Steel used for steam turbine blades and manufacturing method thereof

A technology for steam turbine blades and manufacturing methods, which is applied in the field of high-performance medium-carbon martensitic stainless steel and its manufacturing, and can solve the problems of not meeting the development requirements of blade steel, reducing safety, and low high-temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described below by specific embodiment:

[0045] Embodiments of the present invention include the following steps:

[0046] 1) Conventional smelting

[0047] Get the required elements and adjust the content of each element in the smelting process according to the EF+AOD+(LFV) process route, so that its mass percentage is as shown in Table 1:

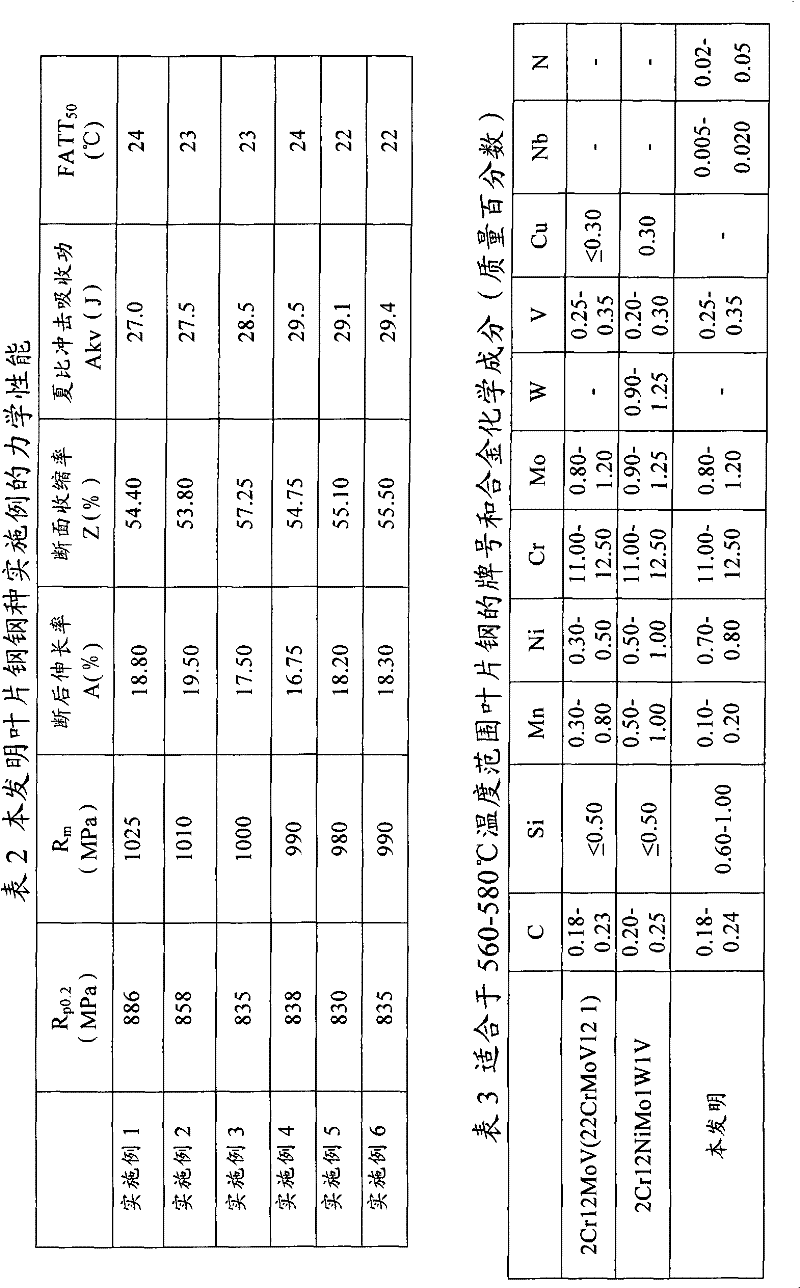

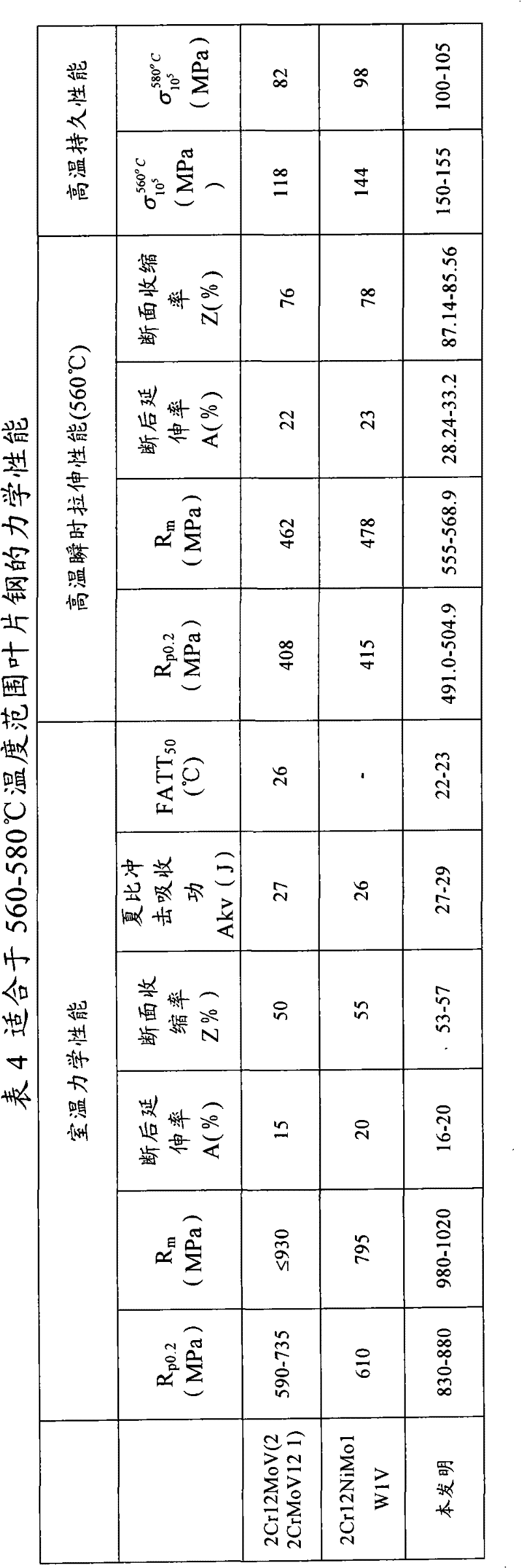

[0048] Table 1 The alloy composition (mass percentage) of blade steel of the embodiment of the present invention

[0049] C

Si

mn

P

Cr

Ni

Mo

V

Nb

N

Example 1

0.24

1.00

0.12

0.02

11.23

0.79

1.10

0.28

0.020

0.05

Example 2

0.22

0.85

0.15

0.01

11.30

0.76

0.93

0.28

0.010

0.04

Example 3

0.20

0.78

0.14

0.01

11.48

0.78

0.89

0.30

0.015

0.05

Example 4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com