Exhausting brake valve for automobile and automobile

A technology of exhaust brake valve and single-acting cylinder, which is applied in the direction of engine control, machine/engine, fluid pressure actuation device, etc., and can solve the problem that the constant pressure spring and piston are easy to corrode and age, and cannot meet the constant pressure function and stroke Problems such as poor control can be avoided to prevent the valve plate from being closed, high braking transmission efficiency, and easy stroke control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

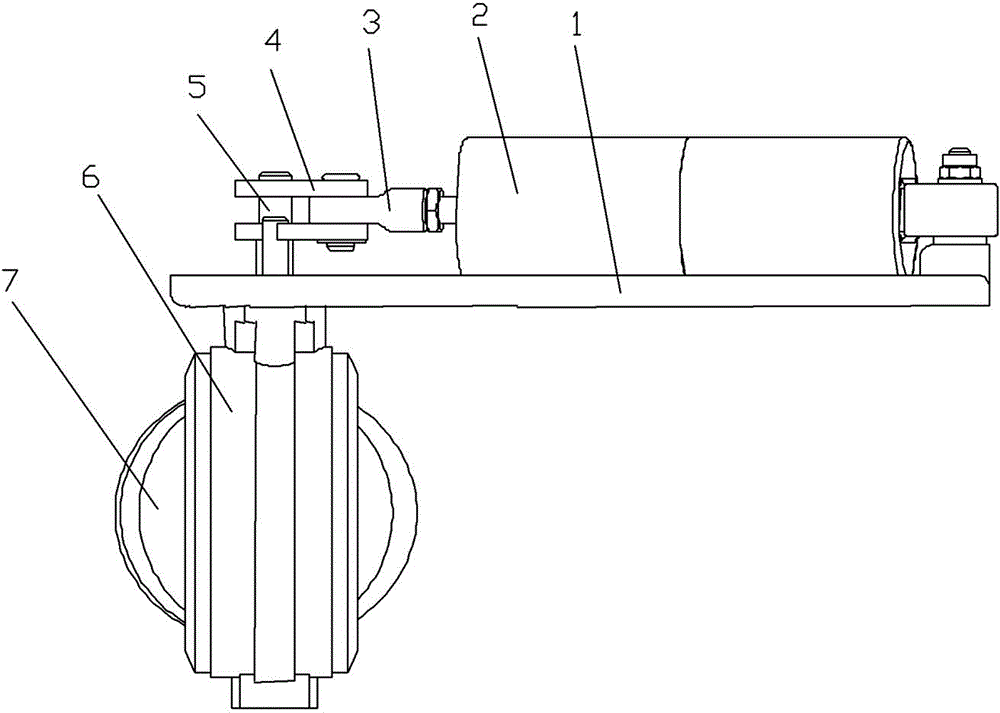

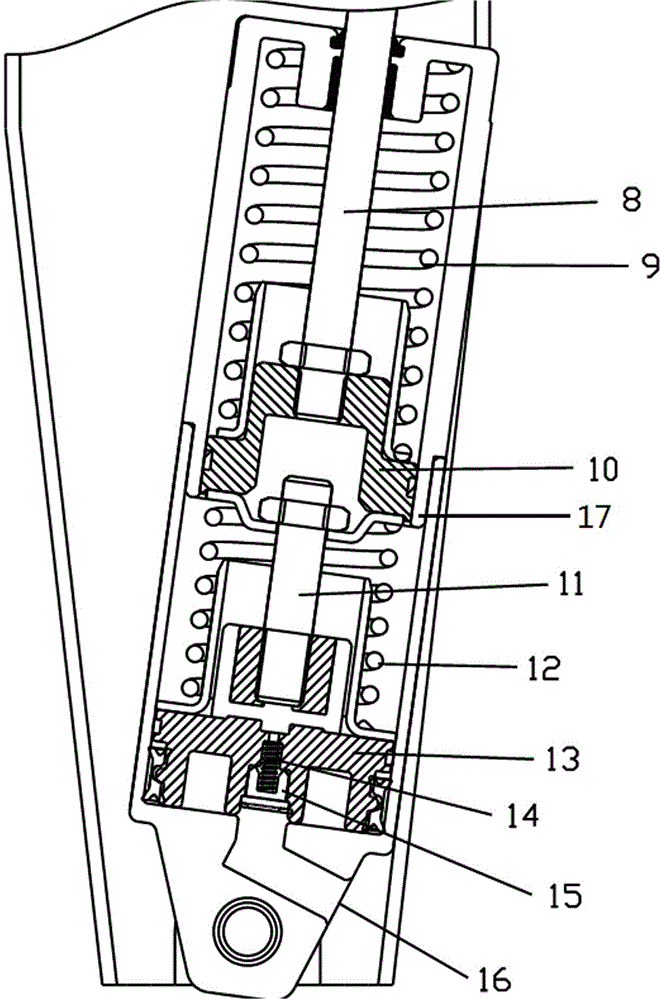

[0028] Such as figure 1 and 2 As shown, the push rod 8 at the output end of the cylinder 2 is connected to the connecting fork 3, one end of the articulated rocker arm 4 of the connecting fork 3 is rotatable, the other end of the rocker arm 4 is fixedly connected to the rotating shaft 5, and the rotating shaft 5 runs through the valve body 6 and the valve plate 7. The valve plate 7 can rotate around the rotating shaft 5 in the valve body 6. The rotating shaft 5 is offset by a certain distance relative to the center line of the valve plate 7. The bracket plate 1 and the valve body 6 have an integral structure, or the bracket plate 1 is fixed on the valve body. On the body 6, the cylinder 2 is fixed on the support plate 1, and the rotating shaft 5 deviates from the extension line of the output end push rod 8 of the cylinder 2.

[0029] The end of the cylinder 2 away from the push rod 8 has an air inlet 16. The cylinder 2 is composed of a plunger cylinder and a single-acting cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com