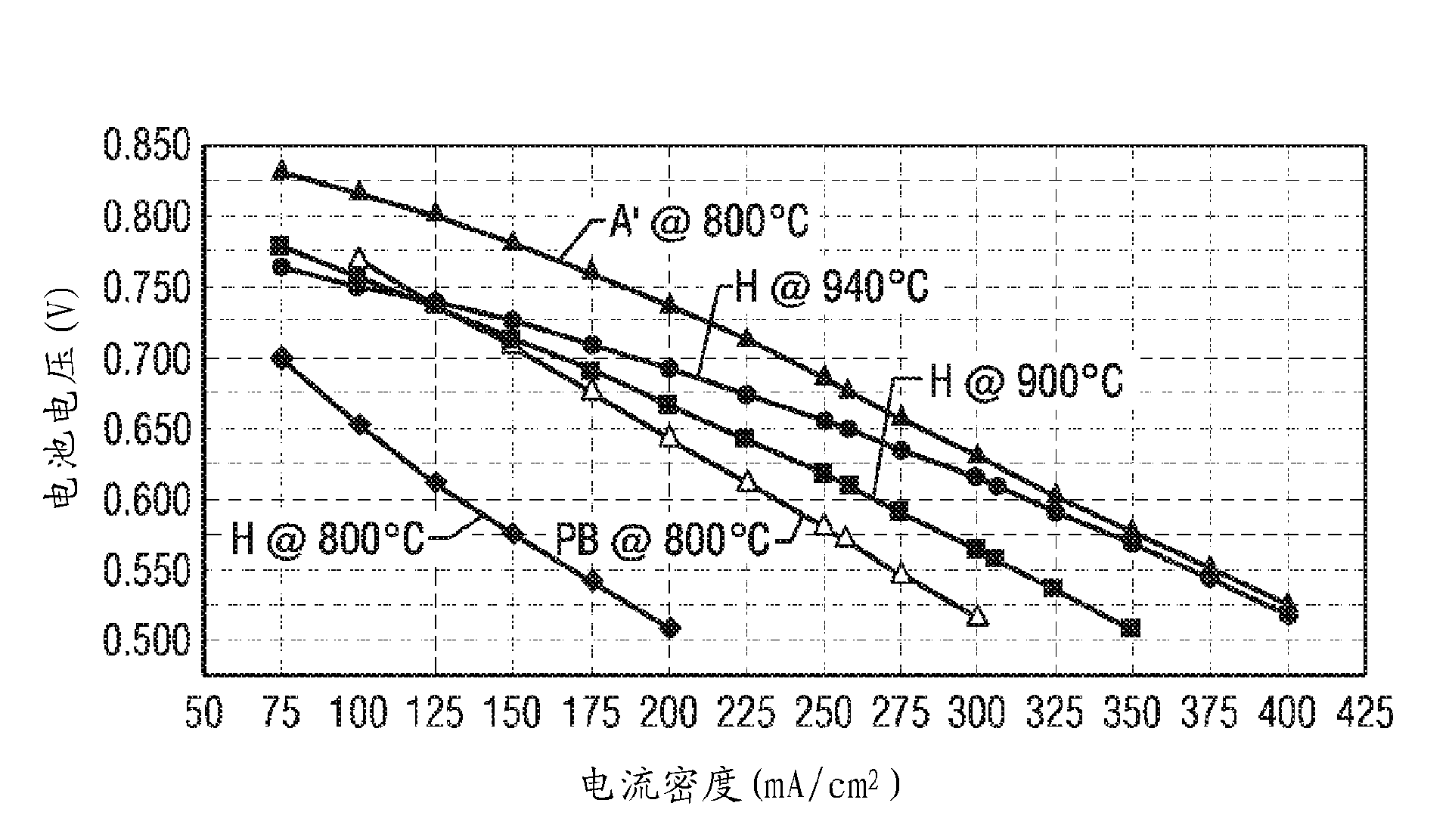

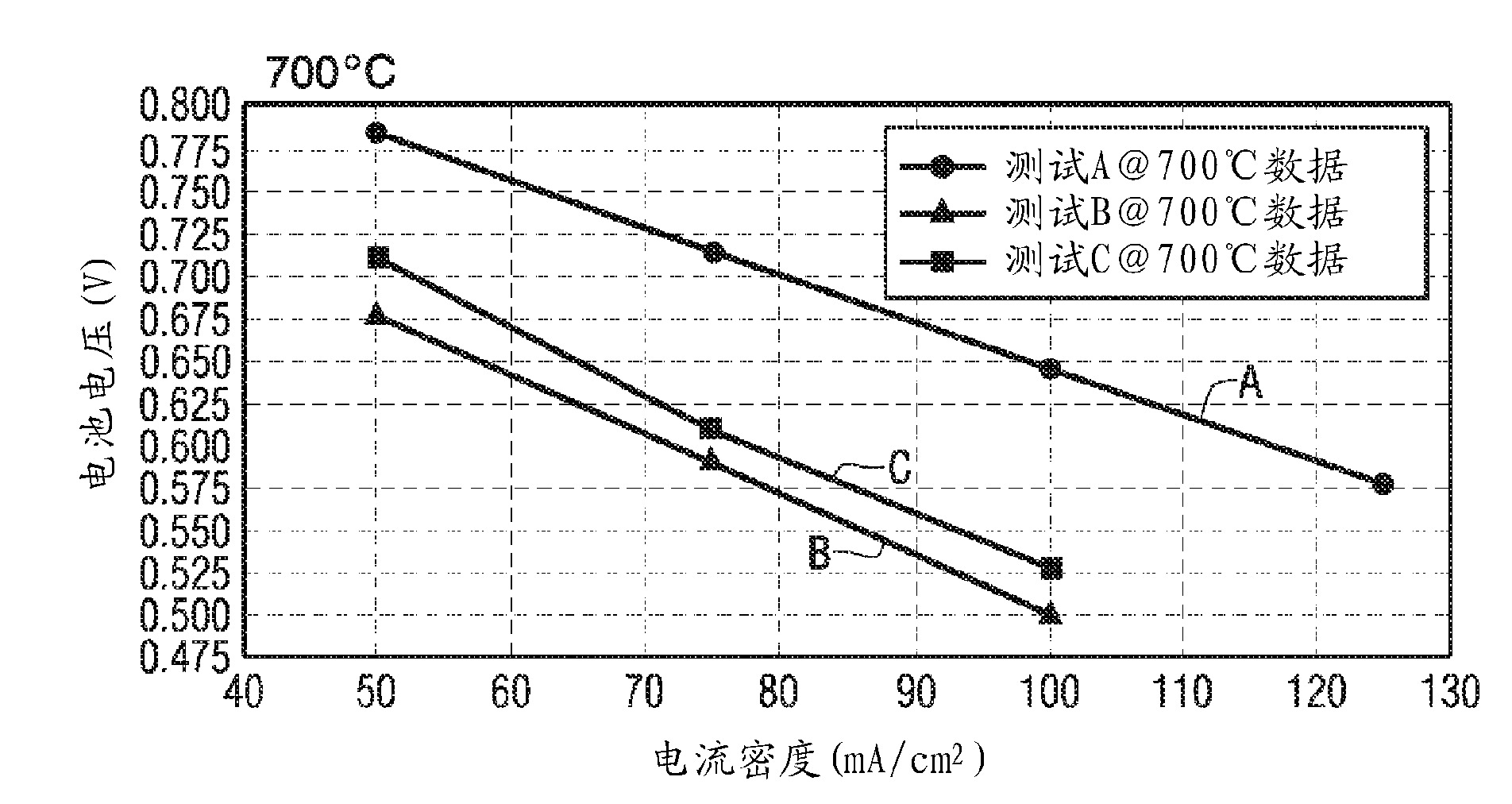

[0034] It has been found that: adding bismuth compounds to figure 1 with figure 2 The electrolyte in the solid oxide fuel cell will improve battery performance. The electrolyte in all fuel cells is arranged between the inner air electrolyte and the outer fuel electrode. It has been found that: in particular, Bi 2 O 3 It is an excellent oxygen ion conductor. Its oxygen ion conductivity is lower than ScSZ 2 orders of magnitude higher, and Bi 2 O 3 It is a good catalyst for oxygen reduction. Its presence near or at the air electrode-electrolyte interface, or as a very thin 1 to 50 micron separation interlayer between the electrolyte and the air electrode, will reduce the dynamic resistance of the battery (especially at low temperatures). Improved battery performance is expected in terms of voltage versus current density. At 100 mA / cm 2 It has shown an improvement of more than 100 mV at 700°C.

[0035] In addition, Bi 2 O 3 Effectively eliminate the microcracks in the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com