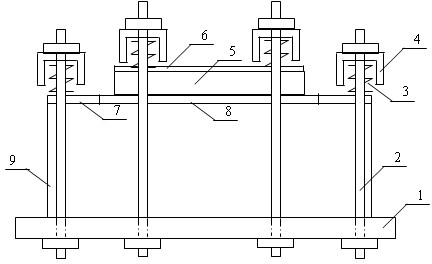

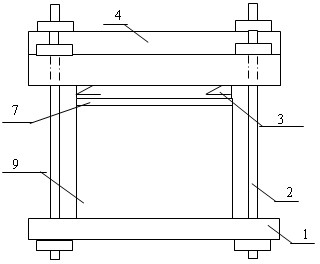

Combined type flexible clamp for vacuum brazing of core body of plate-fin type aluminum heat exchanger

A plate-fin heat exchanger and flexible fixture technology, which is applied in the field of aluminum alloy welding, can solve the problems of heat exchanger core leakage brazing seam performance, brazing seam performance can not meet the requirements, heat exchanger core leakage and other problems , to achieve the effect of low cost, long service life and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

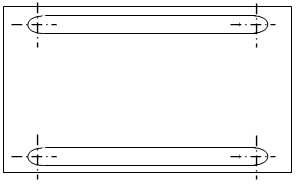

Examples

Embodiment 1

[0051] The core size of a certain type of aluminum plate-fin heat exchanger with two heat exchange channels is (length × width × height): 830 × 150 × 973mm. The material of the guard plate is 3003 aluminum alloy plate, the size is (length×width×thickness): 830×150×4 mm; the material of the fin is 3003 aluminum alloy plate, the thickness is 0.2 mm, zigzag fin; the material of the partition is 434 Aluminum alloy cladding plate, the size is (length×width×thickness): 830×150×1.2mm; the seal material is 3003 aluminum alloy, cubic seal, and the size of seal 1 is (length×width×height): 150×15× 9.5mm, the size of the seal 2 is (length×width×height): 830×3×2.5mm; the brazing material brazed between the guard plate, the fin and the seal is 0.1mm thick 4004 brazing filler metal, the size is ( Length x width): 830 x 150mm.

[0052] The relevant parameters of the combined flexible fixture are as follows:

[0053] A bottom plate is made of 1Cr18Ni9Ti stainless steel plate with a thickness...

Embodiment 2

[0070] The core size of a certain type of aluminum plate-fin heat exchanger with two heat exchange channels is (length × width × height): 470 × 210 × 327mm. The material of the guard plate is 3003 aluminum alloy plate, the size is (length×width×thickness): 470×210×6 mm; the material of the fin is 3003 aluminum alloy plate, the thickness is 0.6 mm, straight fin; the material of the separator is 434 aluminum alloy cladding plate, the size is (length×width×thickness): 470×210×1.2mm; the seal material is 3003 aluminum alloy, cubic seal, and the size of seal 1 is (length×width×height): 210×12 ×9.5mm, the size of the seal 2 is (length×width×height): 470×12×3mm; the brazing material brazed between the guard plate, the fin and the seal is 0.1mm thick 4004 brazing filler metal, the size is ( Length x width): 470 x 210 mm.

[0071] The relevant parameters of the combined flexible fixture are as follows:

[0072] Base plate, spring and groove type spring pressing plate are the same as ...

Embodiment 3

[0082] The core size of a certain type of aluminum plate-fin heat exchanger with two heat exchange channels is (length × width × height): 488 × 150 × 1440mm. The material of the guard plate is 3003 aluminum alloy plate, the size is (length×width×thickness): 488×150×8 mm; the material of the fin is 3003 aluminum alloy plate, the thickness is 0.3 mm, zigzag fin; the material of the partition is 434 Aluminum alloy cladding plate, size (length×width×thickness): 488×150×1.2mm; seal material is 3003 aluminum alloy, cubic seal, and the size of seal 1 is (length×width×height): 150×8× 3mm, the size of the seal 2 is (length×width×height): 488×2.5×3mm; the brazing material brazed between the guard plate and the fin and the seal is 0.1mm thick 4004 brazing filler metal sheet, the size is (length× width): 488×150mm.

[0083] The relevant parameters of the combined flexible fixture are as follows:

[0084] Base plate, spring and groove type spring pressing plate are the same as embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com