Optical fiber type light reflection device and manufacturing method thereof

A manufacturing method and a technology of light reflection, which are applied in the direction of transmitting sensing components, light guides, optics, etc. by using optical devices, to achieve the effects of cost reduction, good stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

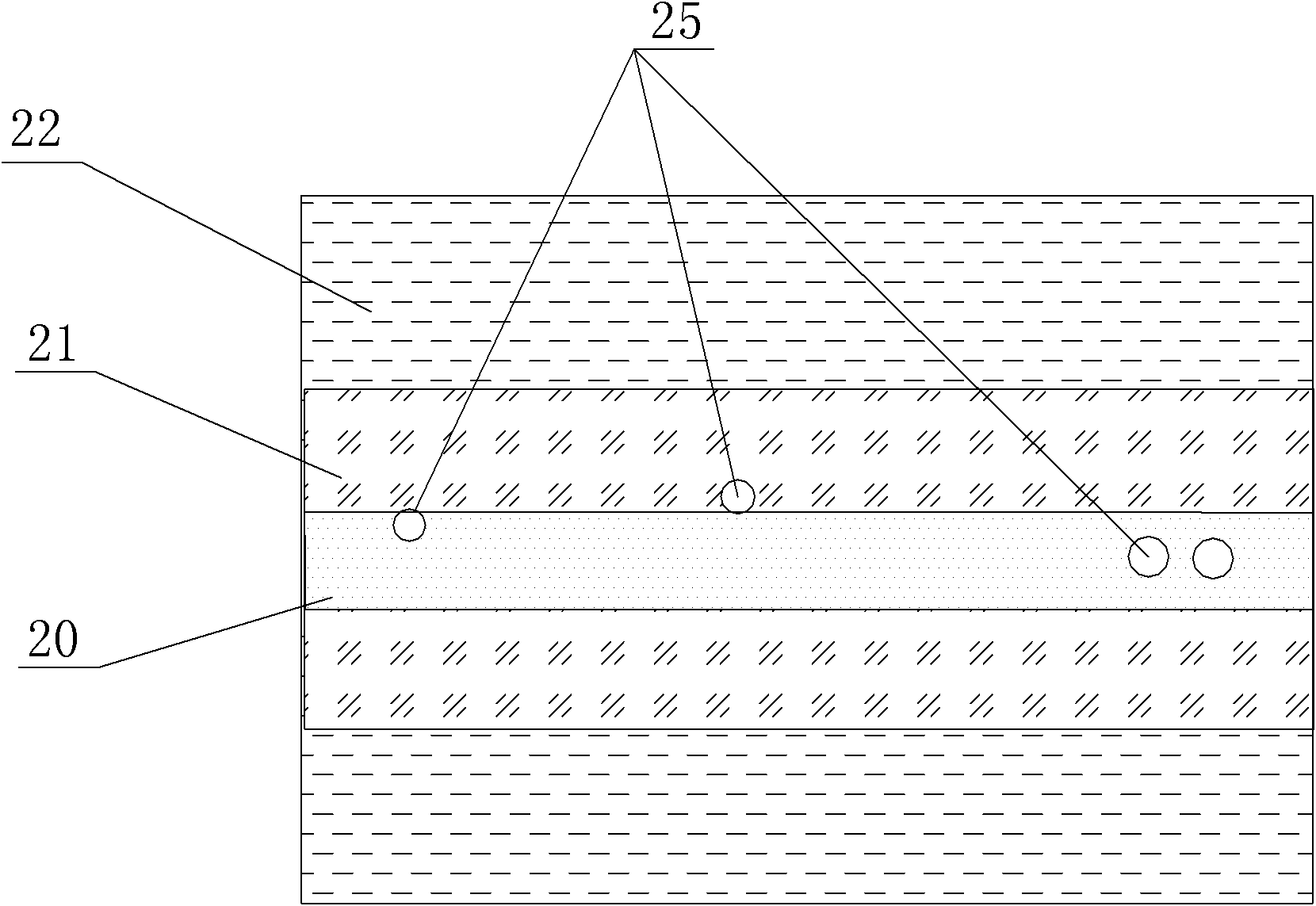

[0043] Such as figure 1 A kind of optical fiber type light reflection device shown, comprises optical fiber, is provided with optical fiber cladding 21 on the fiber core 20 of described optical fiber, is provided with coating layer 22 on described optical fiber cladding 21, in the fiber core of described optical fiber 20 or the fiber cladding 21 close to the fiber core 20 contains microbubbles 25 that can generate Fresnel reflected light signals for the light signals incident in the fiber. The microbubbles 25 are composed of two or more mutually independent microspaces. The microbubble 25 is a line hole penetrating through the optical fiber, or a line hole penetrating through the cladding of the optical fiber or the core of the optical fiber.

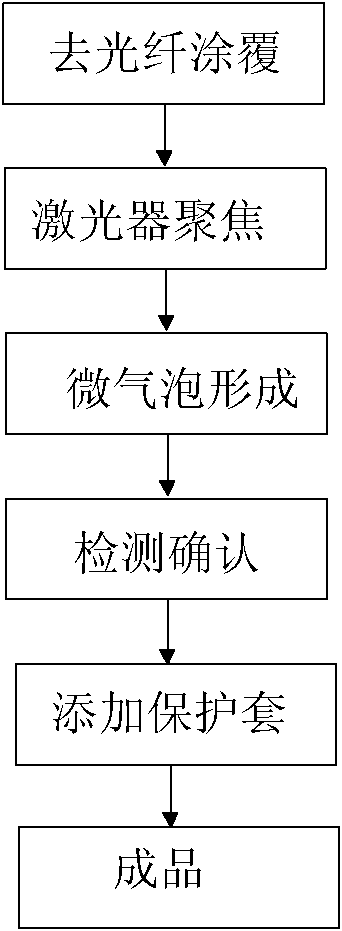

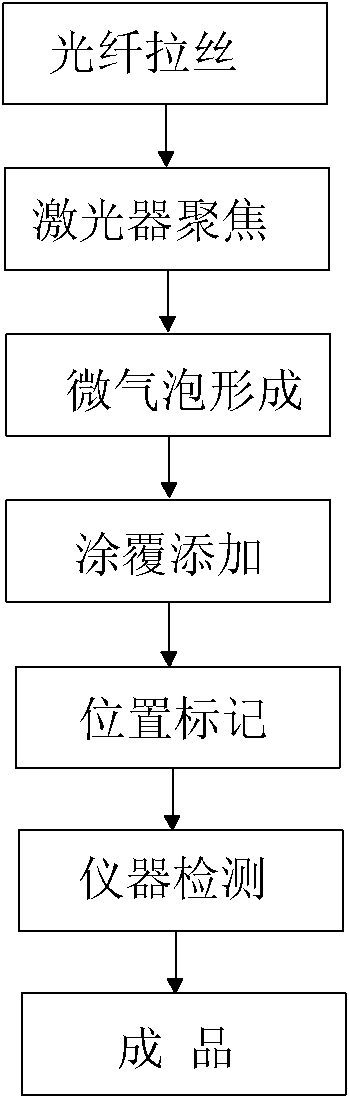

[0044] Such as figure 2 Shown, a kind of manufacturing method of optical fiber type light reflection device comprises the following steps:

[0045] Step 1, preparing the optical fiber for removing the polymer coating layer on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com