Internal combustion electric bolt spanner

A technology of internal combustion electric bolts and wrenches, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficulty in meeting the requirements of short-term skylight operations, high energy consumption and low precision in vertical bolt and nut operations, and achieve light weight , large size and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

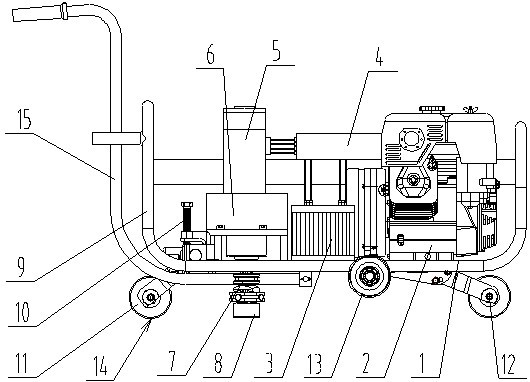

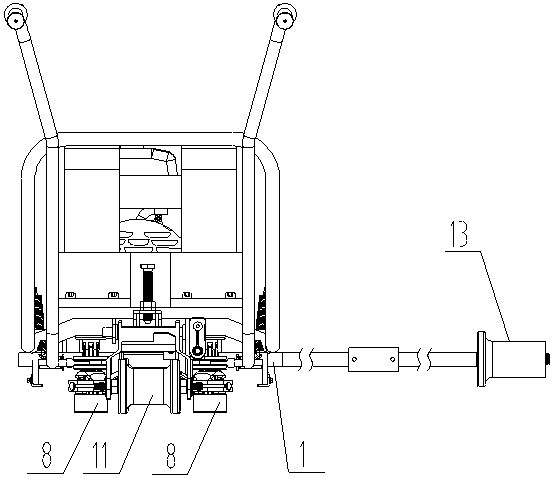

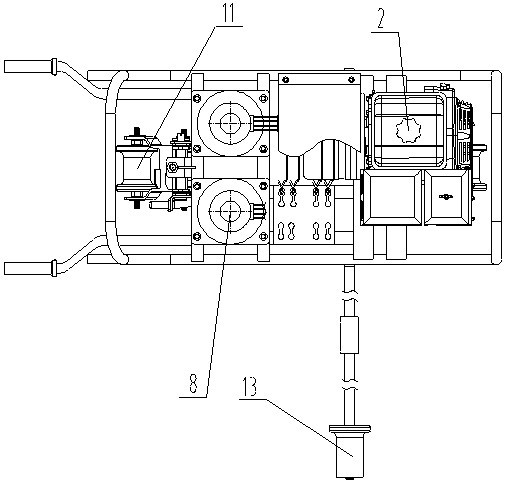

[0028] Below in conjunction with accompanying drawing, the structure of internal combustion electric bolt wrench of the present invention is described in detail:

[0029] Such as figure 1 , figure 2 , image 3 Shown: the internal combustion electric bolt wrench of the present invention comprises a frame 1 and a generator 2 installed on the frame 1, a lithium-ion battery pack 3, a current controller 4, a motor 5, a reducer 6, a quill 7, a sleeve The cylinder 8, as well as the sleeve operating mechanism 9 and the height adjustment mechanism 10, are provided with a running mechanism 14 under the frame 1, and the running mechanism 14 cooperates with the railway track to walk on the track during work; figure 1 , 2 , the walking mechanism 14 shown in 3, comprises front traveling wheel 11, rear traveling wheel 12 and auxiliary supporting axle 13, and front traveling wheel 11, rear traveling wheel 12 are roughly arranged in a straight line front and back, internal combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com