Automatic welding device

A technology of automatic welding and welding mechanism, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of overcoming adverse effects, reducing production costs, and getting rid of manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

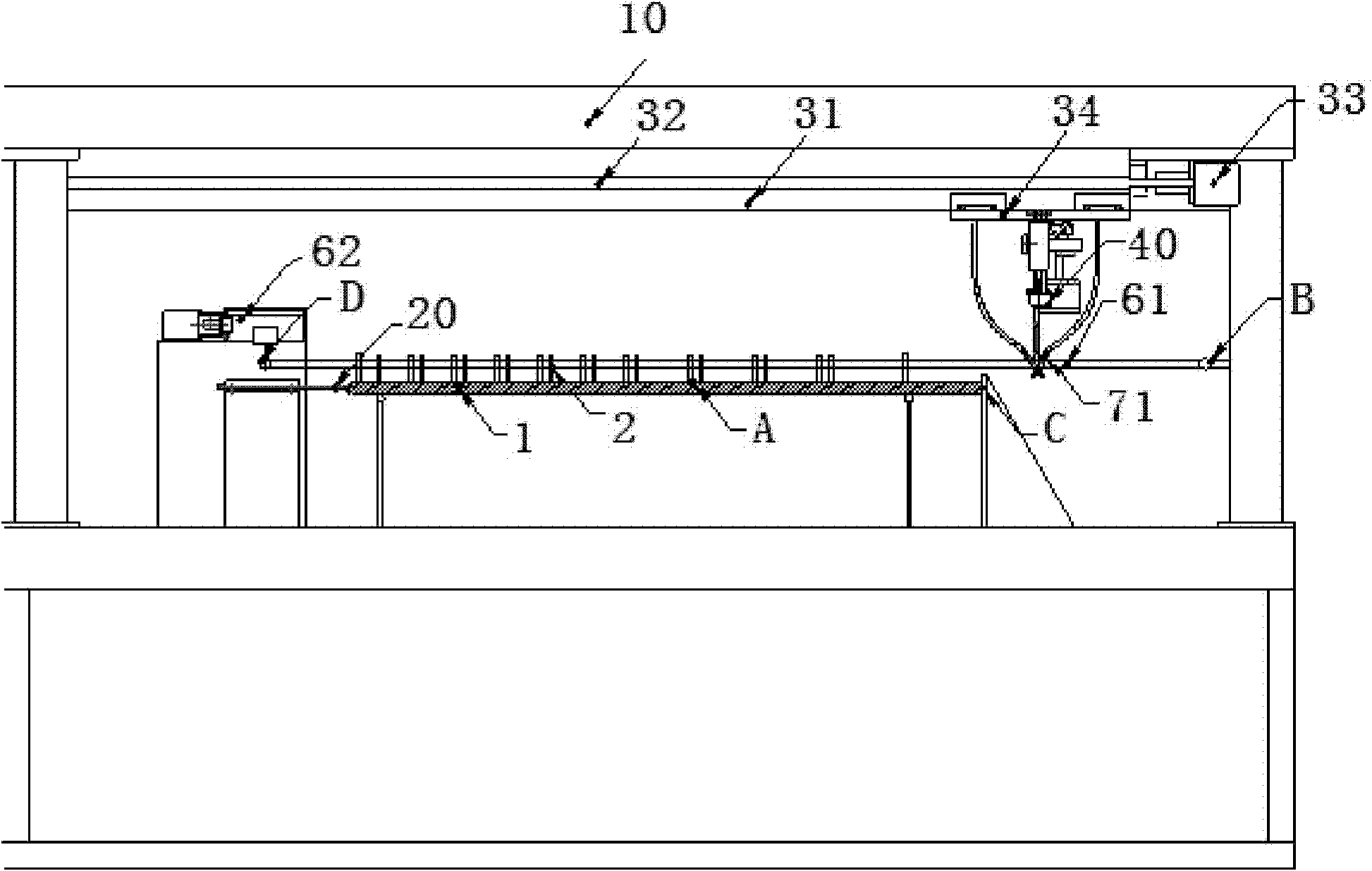

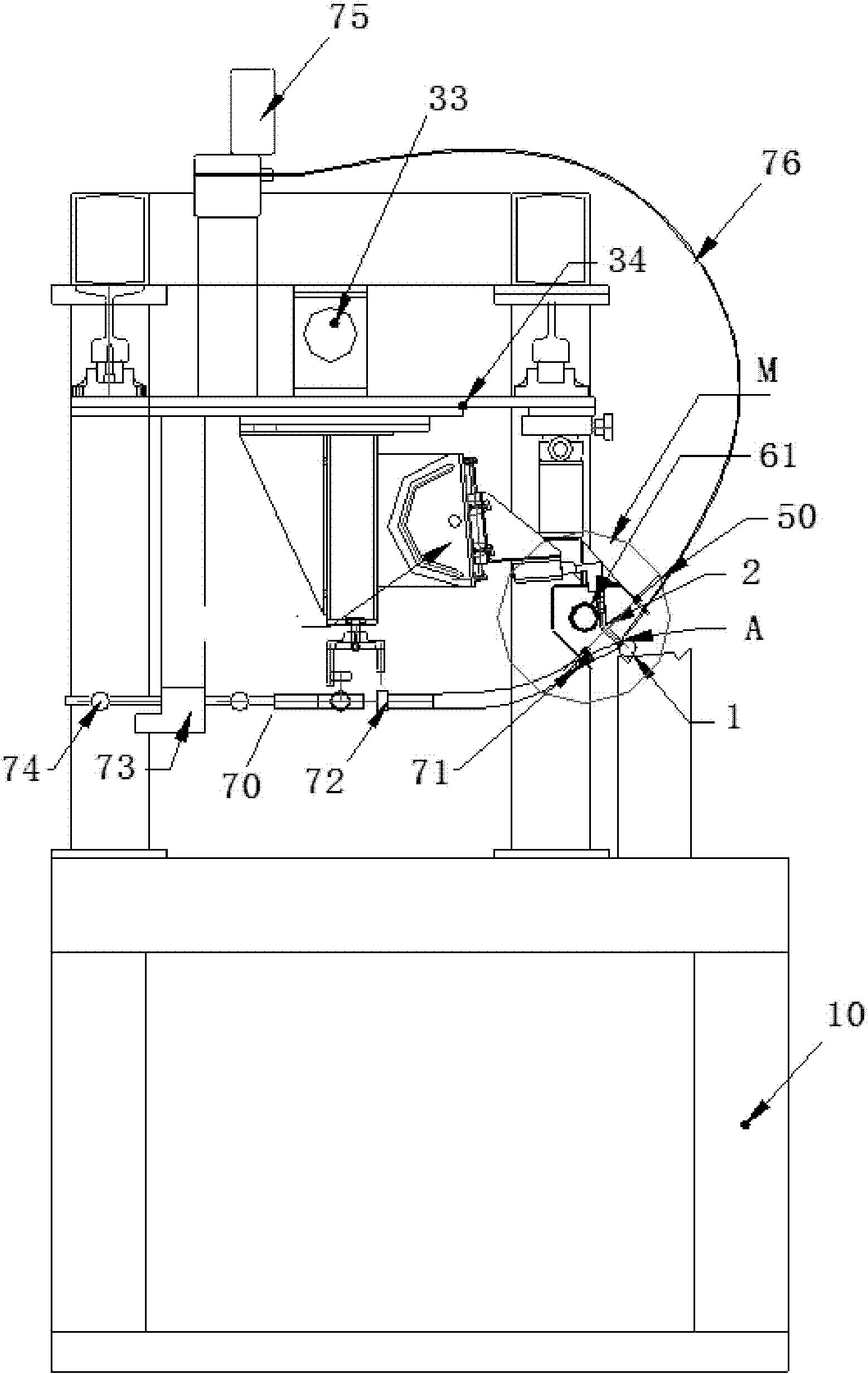

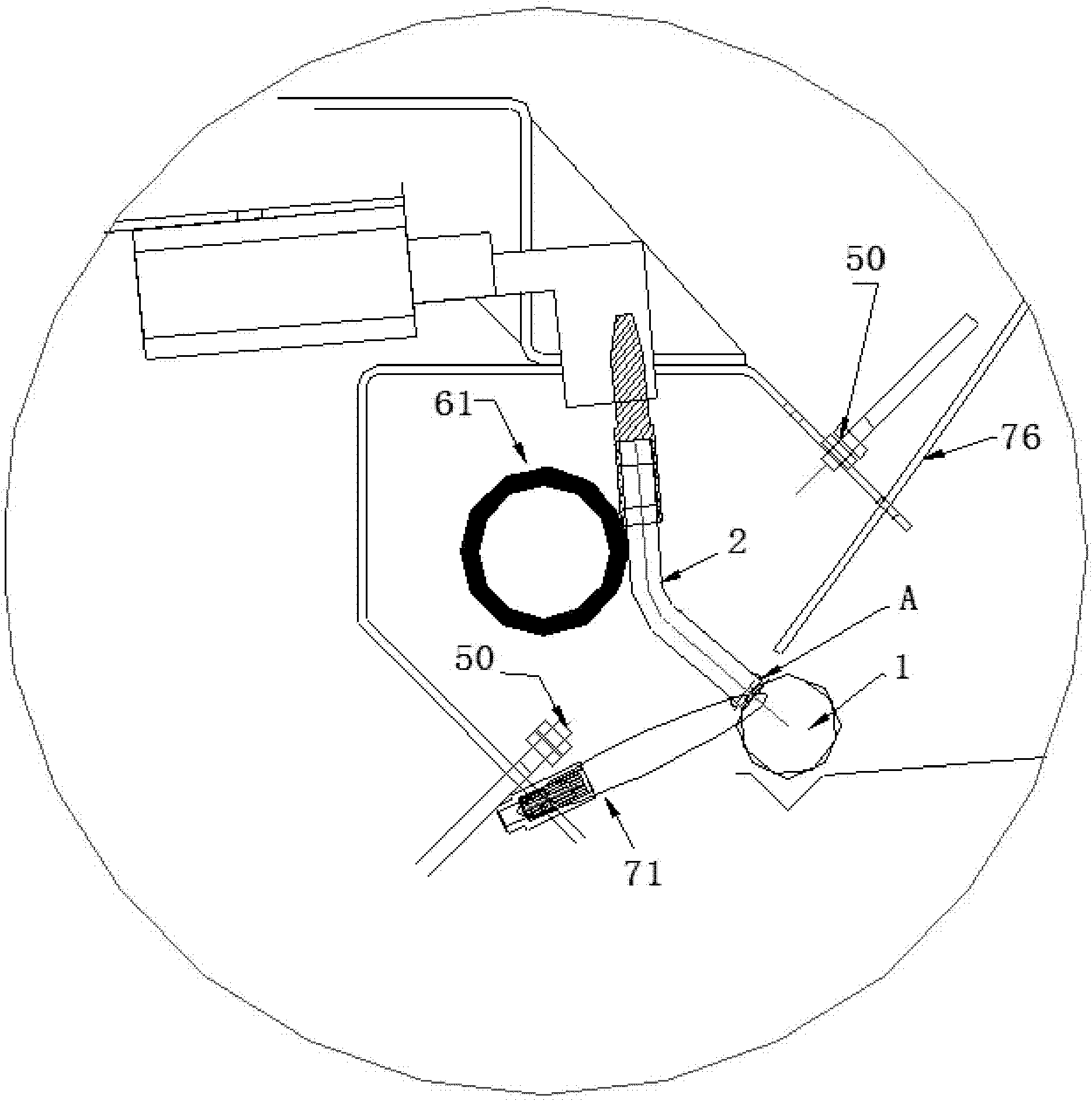

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0049] Design principle of the present invention is as follows:

[0050]Generally, the parts are assembled (pre-assembled) in cold state. When multiple parts are assembled on one main part, they need to be welded one by one. During the welding process, the temperature of the main part will gradually increase. , the thermal deformation will also gradually develop, the development of thermal deformation will make the assembly position shift, and the welding position will inevitably shift accordingly. When this change exceeds the welding allowable error, it will lead to welding failure or the position of the welded part exceeds Difference. For example, on a strip-shaped main part, it is required to extend the direction, install the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com