Method for preparing zirconia heat insulation material by using eiderdown as template

A technology of thermal insulation material and zirconia, applied in zirconia and other directions, can solve problems such as unfavorable locking air thermal insulation performance, and achieve the effects of low preparation temperature, broad research and application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

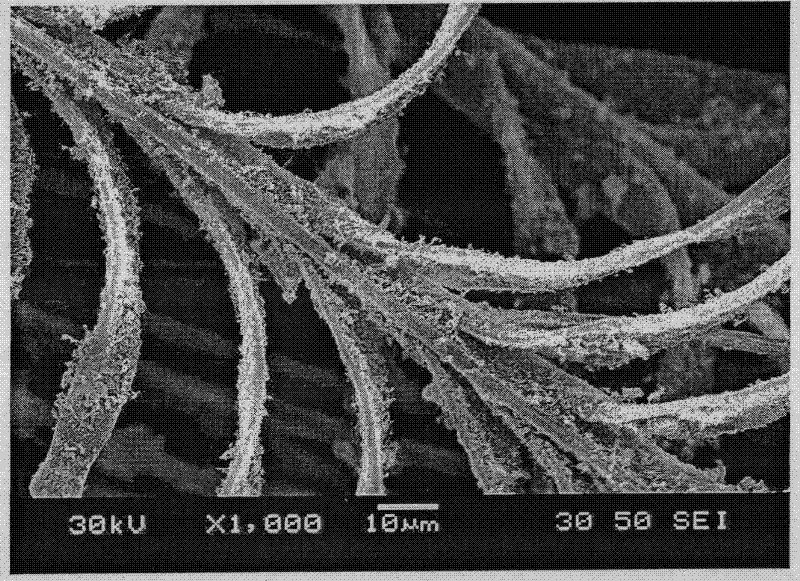

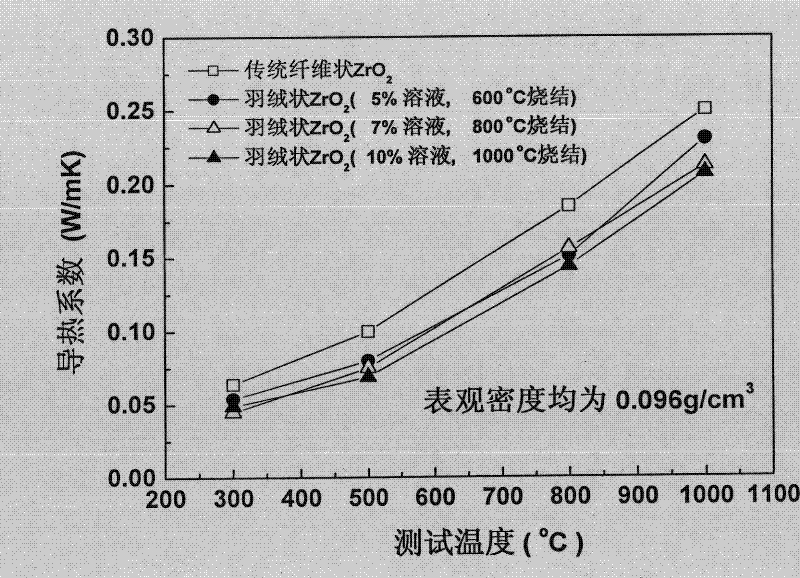

[0020] The preparation mass percent concentration is 5% Zr(NO 3 ) 4 solution, soak the dried down in the solution for 5 minutes, and stir it slightly to accelerate the dispersion speed of the solution in the down, squeeze the soaked down in the filter to remove the excess solution, and then put it into the drying box Dry in the temperature range of 50 ° C for 48 hours, put the dried down in a crucible, and sinter and oxidize it in an electric furnace at a temperature of 600 ° C to obtain a down-like ZrO 2 Insulation materials. Prepared ZrO 2 Scanning electron microscope photographs of the microscopic morphology as figure 1 As shown, it can be seen from the figure that the material maintains the dendritic structure of down. The down-like ZrO measured 2 Compared with traditional fibrous ZrO 2 Thermal conductivity as figure 2 As shown, it can be seen from the figure that the feather-like ZrO 2 (5% solution, sintered at 600°C) has significantly lower thermal conductivity ...

Embodiment 2

[0022] The preparation mass percent concentration is 10% Zr(NO 3 ) 4 Solution, soak the dried down in the solution for 48 hours, and stir it slightly to accelerate the dispersion speed of the solution in the down, squeeze the soaked down in the filter to remove the excess solution, and then put it into the drying box Dry in a temperature range of 100°C for 3 hours, put the dried down in a crucible, and sinter and oxidize it in an electric furnace at a temperature of 1000°C to obtain down-like ZrO 2 Insulation materials. The down-like ZrO measured 2 Compared with traditional fibrous ZrO 2 Thermal conductivity as figure 2 As shown, it can be seen from the figure that the feather-like ZrO 2 (10% solution, sintered at 1000°C) has significantly lower thermal conductivity than traditional fibrous ZrO 2 , indicating a better thermal insulation effect.

Embodiment 3

[0024] The preparation mass percentage concentration is 7%Zr(NO 3 ) 4 Solution, soak the dried down in the solution for 24 hours, and stir it slightly to accelerate the dispersion speed of the solution in the down, squeeze the soaked down in the filter to remove the excess solution, and then put it in the drying box Dry in a temperature range of 75°C for 25 hours, place the dried down in a crucible, and sinter and oxidize it in an electric furnace at a temperature of 800°C to obtain down-like ZrO 2 Insulation materials. The down-like ZrO measured 2 Compared with traditional fibrous ZrO 2 Thermal conductivity as figure 2 As shown, it can be seen from the figure that the feather-like ZrO 2 (7% solution, sintered at 800°C) has significantly lower thermal conductivity than traditional fibrous ZrO 2 , indicating a better thermal insulation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com