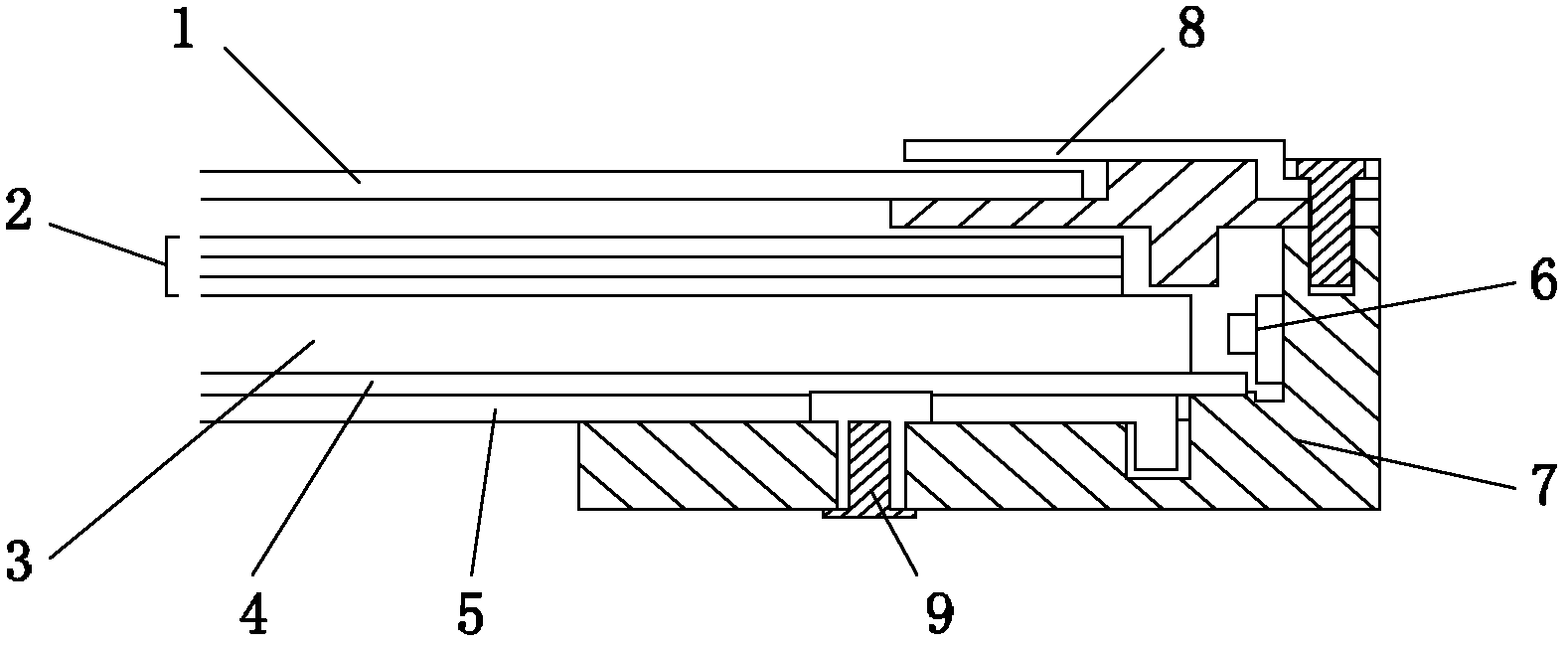

Backlight module and liquid crystal display device

A technology of backlight module and light guide plate, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as cracking of light guide plate 3, achieve cheap materials, avoid shaking and impact, and avoid extrusion damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

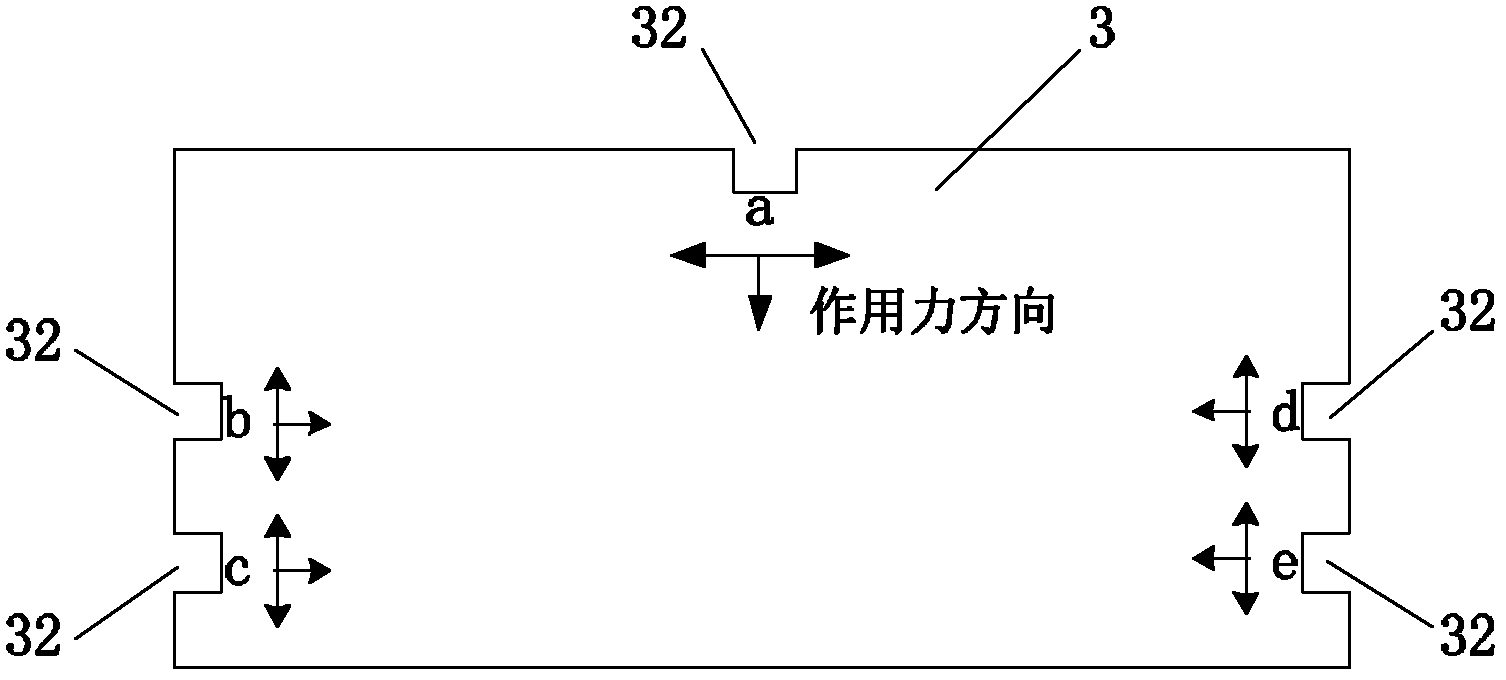

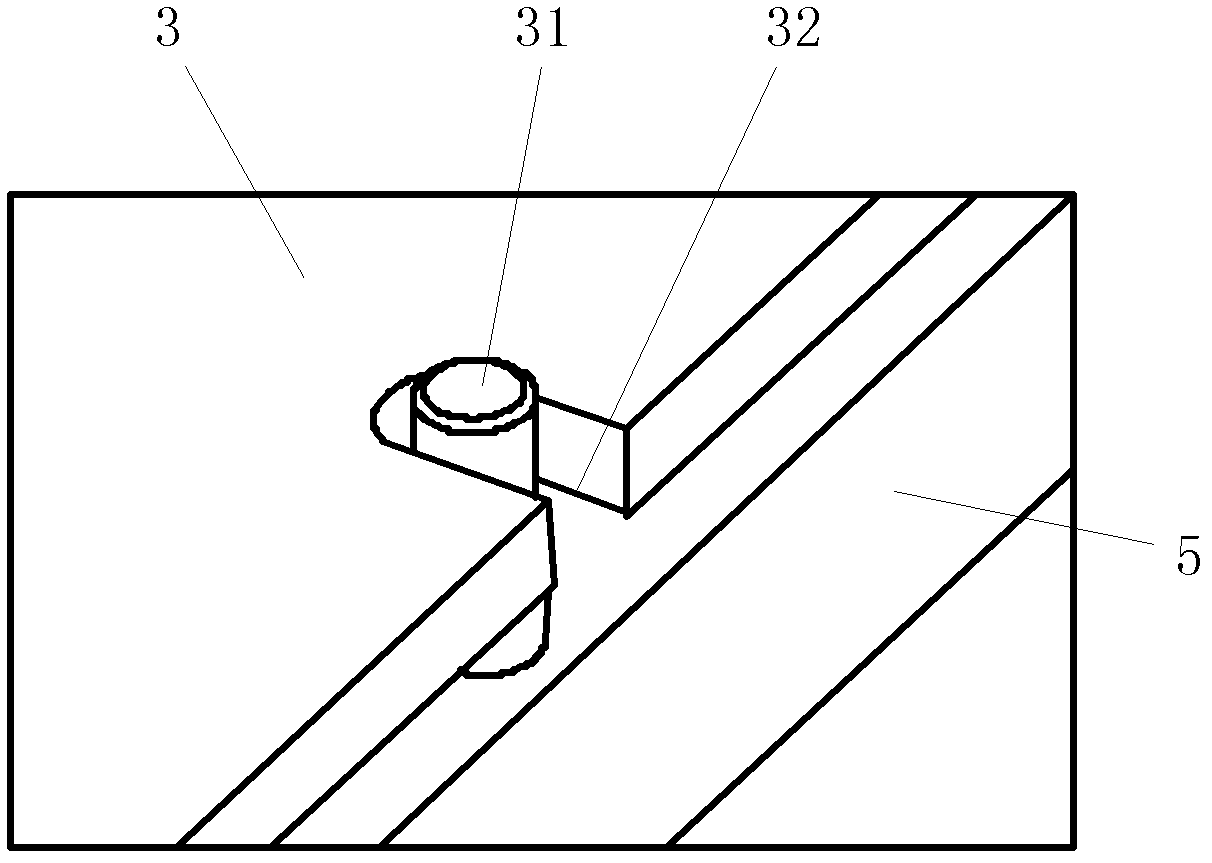

[0036] Such as Figure 9 Shown is the third embodiment of the present invention, and the difference from the first embodiment is that the rivet 31 is tightly wrapped by the buffer structure 33, and there is no gap on the contact surface between the two, so that the rivet 31 can be avoided relative to the The light guide plate 3 vibrates over a large distance, thereby reducing the force of the collision.

[0037]In several embodiments of the present invention, the material of the buffer structure is preferably a material with good wear resistance, so that the buffer structure can be guaranteed not to be worn during vibration, thereby ensuring its reliability as a buffer structure. Generally speaking, silica gel or rubber or foamed plastics are better cushioning materials, which have good elasticity, strong wear resistance, and are cheap.

[0038] The cushioning structure can be manufactured into a standard part through a mold, which can be mass-produced and has good versatilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com