Display, polymer dispersion liquid crystal film and manufacturing method and driving method of display

A technology for dispersing liquid crystals and manufacturing methods, applied in chemical instruments and methods, liquid crystal materials, instruments, etc., can solve the problem that PDLC films cannot be widely used in the field of liquid crystal display, etc., to overcome the slow response speed, expand the application range, and accelerate the response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

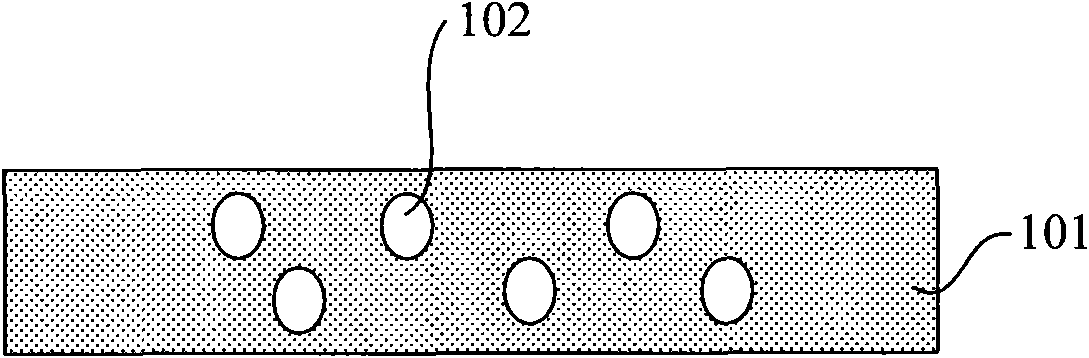

[0038] Figure 1A The schematic structural diagram of the PDLC film provided by Embodiment 1 of the present invention, such as Figure 1A As shown, the PDLC film includes: a polymer 101 and a dual-frequency liquid crystal 102 distributed in the polymer 101 . Wherein, in the PDLC film, the refractive index of the dual-frequency liquid crystal 102 along the long-axis direction matches that of the polymer 101, or the refractive index of the dual-frequency liquid crystal 102 along the short-axis direction matches that of the polymer 101. Wherein, the "matching" in each embodiment of the present invention refers to being identical or approximately identical. Wherein, the polymer 101 is an optically isotropic substance produced by a photopolymerization reaction of a photopolymerizable matrix and the like. Dual-frequency liquid crystal 102 refers to a special liquid crystal material whose electro-optical characteristics are related to frequency. The dual-frequency liquid crystal 102...

Embodiment 2

[0048] image 3 It is a flowchart of a method for manufacturing a PDLC film provided in Embodiment 2 of the present invention. Such as image 3 As shown, the manufacturing method of the PDLC film of the present embodiment comprises:

[0049] Step 301, uniformly mixing the dual-frequency liquid crystal, the photopolymerizable matrix, the nano-beads and the photoinitiator to form a uniform mixture;

[0050] Step 302, rolling the homogeneous mixture between the first film layer and the second film layer;

[0051] Step 303 , irradiating the rolled homogeneous mixture under ultraviolet light to form the PDLC film.

[0052] The method for manufacturing the PDLC film in this embodiment can be used to manufacture the PDLC film provided by the present invention. The technical solution of this embodiment adopts the PDLC film formed by uniformly mixing dual-frequency liquid crystals with photopolymerizable substrates, rolling and ultraviolet light irradiation, and utilizes the differ...

Embodiment 3

[0059] Figure 4 The process flow of the method for driving a PDLC film provided in Embodiment 3 of the present invention. Such as Figure 4 shown, including:

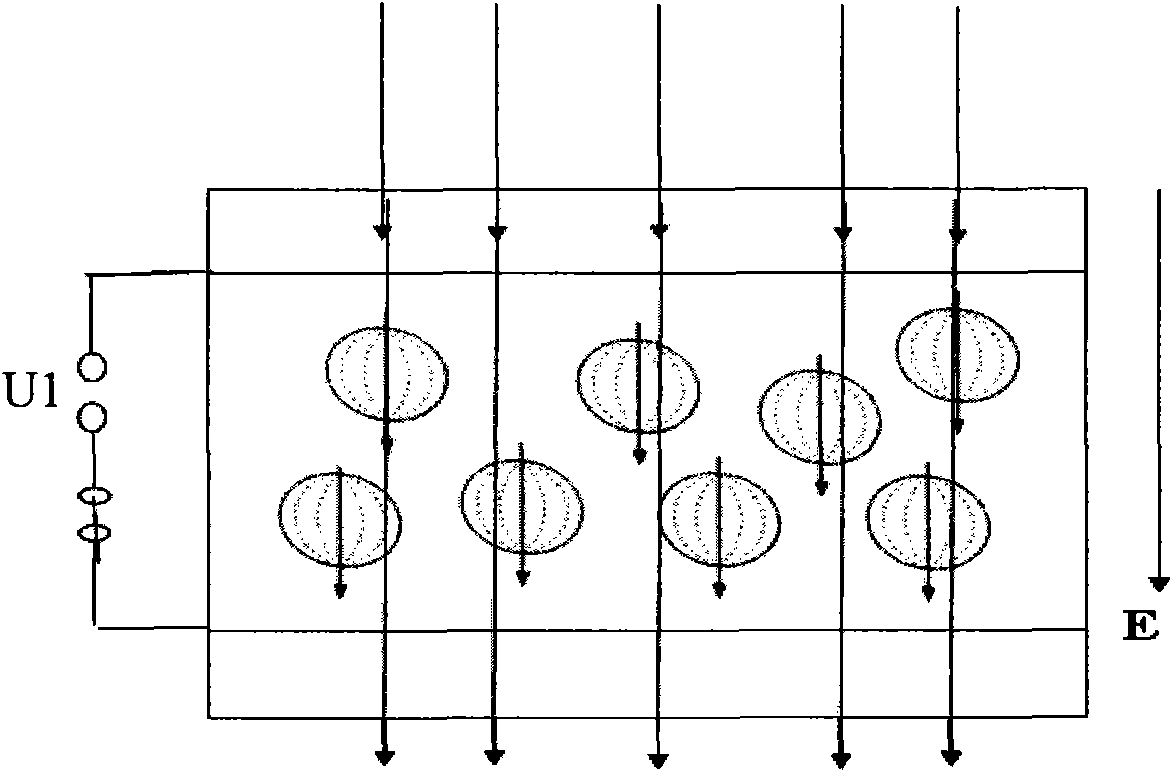

[0060] Step 401, using a voltage of a first frequency to drive the PDLC film, so that the PDLC film assumes a transmissive state;

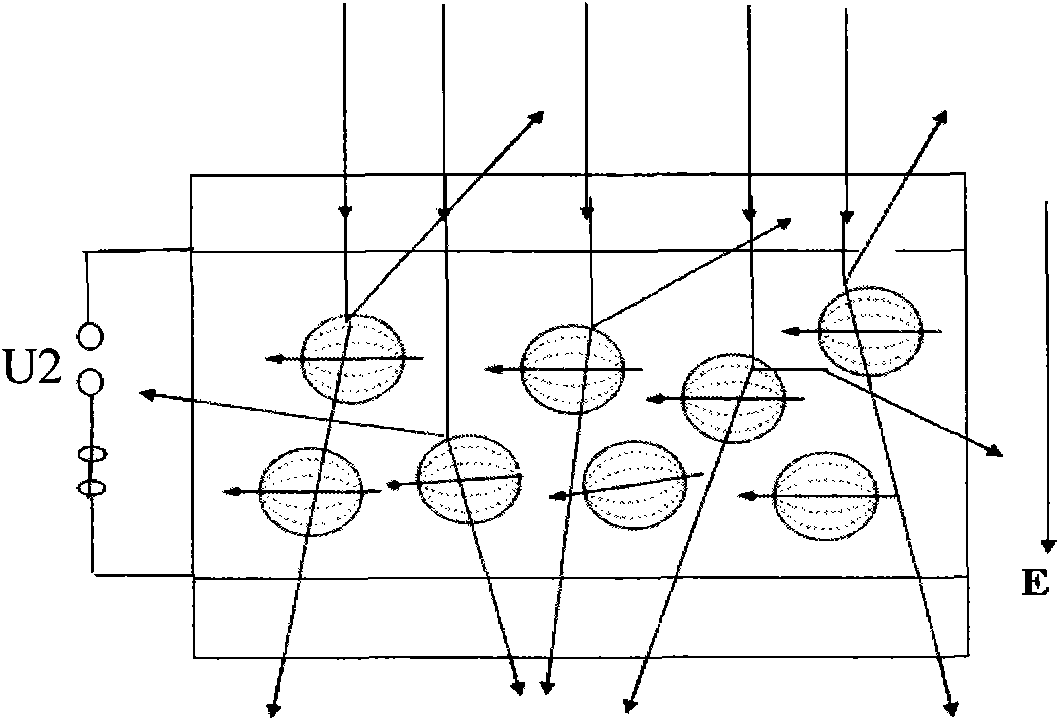

[0061] Step 402 , using a voltage of a second frequency to drive the PDLC film in the transmission state, so that the PDLC film changes from the transmission state to the scattering state.

[0062]Wherein, the voltage of the first frequency and the voltage of the second frequency in this embodiment may be determined according to the characteristics of the dual-frequency liquid crystal in the PDLC film used. Specifically, in combination with the PDLC film provided by the above-mentioned embodiments of the present invention, when the refractive index of the dual-frequency liquid crystal in the PDLC film along the long axis direction matches the refractive index of the polymer in the PDLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com