Butterfly-shaped anti-depositing member

An anti-deposition and component technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of shortening the effective production cycle of the reaction tower, restricting the smooth production, increasing the load in the tower, etc. Operation cycle, conducive to safe and orderly operation, the effect of preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

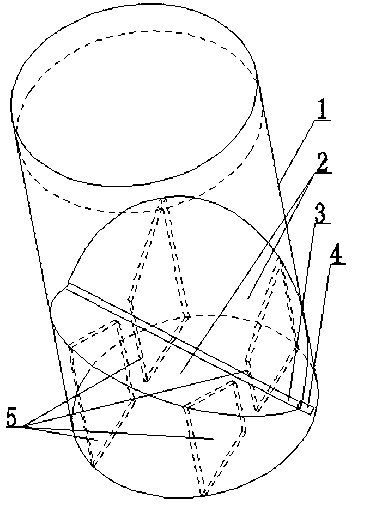

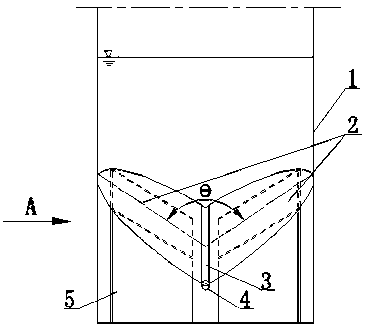

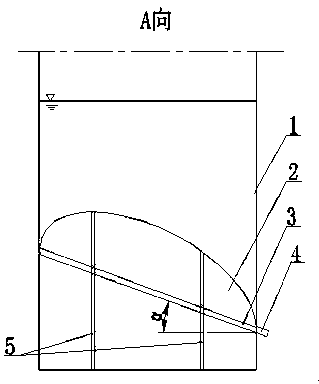

[0032] Example 2: Figure 4 , 5 , 6 represent the embodiment that the circular container contains the butterfly-shaped anti-sedimentation member of two pairs of wings, show in the figure, two diversion grooves 3 and 3-1 are obliquely placed in the circular container 1 oppositely to each other, the two The tops of the diversion grooves are connected, and the lower ports of the two oblique diversion grooves 3 and 3-1 are respectively connected with the two drain ports 4 and 4-1; the two sides of the diversion groove 3 are symmetrically connected to a pair of "V" The two sides of the shaped wing plate 2 and the diversion groove 3-1 are connected symmetrically to a pair of "V" shaped wing plates 2-1, and the upper edges of the two pairs of wing plates 2 and 2-1 are connected correspondingly to form an integrally connected Double butterfly member; the outer edge of the double butterfly member matches and seals the inner wall of the circular container 1 . The included angles betwe...

Embodiment 2

[0033] Example 3: Figure 7 , 8 , 9 represent the embodiment that the circular container contains four pairs of butterfly-shaped anti-sedimentation members of the wing plates. It is shown in the figure that the four diversion grooves 3, 3-1, 3-2, 3-3 are uniformly distributed in the radial direction and inclined Placed in the circular container 1, the tops of the four diversion grooves are connected, and the lower ports of the four oblique diversion grooves 3, 3-1, 3-2, 3-3 are respectively connected with the four drain ports 4, 4-1, 4-2 and 4-3 are connected; both sides of the diversion groove 3 are symmetrically connected to a pair of "V" shaped wings 2, and both sides of the diversion groove 3-1 are connected to a pair of "V" shaped wings symmetrically The two sides of the board 2-1 and the diversion groove 3-2 are connected symmetrically to a pair of "V" shaped wings 2-2, and the two sides of the diversion groove 3-3 are connected symmetrically to a pair of "V" shaped win...

Embodiment 3

[0034] Example 4: Figure 10 , 11 , 12 is the embodiment that contains the butterfly anti-deposition member of a pair of wing plate 2 in the square container 1, and its container 1 is a square, and the structural principle of the butterfly member that is arranged in the container is the same as Figure 1~3 The shown embodiment is the same, and the shape of the outer edge of a pair of wing plates 2 is matched with the inner wall of the square container 1 where it is located and sealed and connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com