Lithium ion battery electrode composite material and preparation method and battery thereof

A technology for lithium ion batteries and composite materials, applied in the field of lithium ion battery electrode composite materials and their preparation, can solve the problems of poor cycle performance of lithium ion batteries, insufficient uniformity of aluminum phosphate coating layer, etc., to improve thermal stability and The effect of maintaining battery capacity and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: the preparation of lithium ion battery modifier

[0057] 34.5 g of 85% H 3 PO 4 and 14 grams of deionized water were added into a beaker to form a solution; the solution was magnetically stirred at 80°C for 5 minutes; 5.9 grams of Al(OH) 3 Join in the above-mentioned beaker, react 2 hours, the solution in the described beaker generates a sol-like liquid; Then, in this beaker, add 2.5 grams of CrO 3 powder, continue to react for 2 hours, so that the product in the beaker becomes a clear red solution.

[0058] (2) Application of modifiers for lithium-ion batteries

[0059] (1) For Li-ion battery current collector

[0060] The above lithium ion battery modifiers can be used to improve the stability of lithium ion batteries. Taking the current collector of lithium-ion battery as an example, since the modifier is a clear solution, it is easy to coat evenly on the surface of the current collector of lithium-ion battery, and after coating, drying and other t...

Embodiment 2

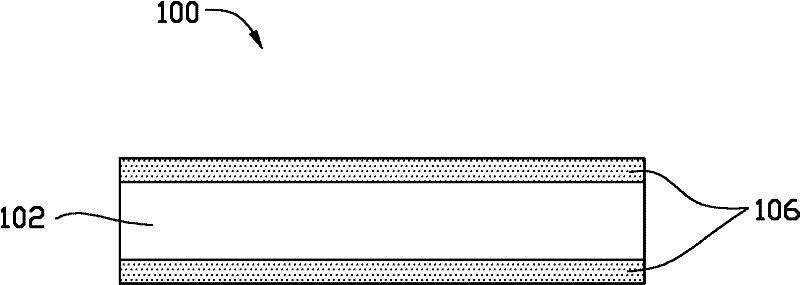

[0081] Embodiment 2: the preparation of lithium ion battery current collector

[0082] In the embodiment of the present invention, the lithium ion battery current collector with a protective film is prepared by using the above lithium ion battery modifier. In the embodiment of the present invention, aluminum foil is selected as the metal sheet, the thickness of the metal sheet is 20 μm, and the width is 30 mm. The preparation process of the lithium ion battery current collector is as follows: add 0.5ml of triton and 30ml of water to the lithium ion battery modifier prepared above, and ultrasonically vibrate for 20 minutes to make it mix uniformly; The modifier is coated on the surface of the aluminum foil to form a coating layer; then the aluminum foil with the coating layer is placed in an oven at 80°C to dry for 0.5 hours, and finally the aluminum foil with the coating layer is put into the muffle furnace, Insulated at 200° C. for 1 hour to obtain the lithium ion battery cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com