Recycling device for residual fluid in fluid supply system/equipment and its use method

A fluid supply and fluid technology, applied in residential hot water supply systems, applications, piping systems, etc., can solve problems such as inability to recover branch pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

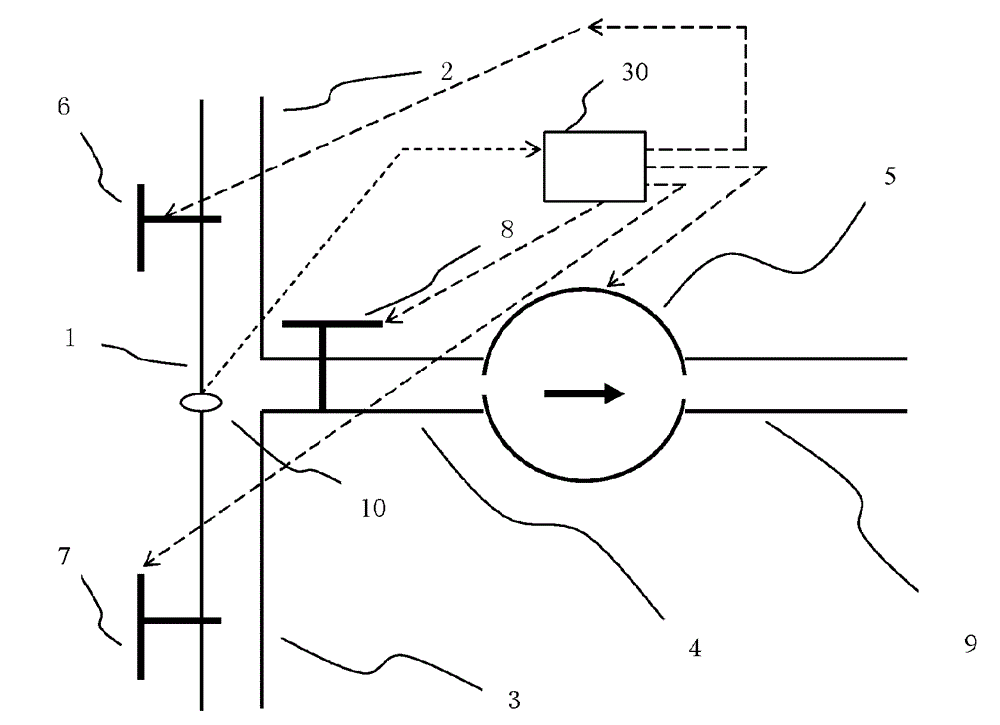

[0077] Example 1: A recycling device that uses a three-way pipe equipped with an electric two-way valve to control the flow of high-temperature (or low-temperature) liquid.

[0078] Such as figure 1 As shown, the recycling device includes a three-way structure 1 with a three-way pipe and an electric two-way valve. The three-way structure 1 connects the inlet pipe 2 with the high-temperature (or low-temperature) liquid supply system or the liquid inlet direction of the equipment. The pipes are connected, the outlet pipe 3 communicates with the pipe in the direction of the liquid supply system or the equipment, the outlet pipe 4 is connected to the liquid pump 5 and the outlet pipe 9 (the outlet pipe 9 can also be omitted), and the three-way structure 1 is provided with Inlet pipe electric two-way valve 6, outlet pipe electric two-way valve 7, extraction pipe electric two-way valve 8, a temperature sensor and a pressure sensor (not shown in the figure) are installed at position 10, ...

Embodiment 2

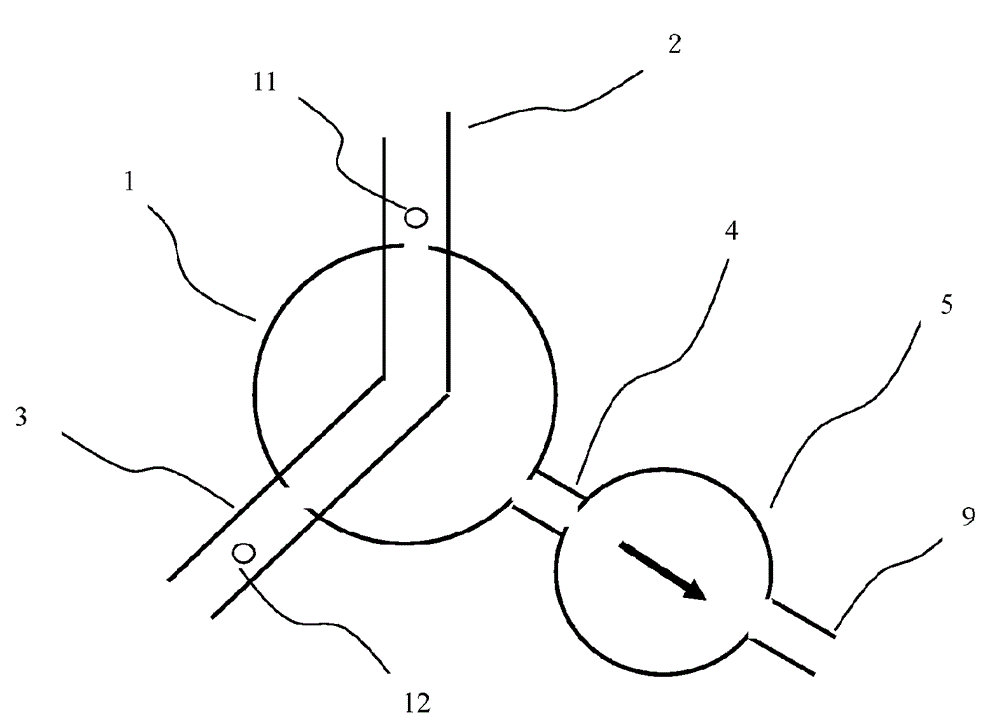

[0082] Embodiment 2: An electric three-way valve or an electric reversing valve is used to control the high temperature (or low temperature) liquid recycling device.

[0083] see figure 2 , Its working principle is the same as that of embodiment 1, except that the three-way structure 1 is an electric three-way valve or an electric reversing valve, which replaces the three-way pipe equipped with electric two-way valves 6, 7, and 8 of embodiment 1. Through the rotation of the electric three-way valve or the electric reversing valve, two of the inlet pipe 2, the outlet pipe 3, and the withdrawal pipe 4 are connected, and the other pipe is closed. Install a temperature sensor and a pressure sensor for sensing whether the liquid is flowing at position 11, install a pressure sensor for sensing whether the liquid is flowing and a conductivity sensor for sensing whether the liquid has been evacuated at position 12, when any pressure sensor measures When the liquid is flowing, the recycl...

Embodiment 3

[0084] Example 3: Automatic recovery of low CO 2 Recycling device for water content.

[0085] see figure 1 , The recycling device is usually installed in high CO 2 At the outlet of the water content supply system, the inlet pipe 2 of the recycling device and the high CO 2 High CO in water supply system 2 The water outlet of the content water is connected, the outlet pipe 3 is connected with the pipeline on the user side, and the extraction pipe 4 is connected to the liquid pump 5 and the outlet pipe 9. The three-way structure 1 is respectively provided with a normally open inlet solenoid valve 6 and an outlet solenoid valve 7 And the normally closed solenoid valve 8 for the extraction pipe, the flow direction of the liquid is controlled by opening and closing the solenoid valve. Install a CO at position 10 in the three-way pipe between the solenoid valves 6, 7, and 8 of the three-way structure 1. 2 Saturation sensor (or pH sensor), a water ripple switch and a conductivity sensor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com