Water electrolysis system

A water electrolysis and water electrolysis technology, applied in the field of water electrolysis systems, can solve the problems of inability to withstand high-pressure hydrogen pressure, and the detection accuracy of optical sensors is reduced, and achieves the effects of good gas-liquid separation, improved strength and rigidity, and correct water level measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

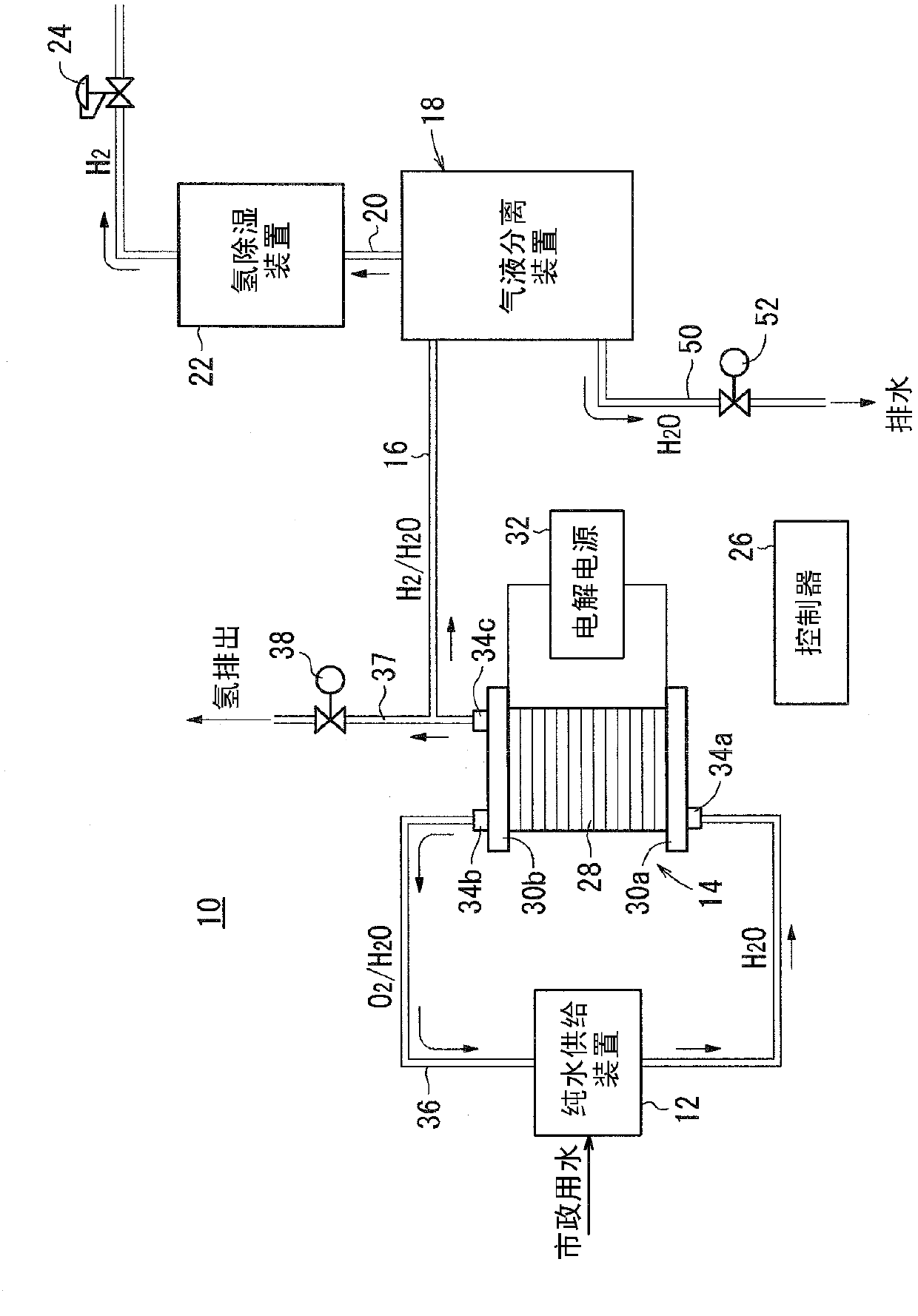

[0070] Such as figure 1 As shown, the water electrolysis system 10 according to the first embodiment of the present invention includes a high-pressure water electrolysis device 14 supplied with pure water generated from municipal water via a pure water supply device 12, and electrolyzes the pure water And produce high-pressure hydrogen (higher pressure than oxygen pressure, for example, 1MPa~70MPa).

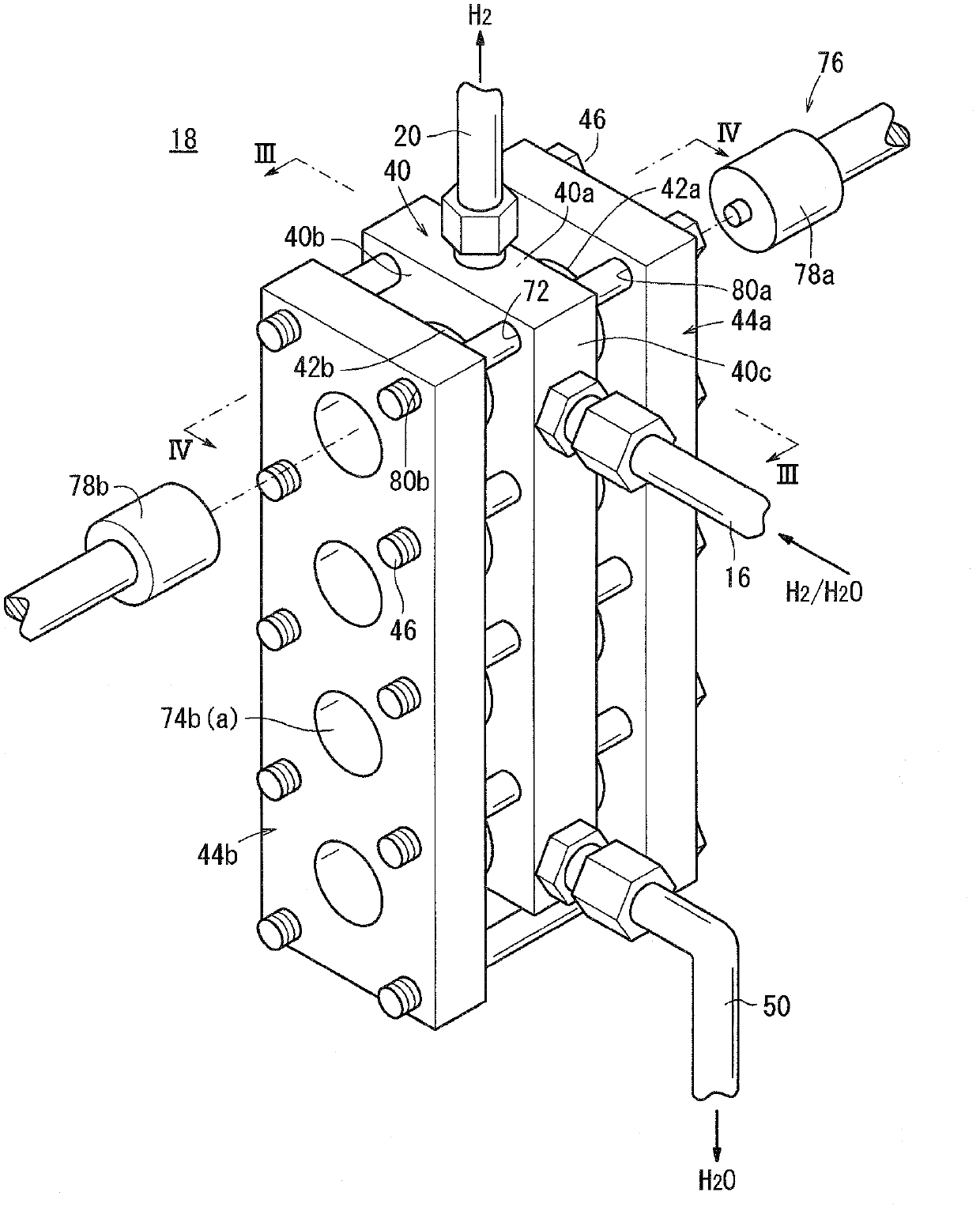

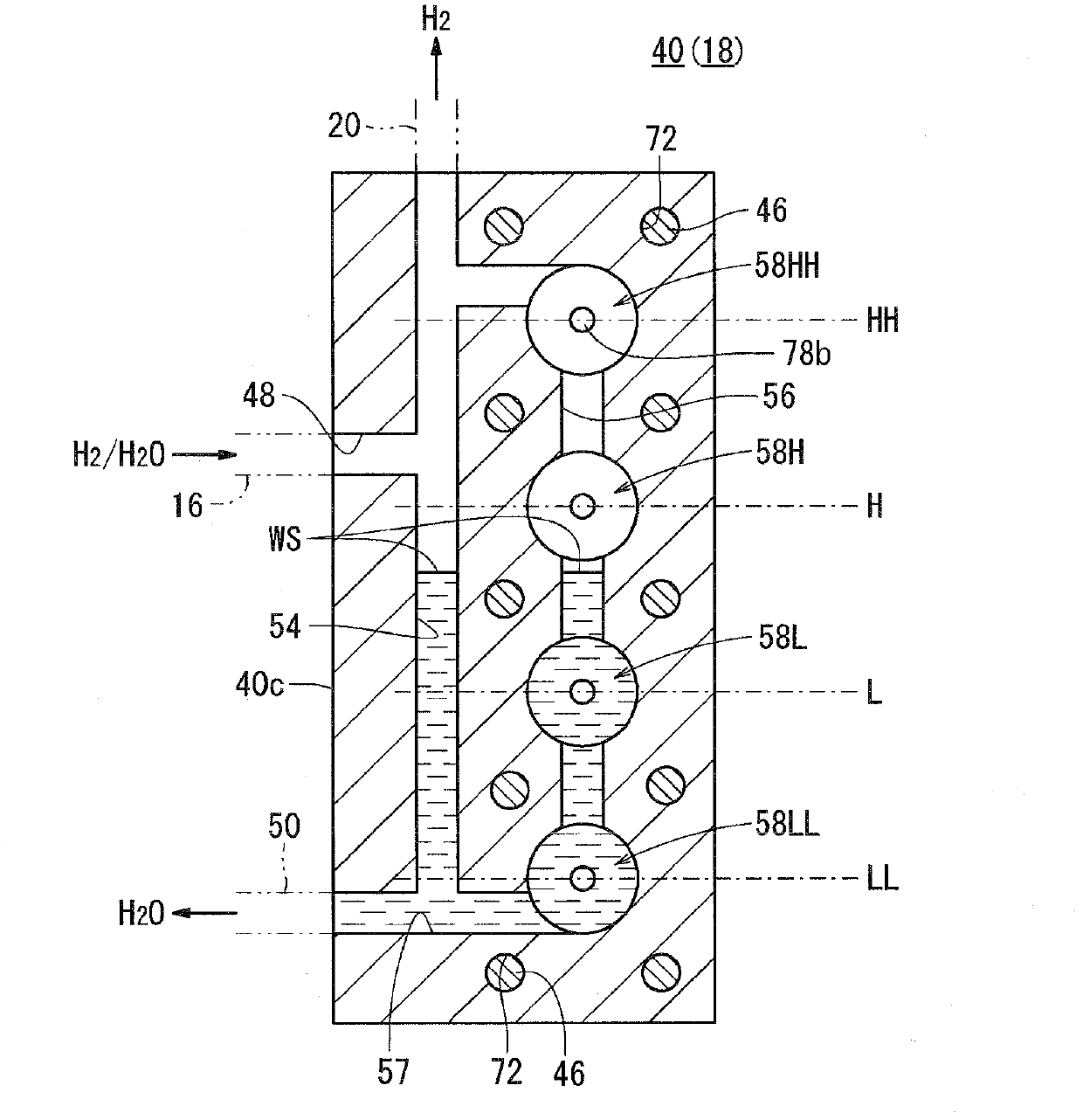

[0071] The water electrolysis system 10 is further equipped with: a gas-liquid separation device 18, which removes moisture contained in hydrogen derived from the high-pressure water electrolysis device 14 to the hydrogen lead-out path 16; a hydrogen dehumidification device (for example, a water adsorption device) 22, which removes moisture from The gas-liquid separation device 18 is led out to the hydrogen pipe 20 to absorb and remove the moisture contained in the hydrogen; the back pressure valve 24 is arranged downstream of the hydrogen dehumidification device 22, and the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com