Method for preparing high-viscosity chitosan by using chitin

A chitin and chitosan technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of cumbersome repeated sampling and detection, difficult temperature control, high energy consumption, etc., to shorten the reaction time, shorten the production cycle, energy low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take a certain quality of chitin, soak it in tap water at 60°C for 6 hours, wash it at 60°C by ultrasonic method for 1 hour, then dry it at 105°C for 3 hours, then crush it to 60-80 mesh and repeat the above washing and drying steps. Take 10g of dried powder and add 120g of 30% concentration NaOH solution, so that the mass ratio of NaOH solution to chitin is 12:1, stir at 40°C for 10min, put it into an 800W, 2450MHz microwave reactor and heat for 5min to take it out, and the temperature of the mixture is now 90°C, filter and rinse with 60°C water until the pH value is 7.2-7.5, add the product to 50% NaOH solution, make the mass ratio of NaOH solution to chitin is 12:1, mix well and heat to 90°C, keep the temperature and stir After 50 minutes of reaction, the product was washed with water at 60°C until the pH value was 7.2-7.5, and dried at 105°C for 3 hours to obtain high-viscosity chitosan powder.

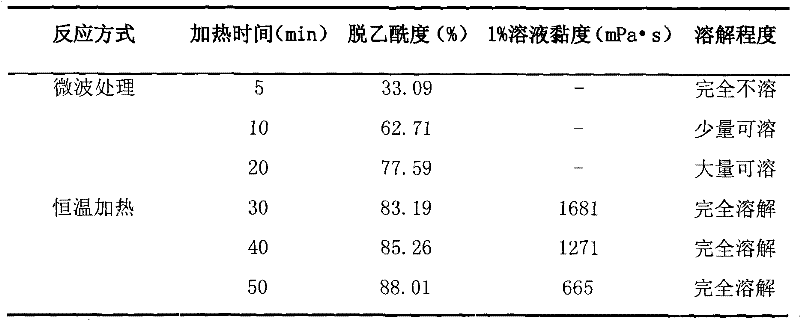

[0030] Table 1 shows the changes of deacetylation degree and viscosity...

Embodiment 2

[0044] Take a certain quality of chitin, soak it in tap water at 60°C for 6 hours, wash it at 60°C using ultrasonic method for 1 hour, and then dry it at 105°C for 3 hours, then crush it to 60-80 mesh and repeat the above washing and drying steps. Take 10g of dried powder and add 100g of 30% concentration NaOH solution, so that the mass ratio of NaOH solution to chitin is 10:1, stir at 40°C for 10min, put it into a 800W, 2450MHz microwave reactor and heat for 3min to take it out, at this time the temperature of the mixture is 78°C, filter and rinse with 60°C water until the pH value is 7.2-7.5, add the product to 50% NaOH solution, make the mass ratio of NaOH solution to chitin 10:1, mix well and heat to 90°C, keep the temperature and stir After 50 minutes of reaction, the product was washed with water at 60°C to pH 7.2-7.5 and dried at 105°C for 3 hours to obtain high-viscosity chitosan powder.

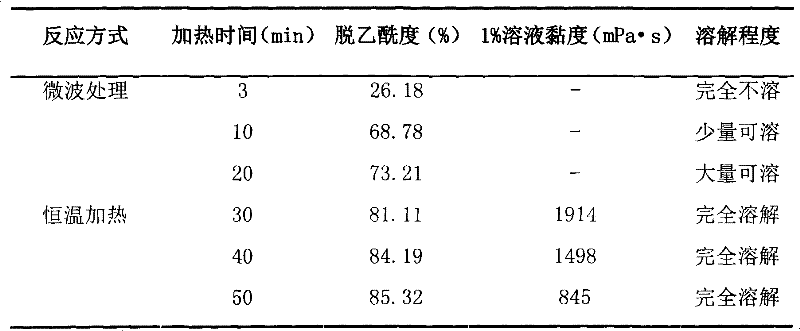

[0045] Table 3 shows the changes of deacetylation degree and viscosity every 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com