Method for processing salame rich in crude fiber

The technology of a ramy sausage and a processing method, which is applied in the field of food science, can solve the problems of a single flavor of the salad rice sausage and a short maturation time, and achieve the effects of enriching the consumer market, short maturation time and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

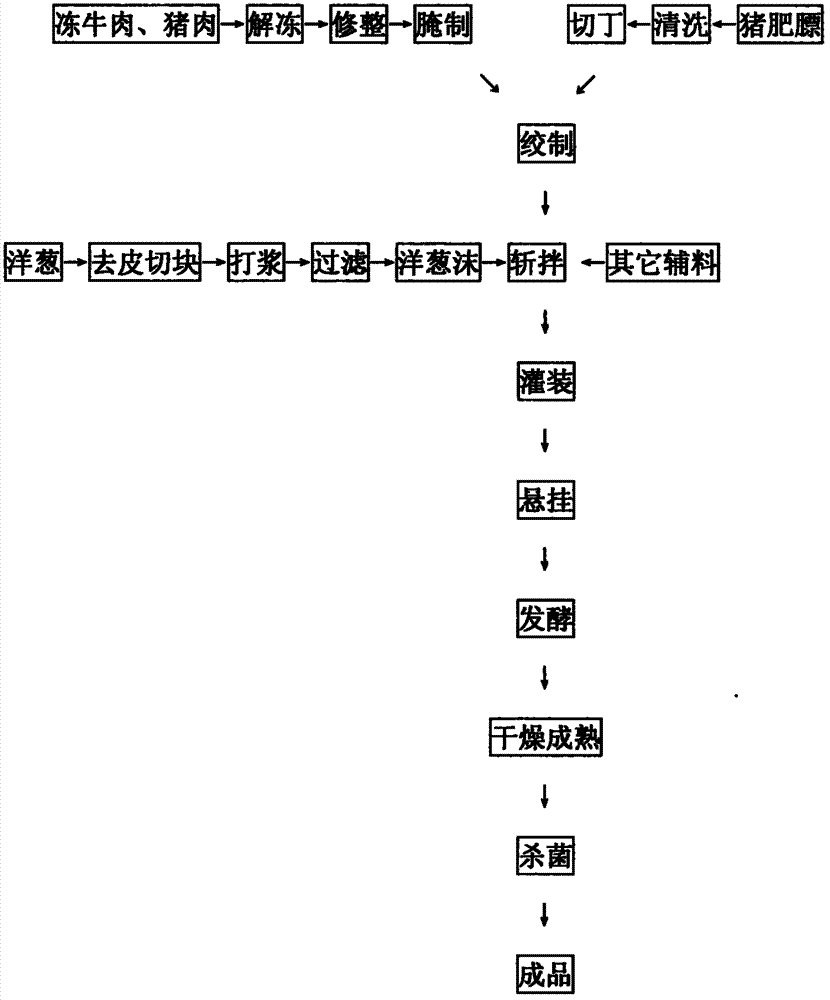

Image

Examples

Embodiment 1

[0037] The salami sausage rich in crude fiber adopts beef, pork, pig fat, minced onion, and seasoning as raw materials to make a kind of salami sausage rich in crude fiber. The weight parts of raw materials in the formula used are: beef 35%, Pork: 30%, pig fat: 10%, onion 20%, seasoning: 5%.

[0038] Producing crude fiber-rich salami follows the specific steps below:

[0039] (1) Raw meat pretreatment: Rinse frozen beef and pork with running cold water to thaw, then wash, remove bones and connective tissue, etc., cut into pieces for pickling; rinse pig fat with warm water to remove surface stains , diced.

[0040](2) Curing: prepare salting agent by raw meat weight: 1.5% of table salt, 0.015% of sodium nitrite, 0.5% of sodium ascorbate, and 0.5% of sodium iso-ascorbate. Spread the above-mentioned salting agent on the beef and pork, pay attention to spreading it as evenly as possible, and then put the beef and pork coated with the salting agent at 4°C for about 60 hours.

[...

Embodiment 2

[0050] The salami sausage rich in crude fiber adopts beef, pork, pig fat, minced onion, and seasoning as raw materials to make a kind of salami sausage rich in crude fiber. The weight parts of the raw materials in the formula used are: beef 30%, Pork: 40%, pig fat: 7%, onion 15%, seasoning: 8%.

[0051] Producing crude fiber-rich salami follows the specific steps below:

[0052] (1) Raw meat pretreatment: Rinse frozen beef and pork with running cold water to thaw, then wash, remove bones and connective tissue, etc., cut into pieces for pickling; rinse pig fat with warm water to remove surface stains , diced.

[0053] (2) Curing: prepare salting agent by raw meat weight: 1.5% of table salt, 0.012% of sodium nitrite, 0.5% of sodium ascorbate, and 0.5% of sodium iso-ascorbate. Spread the above-mentioned salting agent on the beef and pork, pay attention to spread as evenly as possible, and then put the beef and pork coated with the salting agent at 4°C for about 72 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com