Manufacture method of anti-deformation water beam in sintering system

A production method and anti-deformation technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of long production cycle and high cost, and achieve the effect of reducing production cost, eliminating thermal stress and shortening processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0025] A method for manufacturing an anti-deformation water beam in a sintering system, the method comprising the steps of:

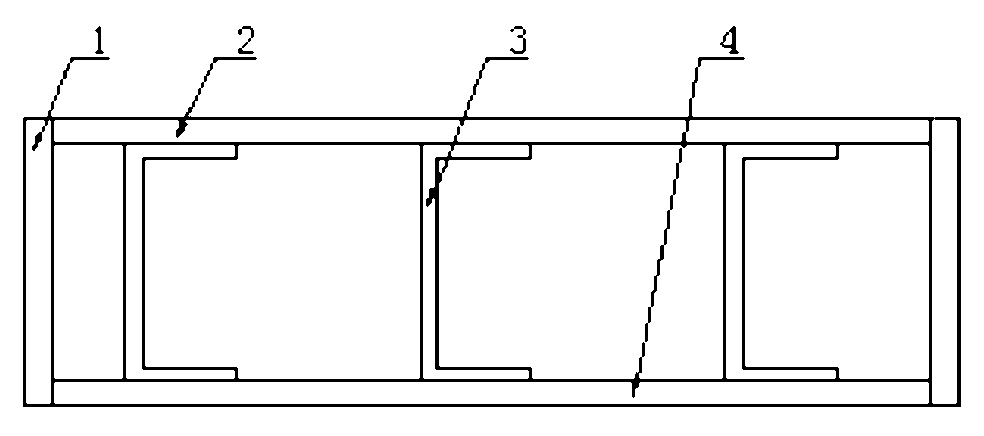

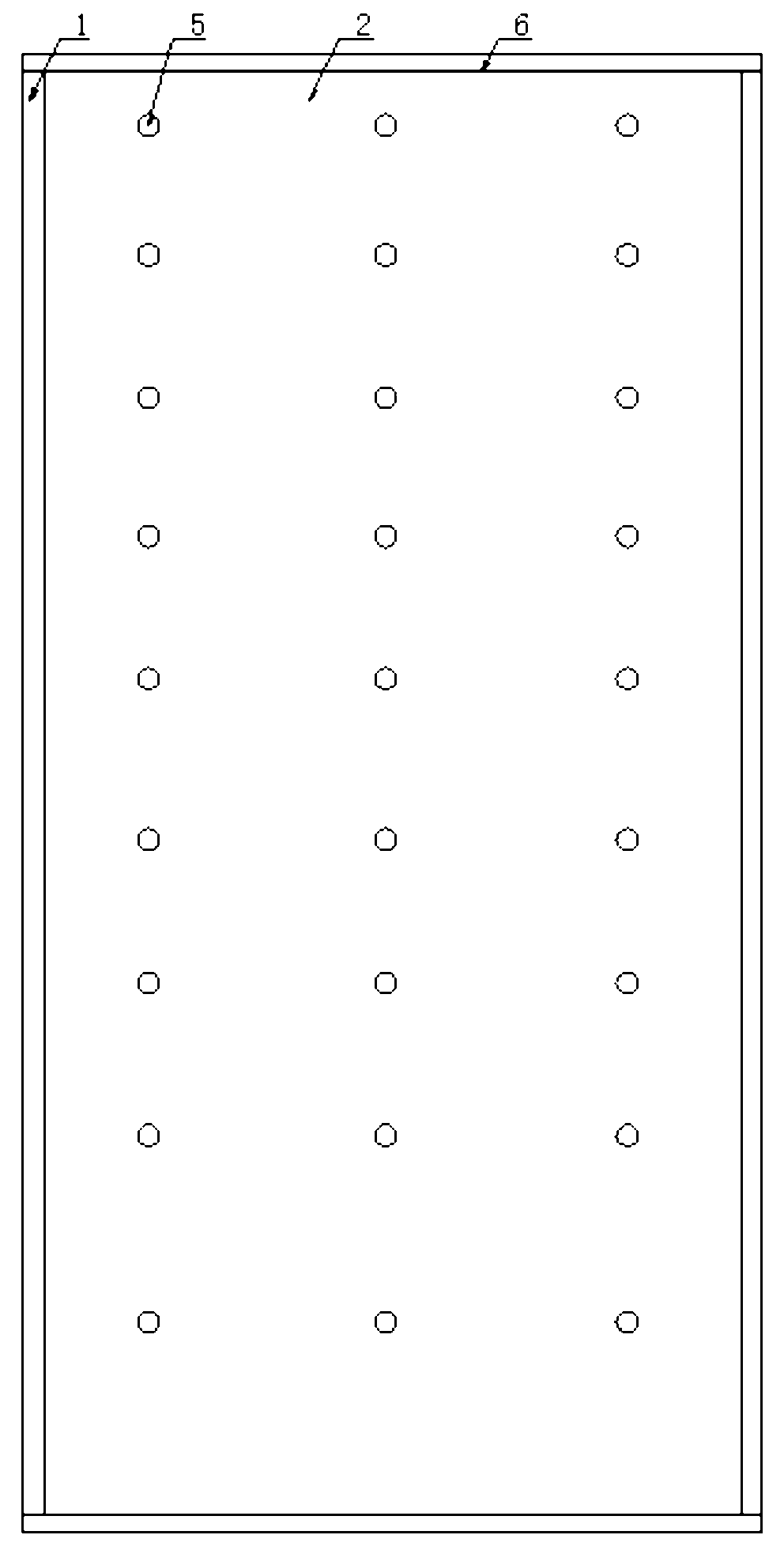

[0026] (1) For the upper cover plate 2, lower cover plate 4, two side plates 1 and two end plates 6 that make up the water beam, according to the geometric dimensions required by the drawing, add 4mm of welding shrinkage allowance in the length and width directions ;

[0027] (2) Use a flatbed machine to level the cut upper cover plate, lower cover plate and two end side plates multiple times; the leveling is mainly to eliminate the rolling stress of the plate and the thermal stress generated after being heated during cutting;

[0028] (3) Straighten the channel steel 3 with a jack or a flame; the channel steel is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com