Indoor experimental simulation method for testing injection pressure drop of coal bed gas

A technology of experimental simulation and coalbed methane, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve problems such as high cost, lack of strict demonstration and exact data description, and achieve the effect of optimizing test parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

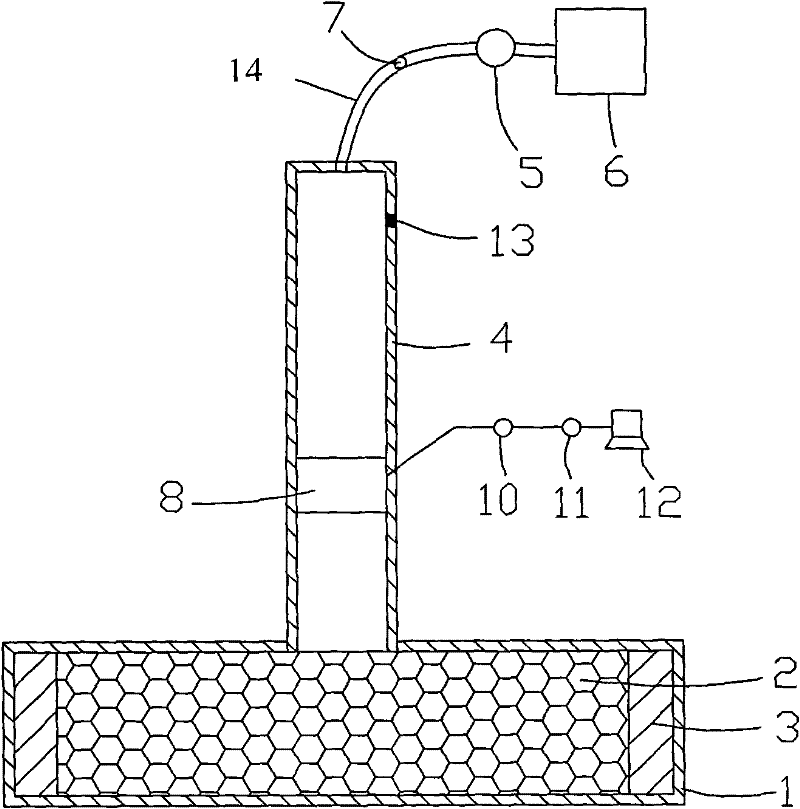

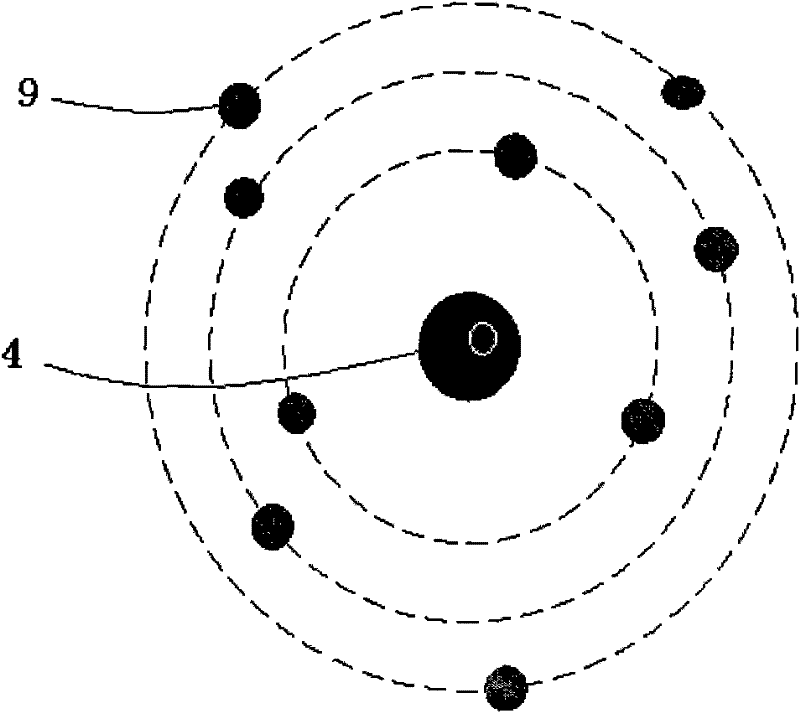

[0023] refer to figure 1 with figure 2 , this embodiment provides an indoor experimental simulation method for the pressure drop test of coalbed methane injection, the simulation device for the pressure drop test of coalbed methane injection used in the method includes: a coalbed simulation device, an injection system, a pressure sensor and a data acquisition system.

[0024] The coal seam simulation device is used to simulate the coal seam in the area to be tested. The coal seam simulation device includes a casing 1, and a rubber elastic body 3 is arranged on the side of the inner wall of the casing 1 to simulate the elasticity of the coal seam. In the space surrounded by the casing 1 A plurality of hollow rubber balls 2 are provided, and the air in the hollow rubber balls 2 is used to simulate gas compressibility, and coal seams with different permeability are simulated by changing the size of the filled hollow rubber balls 2, and a gap is left on the upper surface of the s...

Embodiment 2

[0037] Simulating medium and high permeability coal seams: the permeability of the coal seam to be simulated is about 10mD, and the elastic modulus of the coal seam is about 1000MPa, which is a medium and high permeability coal seam. The rubber elastic body 3 which is equivalent to the elasticity of the coal seam is arranged close to the inner side wall of the casing 1, and the space formed by the rubber elastic body 3 casing 1 and the rubber elastic body 3 is filled with a hollow rubber ball 2 with a radius of 2 mm to form a medium-high Permeability simulated coal seams.

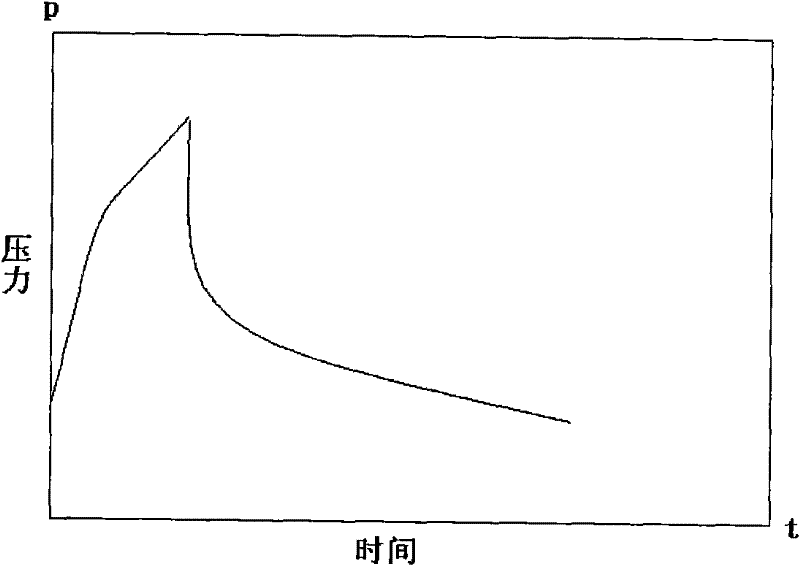

[0038] Injection stage: control the flow tester 7 to inject water into the injection wellbore 4 at a rate of 1ml / min for 5 minutes;

[0039] Pressure drop stage: stop the injection after 5 minutes of water injection, and end the simulation test after 10 minutes.

[0040] In the injection stage and the pressure drop stage, the pressure sensor 9 is used to monitor the pressure change with time in the injecti...

Embodiment 3

[0044] Simulating medium and high permeability coal seams: the permeability of the coal seam to be simulated is about 10mD, and the elastic modulus of the coal seam is about 1000MPa, which is a medium and high permeability coal seam. The rubber elastic body 3 which is equivalent to the elasticity of the coal seam is arranged close to the inner side wall of the casing 1, and the space formed by the rubber elastic body 3 casing 1 and the rubber elastic body 3 is filled with a hollow rubber ball 2 with a radius of 2 mm to form a medium-high Permeability simulated coal seams.

[0045] Injection stage: control the flow tester 7 to inject water into the injection wellbore 4 for 2.5 minutes at a rate of 2ml / min;

[0046] Pressure drop stage: stop the injection after 2.5 minutes of water injection, and end the simulation test after 5 minutes.

[0047] In the injection stage and the pressure drop stage, the pressure sensor 9 is used to monitor the pressure change with time in the inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com