High-efficiency high-voltage vertical through hole bonding type light emitting diode (LED) chip and manufacture method thereof

An LED chip and vertical through-hole technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of long-term use of high-power LEDs, cumbersome processes, differences in thermal expansion coefficients, etc., to reduce the number of packaging wires, increase Light-emitting area and efficiency, the effect of improving light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0024] Making the structure of the LED chip according to the first embodiment of the present invention comprises the following steps:

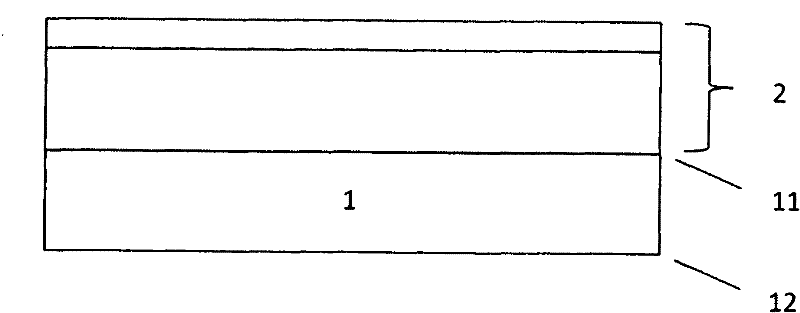

[0025] figure 1 It is a light emitting epitaxial layer 2 formed on the substrate 1 and its first surface 11 of the LED chip according to the first embodiment of the present invention. The light emitting epitaxial layer is a light emitting structure for LED well known to those skilled in the art, such as group IIIV Compound semiconductor light-emitting structures, etc. The emitted light includes light propagating away from the substrate and light propagating toward the substrate 1 , and the light propagating toward the substrate at least partially passes through the substrate 1 .

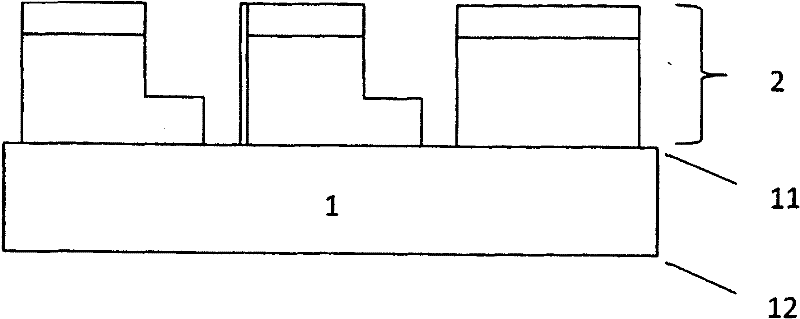

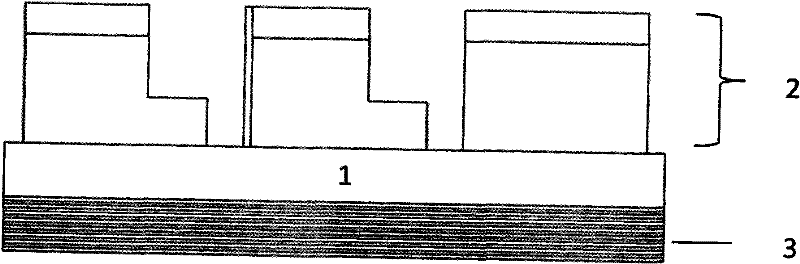

[0026] figure 2 It shows that the LED chip according to the first embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com