Concentrated alkaline concentration online measurement and control system

A detection and control system, concentrated alkali technology, applied in textiles and papermaking, textile processing machine accessories, textile material processing, etc., can solve problems such as low measurement accuracy, impact on the environment, and inability to continuously measure concentrated alkali concentration in real time, and meet the requirements of Mercerizing requirements, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

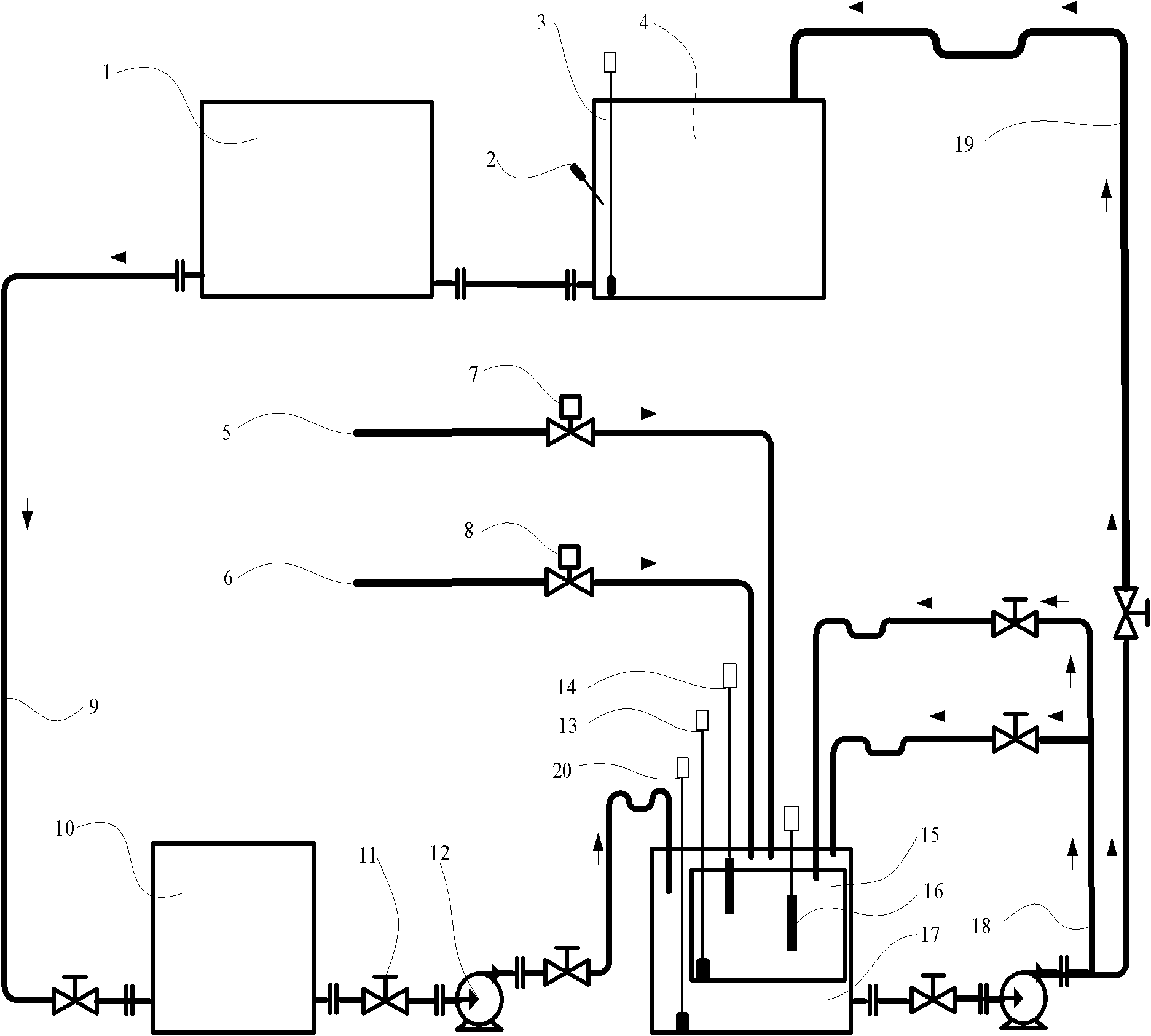

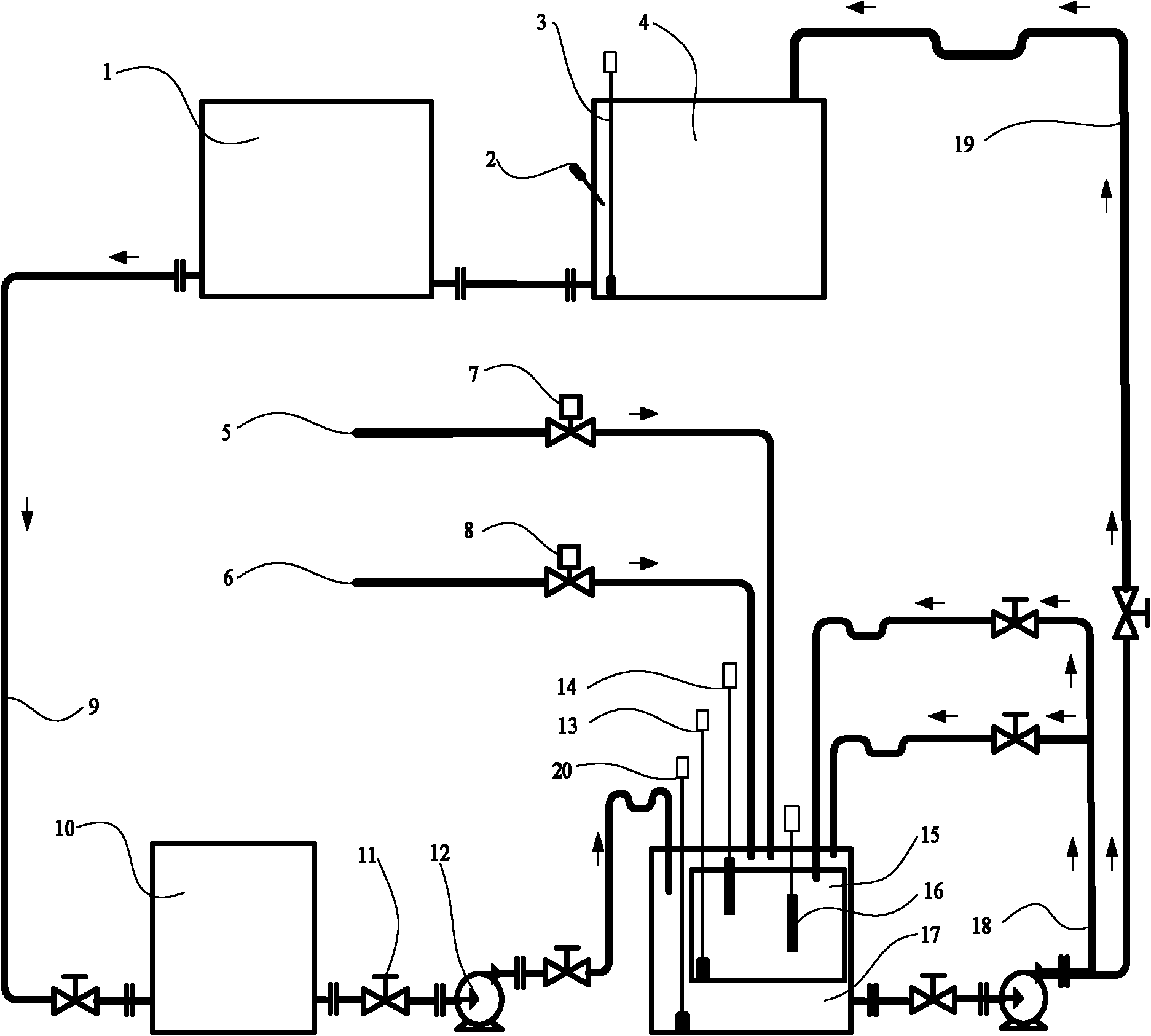

[0016] A kind of strong alkali concentration on-line detection control system of the present invention as shown in the accompanying drawing, it comprises (a) at least two immersion tanks 1,4, communicate through connecting pipeline between these at least two immersion tanks, in one of them A temperature detection device 2 and a first liquid level detection device 3 are installed in the dipping tank; (b) a filter box 10 on which a second liquid level detection device is installed, and the inlet of the filter box passes through a first manual valve on which The light alkali reclaiming inlet pipeline 9 is communicated with the outlet of 2# dipping tank 1; (c) an alkali distribution tank 17 in which the third liquid level detection device 20 is installed, and the inlet of the alkali distribution tank is equipped with The light alkali recovery out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com