Waste polypropylene modified thin-walled corrugated tube and manufacture method thereof

A waste polypropylene and corrugated pipe technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of producing thin-walled corrugated pipes and the inability to use waste polypropylene, etc., and achieve low production costs and joining methods Simple and cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A waste polypropylene modified thin-wall corrugated pipe, which is made by using waste polypropylene modified to strengthen and toughen to improve the melt strength and then melted and extruded through a plastic extruder to form the components of the waste polypropylene modified thin-wall corrugated pipe The content is calculated in parts by weight as:

[0040] 97 parts of modified polypropylene, 3 parts of antioxidant;

[0041] The modified polypropylene is mixed with waste polypropylene, modified auxiliary agent peroxide masterbatch, small molecule monomer masterbatch, and calcium stearate, and the content of each component of the modified polypropylene is expressed in parts by weight Calculated as:

[0042] 75 parts of waste polypropylene, 4 parts of peroxide masterbatch, 20 parts of total small molecule monomer masterbatch, 0.4 part of stearate;

[0043] The peroxide masterbatch is a masterbatch made of activated inorganic powder as a carrier, mixed with peroxide,...

Embodiment 2 Embodiment 6

[0050]The waste polypropylene modified thin-walled corrugated pipe with different components content is made by using waste polypropylene modified to strengthen and toughen to improve the melt strength, and then melted and extruded through a plastic extruder to form a waste polypropylene modified thin-walled corrugated pipe. The content of each component is calculated in parts by weight:

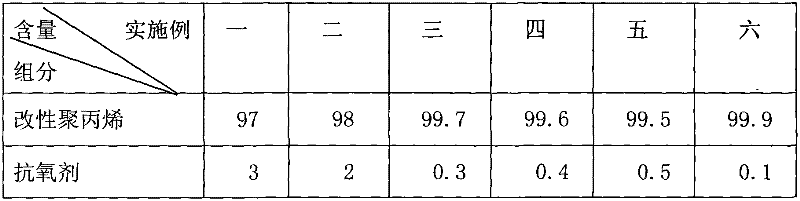

[0051] 97-99.9 parts of modified polypropylene, 0.1-3 parts of antioxidant; (see attached table 1)

[0052] The modified polypropylene is mixed with waste polypropylene, modified auxiliary agent peroxide masterbatch, small molecule monomer masterbatch, and calcium stearate, and the content of each component of the modified polypropylene is expressed in parts by weight Calculated as:

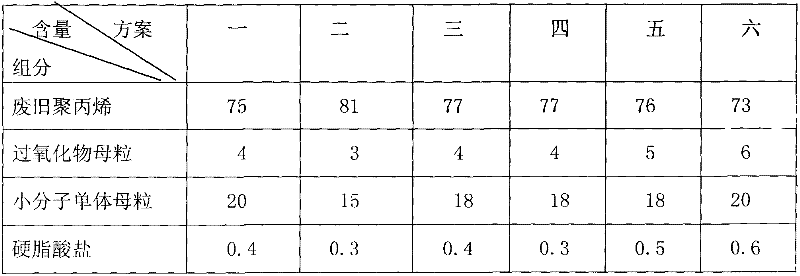

[0053] 73-81 parts of waste polypropylene, 3-6 parts of peroxide masterbatch, 15-20 parts of small molecule monomer masterbatch, 0.3-0.6 part of stearate; (see attached table 2)

[0054] The peroxide masterba...

Embodiment 7

[0061] A method for manufacturing waste and old polypropylene modified thin-walled corrugated pipes, the method is to use waste and old polypropylene to modify, strengthen and toughen to improve the melt strength, and then melt and extrude the waste and old polypropylene modified thin-walled pipe through a plastic extruder. Wall bellows, the specific method comprises the following steps:

[0062] ①, making activated inorganic powder

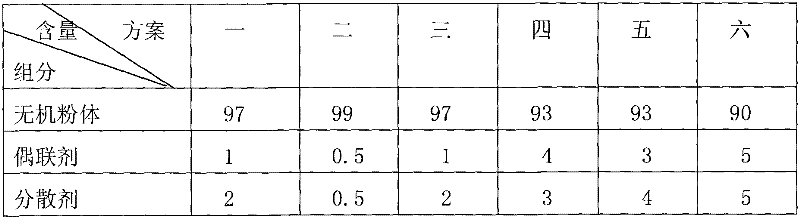

[0063] Take 90-99 parts of inorganic powder, 0.5-5 parts of coupling agent, and 0.5-5 parts of dispersant, put the above-mentioned inorganic powder, coupling agent and dispersant in a stirrer and stir until 90-100°C out of the pot to get Activated inorganic powder;

[0064] ②. Making modified additive peroxide masterbatch

[0065] Take 70 parts of activated inorganic powder, 10 parts of peroxide, and 20 parts of thermoplastic elastomer, put the thermoplastic elastomer into the internal mixer, heat and stir until molten state, cool to below 140°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com