Rubber sealing gasket for assembling of mill liners and installation method thereof

A rubber gasket and mill technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of difficult maintenance, expansion of bolt hole deformation, large maintenance costs, etc., to prolong the service life of equipment and improve economic benefits. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

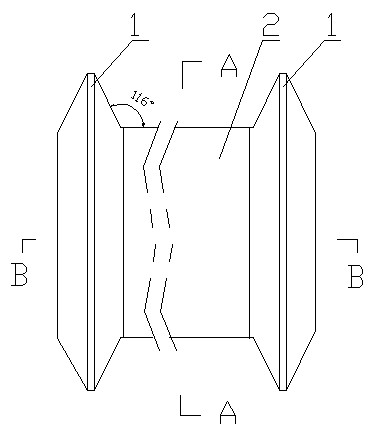

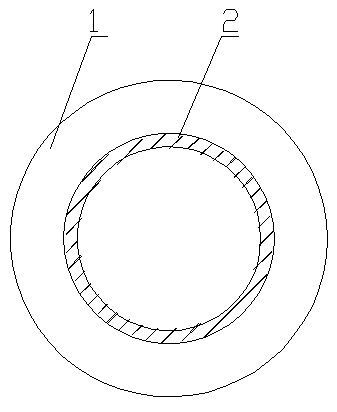

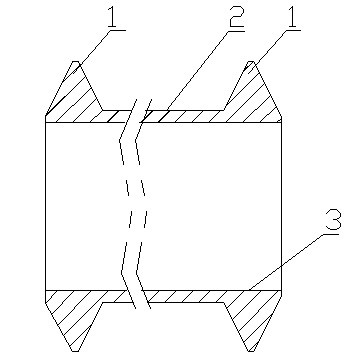

[0018] Example 1 Such as Figure 1-3 Shown: a rubber gasket for assembling the mill liner. The rubber gasket of the mill liner is a hollow cylindrical rubber gasket 4 with thick ends and a thin middle section. The cross-section of the two hollow thick ends 1 is Triangular shape, the thin hollow cylinder 2 in the middle section connects the two hollow thick ends 1 into one; the two hollow thick ends 1 share the same smooth inner cylindrical surface 3 with the inner cavity of the thin hollow cylinder 2 in the middle section, which is convenient Insert bolt 7.

Embodiment 2

[0019] Example 2 Such as Figure 4 Shown: an installation method for assembling the rubber gasket of the mill liner, including the mill liner 5 and the mill cylinder 6 that have been aligned and matched with the bolt installation holes processed:

[0020] [1] Lift the mill liner 5 piece by piece to the predetermined installation position in the mill cylinder 6, and align the bolt installation holes of the two; the bolt holes of the mill liner 5 and the mill cylinder 6 are aligned with the bolt holes 7, there is a matching gap for installing the hollow cylindrical rubber gasket 4, and put the soft hollow cylindrical rubber gasket 4 into the bolt installation holes aligned with the mill liner 5 and the mill barrel 6 holes and unfold smoothly.

[0021] [2] From the side of the mill liner 5, insert the bolt 7 into the installed hollow cylindrical rubber gasket 4, pass through the mill barrel 6, install and tighten the nut, the bolt head and the nut washer are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com