Wire-welding device for cable head

A wire welding device and cable head technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor welding wire quality and low work efficiency, improve quality and work efficiency, facilitate portability, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

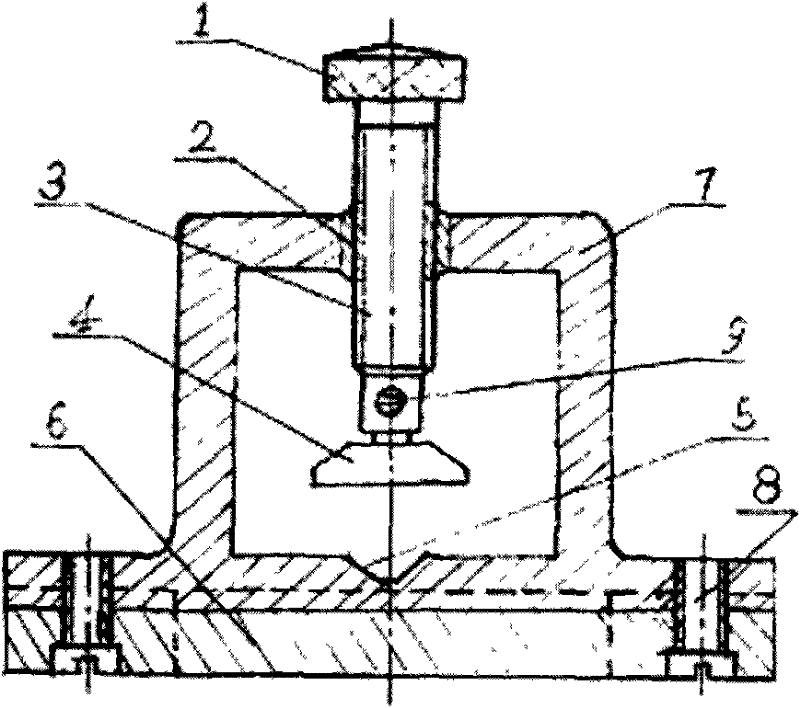

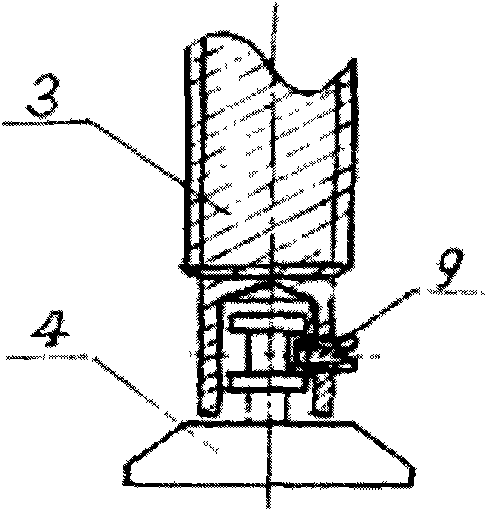

[0015] Fasten the mouth-shaped bracket (7) on the base (6) with bolts (8), screw the screw rod (3) with the handle (1) on the upper end from the nut (2) and connect it to the mouth-shaped bracket ( 7), insert the part of the cylindrical rod with the annular groove on the movable platen (4) into the central counterbore, screw the screw (9) into the threaded hole and screw it into the annular groove of the cylindrical rod for positioning and movable connection, and move The pressing plate can rotate freely around the axis of the cylindrical rod, so that when the handle (1) rotates left and right, the movable pressing plate (4) also rotates thereupon. So far the installation of the cable head welding device is completed.

[0016] When in use, put the cable head on the fixed groove (5) in the middle of the cuboid at the bottom of the mouth-shaped bracket, turn the handle (1) to move the movable pressure plate (4) down and press it on the cable head, and then perform welding by one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com