Melt spinning production method and device with online addition of color master

A technology of adding melt and production equipment, applied in melt spinning, adding pigments to spinning solution, adding dyes to spinning solution, etc., can solve the problems of poor color fastness of colored silk, high energy consumption in bleaching and dyeing operations, and problems in bleaching and dyeing. Process pollution and other problems, to achieve the effect of reducing energy consumption and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

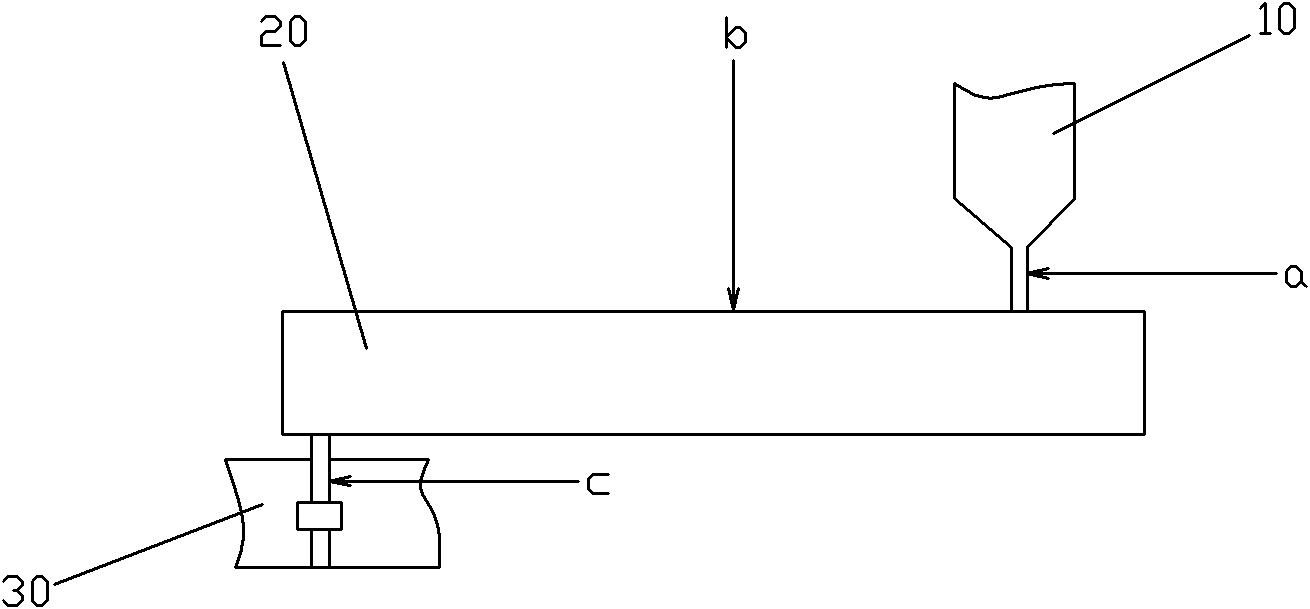

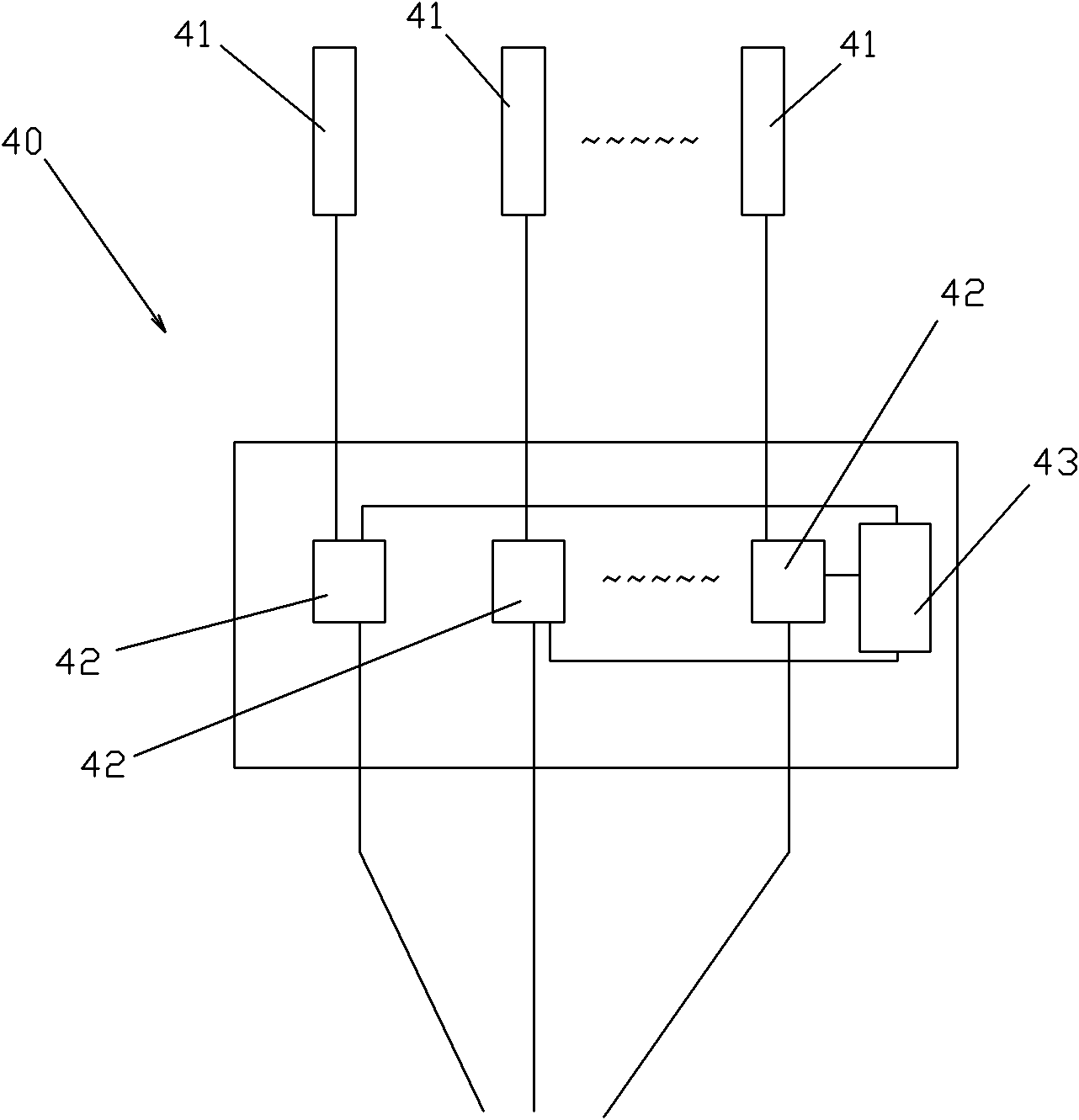

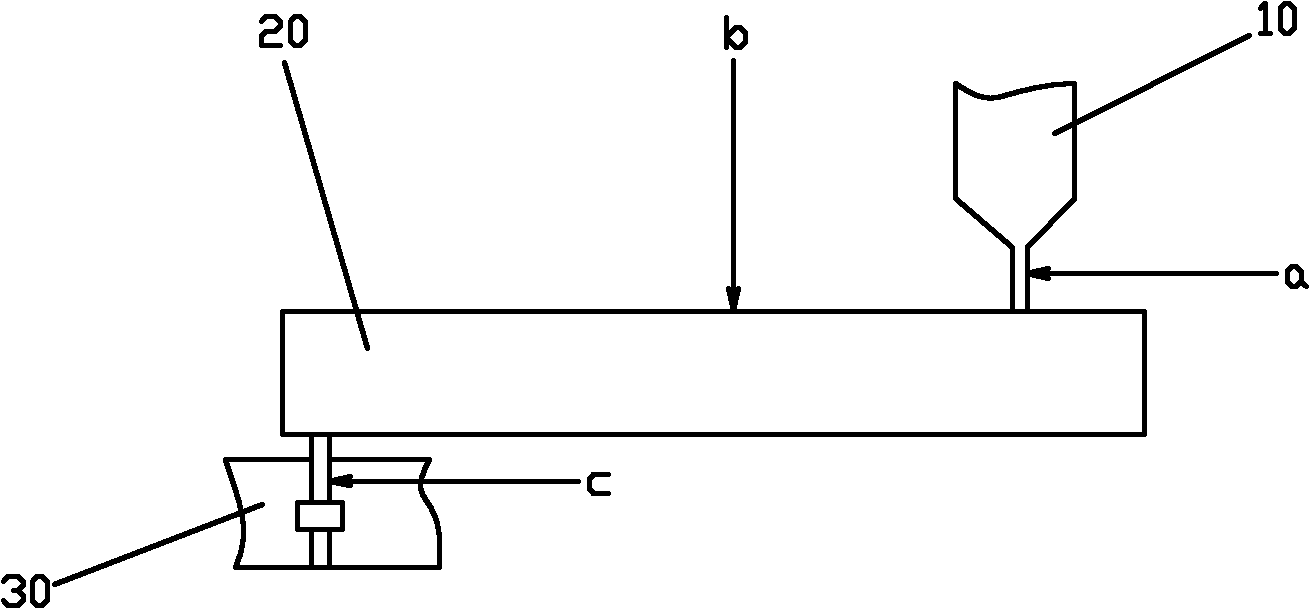

[0015] refer to figure 1 and figure 2 , an on-line color masterbatch adding melt spinning production device of the present invention includes a polymer hopper 10, a screw extruder 20, a spinning box 30 and a liquid color masterbatch adding unit 40, and the liquid color masterbatch adding unit 40 can be respectively Set at the feeding port a of the screw extruder 20 or the feeding section of the screw extruder 20 close to the plasticizing section b or the entrance c of the spinning box, a, b, and c have their own advantages and disadvantages, as follows:

[0016] Place a: It is simple and convenient to add liquid color masterbatch at this place, and the modification of spinning equipment is minimal, as long as the liquid color masterbatch delivery pipe is connected to the feeding port. In the previous technology, the color masterbatch is usually added here. However, since the liquid color masterbatch will reduce the friction coefficient of the plastic and the screw, the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com