Capping assisting device

An auxiliary device and capping technology, which can be applied to measurement devices, microstructure devices, instruments, etc., can solve the problems of easy direct contact of glue with hands, reduce the efficiency of the packaging process, and overflow of glue, and achieve the goal of improving packaging efficiency and packaging reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Presented below are some of the many possible embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection.

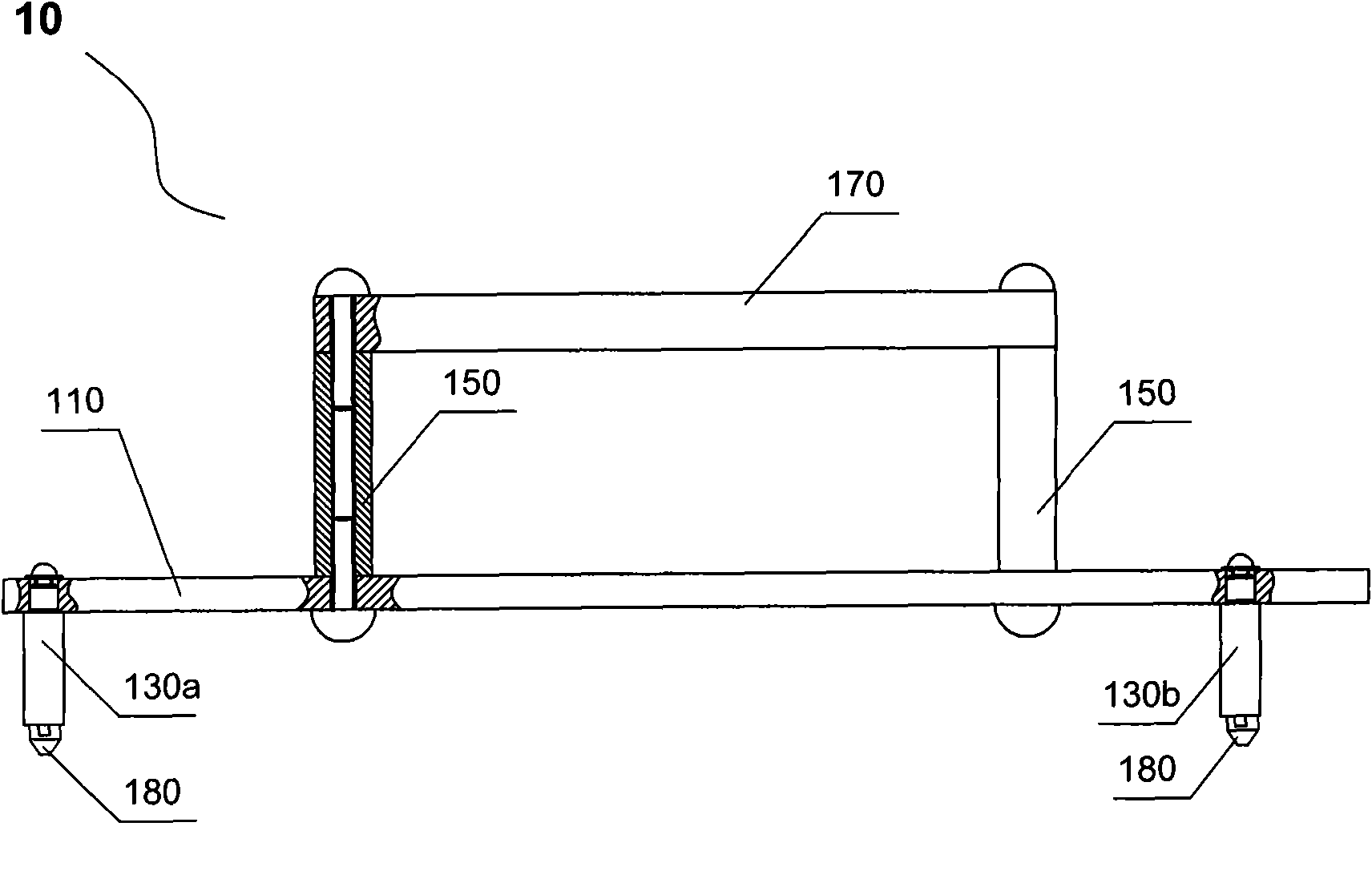

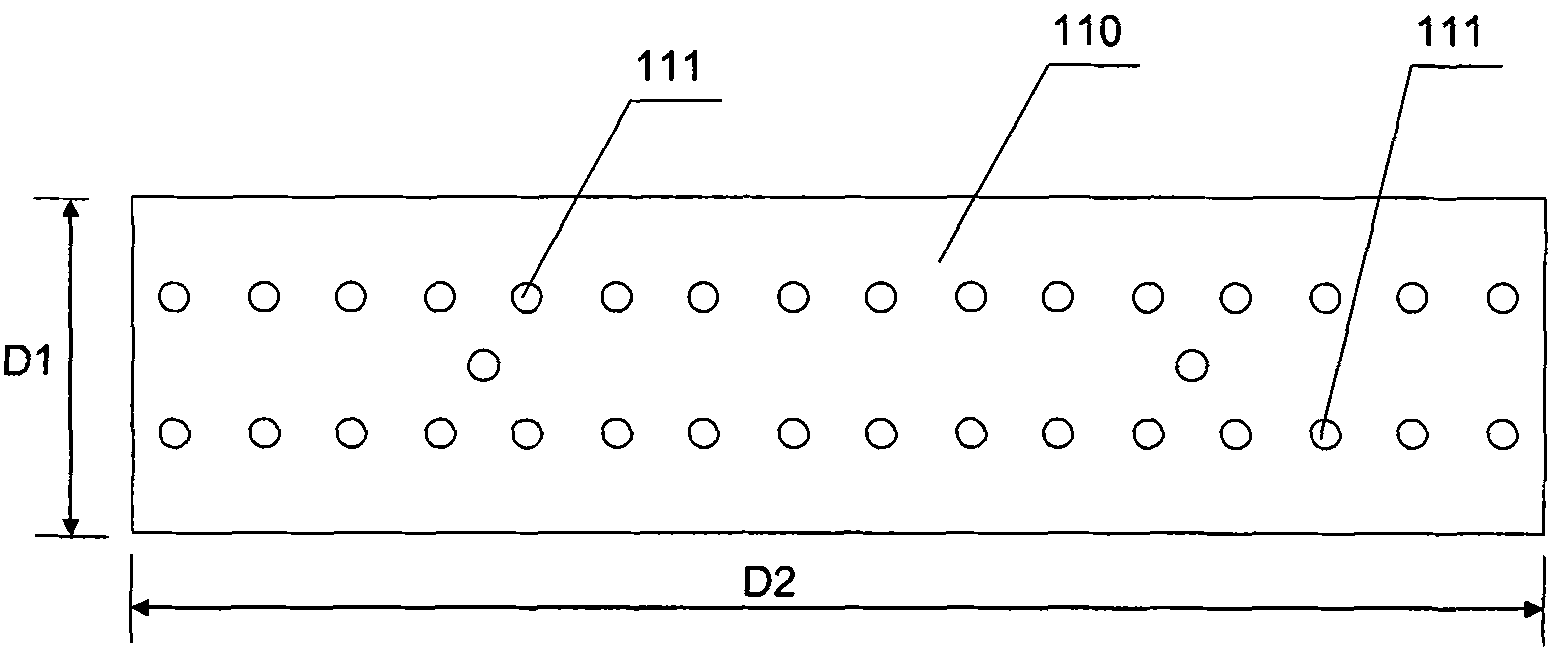

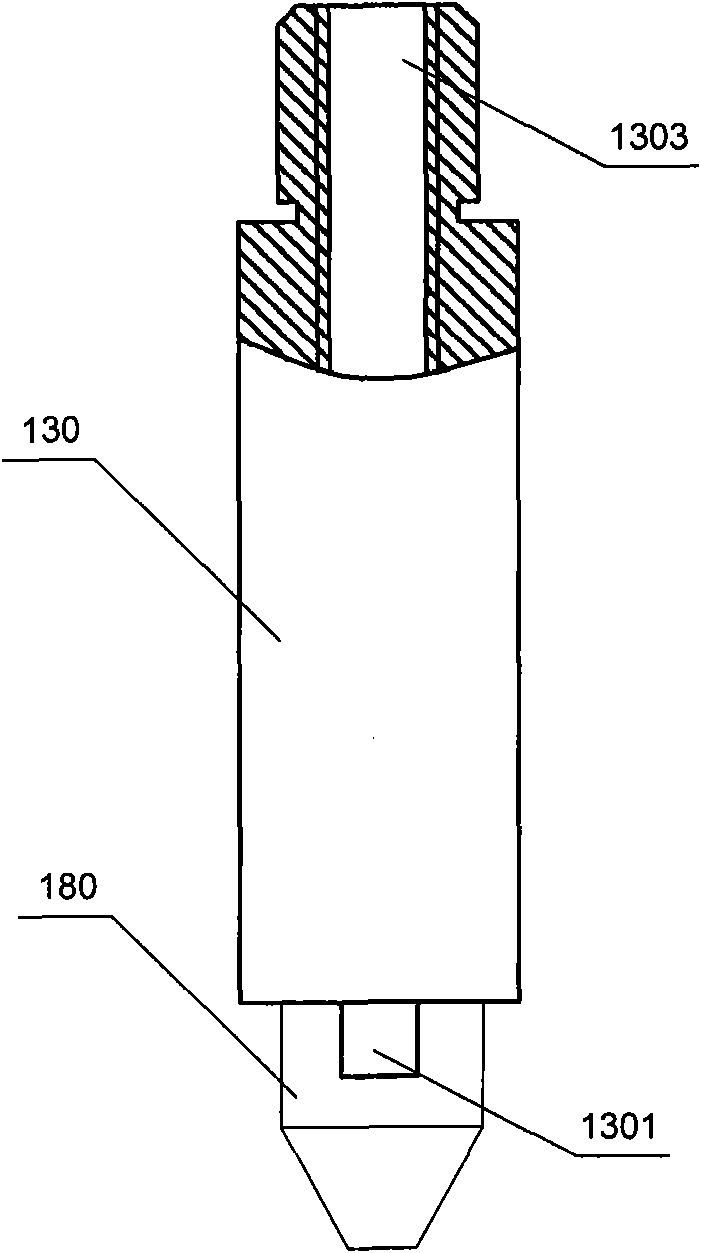

[0032] figure 1 Shown is a schematic structural view of the capping auxiliary device provided according to the embodiment of the present invention. In this embodiment, the MEMS chip is packaged with an OCDIP lead frame, but the specific package form and the corresponding specific lead frame type are not limiting. For example, in addition to the OCDIP (Open Cap Dual In_line Package) package shown in this embodiment, OCSOP (Open Cap Small Outline Package Six Leads) with 6 pins or 14 pins can also be used. , Small outline package) and other packaging forms. Because in the capping step, all MEMS chips on the lead frame array are capped and packaged at the same time, therefore, in order to improve efficiency, figure 1 The i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap