Double-sided adhesive tape

A tape, double-sided technology, applied in the field of adhesive tape, can solve the problems of sheet pollution, sheet deformation, damage, etc., and achieve the effect of excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0065] The present invention is described in more detail below by way of examples. It should be pointed out that these embodiments are only illustrative descriptions of the present invention, and do not constitute any limitation to the present invention. Unless otherwise specified, the percentages, contents, ratios, etc. used in the present invention are all by weight, and the temperatures used are all in degrees Celsius.

[0066] First, summarized below are abbreviations of chemical substances used in the following preparation examples.

[0067] 2EHA: Isooctyl acrylate (manufactured by BASF Corporation)

[0068] AA: Acrylic (manufactured by BASF Corporation)

[0069] EtOAc: Ethyl acetate (manufactured by Shanghai Reagent Company)

[0070] ADVN: 2,2'-azobis(2,4-dimethylvaleronitrile) (azo-type polymerization initiator, manufactured by Wako Pure Chemical Industries, Ltd.)

[0071] Foral TM 85: Tackifier (manufactured by American Eastman Company)

[0072] Irganox TM 1076:...

example 1

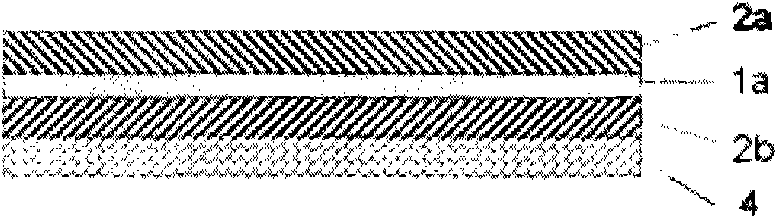

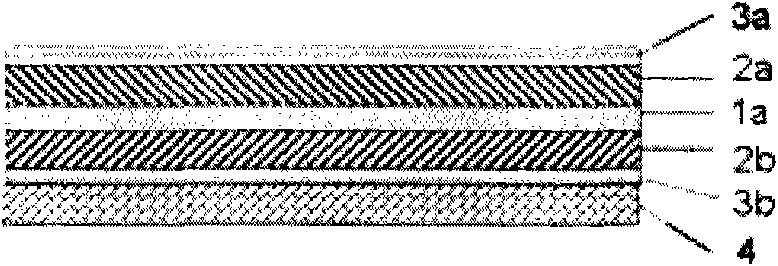

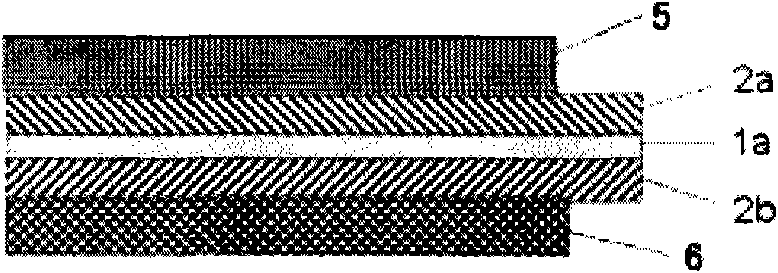

[0076] Adopt the VHB produced by 3M Company on the market TM 4608 acrylic as the first and second adhesive element layers, the VHB TM 4608 Acrylic is a copolymer of isooctyl acrylate and acrylic acid, both the first and second adhesive element layers have a thickness of 800 μm. Adopt PE80 linear low density polyethylene film with 80μm thickness. PE80 uses double-sided corona to improve the adhesion between it and double-sided tape, and 4608 is pressed on the front and back of PE80 by hot pressing. The total thickness of the finished product is 1,680 μm. The adhesive layer on both sides is covered with a PET release film.

example 2

[0078] 90 grams of isooctyl acrylate, 10 grams of acrylic acid were added to a 2000 ml separable flask, followed by 0.12 grams of ADVN: 2,2'-azobis(2,4 dimethylvaleronitrile) and 150 grams of acetic acid Ethyl ester was charged thereinto, and a polymerization reaction was carried out for 8 hours in a normal-temperature water bath maintained at 65° C. while blowing nitrogen gas from the lower part of the blended solution with a Pasteur pipette. Coat the above-mentioned obtained glue on a 50 μm thick PET release film with a coating thickness of 120 μm, and dry it in an oven at 105° C. for 10 minutes. After taking it out, attach the pressure-sensitive adhesive layer to the surface of the adhesive tape prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com