Soft polyurethane foam and manufacturing method therefor

A soft polyurethane and foam technology, applied in the field of flexible polyurethane foam, can solve the problems of low density, inability to obtain soft polyurethane foam, and low NCO content, etc., and achieve the effect of good ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

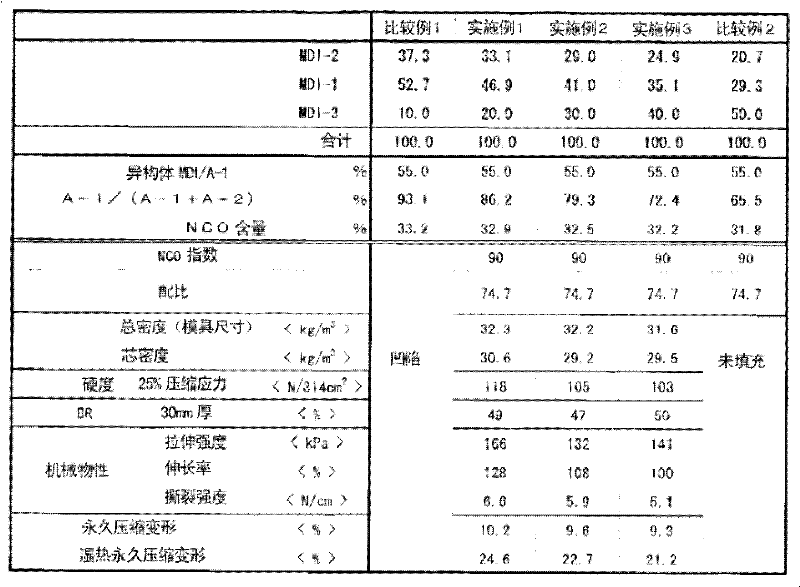

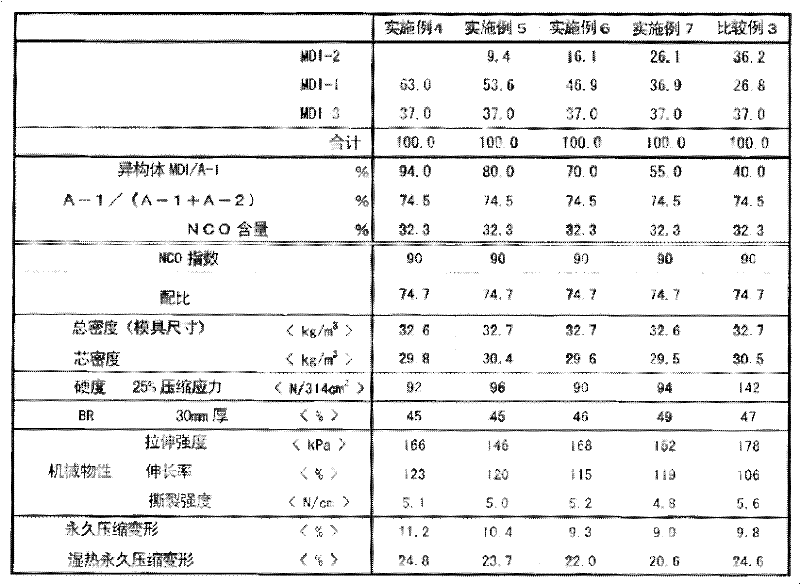

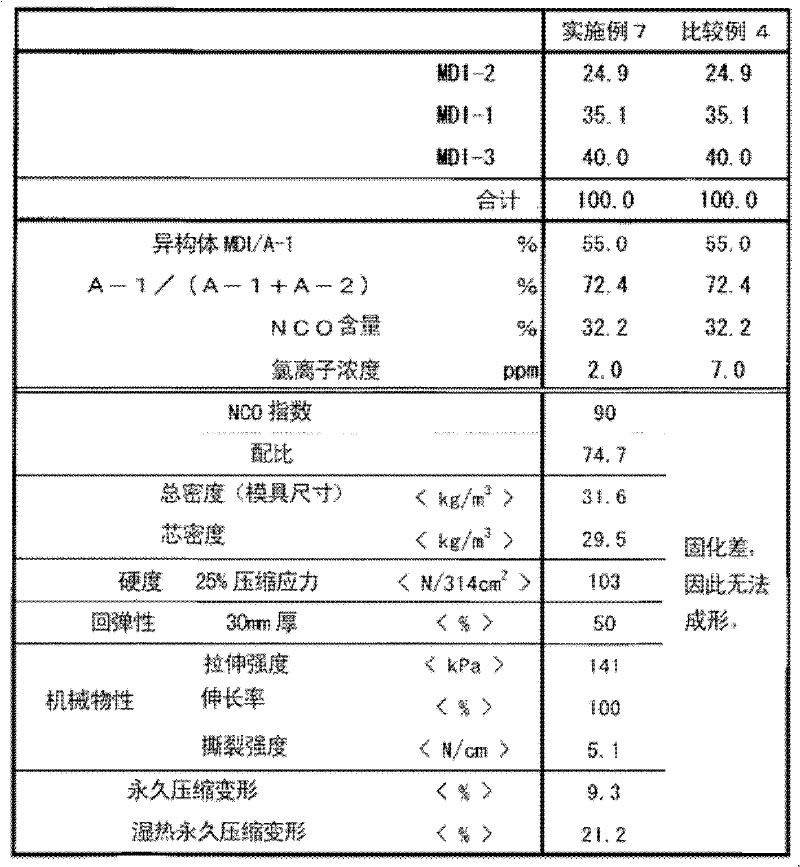

[0043] Hereinafter, although this invention is demonstrated more concretely based on an Example and a comparative example, this invention is not limited to a following example. In addition, unless otherwise specified, "parts" and "%" in the text are based on mass. In addition, raw materials used in Examples and Comparative Examples are as follows.

[0044] The raw materials used in the preparation of the organic polyisocyanate are as follows.

[0045] MDI-1: diphenylmethane diisocyanate containing 94% isomer MDI, 6% 4,4'-MDI, manufactured by Nippon Polyurethane Industry Co., Ltd.

[0046] MDI-2: Diphenylmethane diisocyanate containing 100% 4,4'-MDI, manufactured by Nippon Polyurethane Industry Co., Ltd.

[0047] MDI-3: MDI containing 31% 4,4'-MDI, 69% polymerized MDI, manufactured by Nippon Polyurethane Industry Co., Ltd.

[0048] The raw materials used in preparing the polyol premix are as follows.

[0049]

[0050] P-1: Polyoxyethylene polyoxypropylene polyol, nominal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com