Method for eliminating vibration noise in shaft torsional deformation test

A deformation test and vibration elimination technology, which is applied in the measurement field to achieve the effects of improving measurement accuracy, simple structure and eliminating noise interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

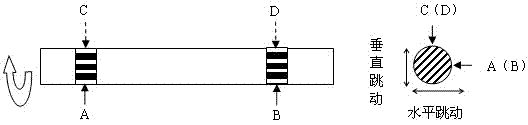

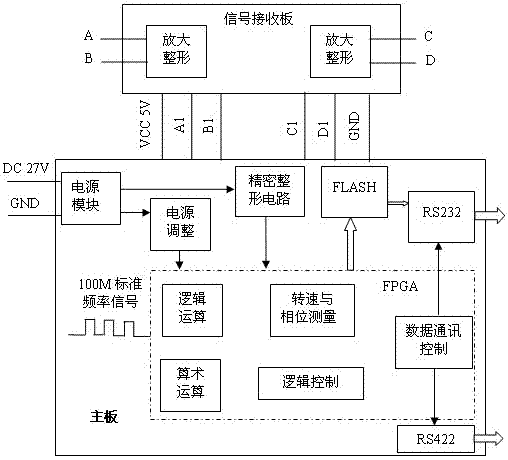

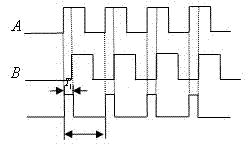

[0016] like figure 1 As shown, reflective gratings (that is, strips reflecting and non-reflecting light) are set on the surface of the measured shaft along the axial distance of a certain length. The reflective gratings can be formed by machining or heat treatment, and require uniform width and flat edges. In principle, mechanical processing cannot affect the mechanical characteristics of the shaft itself. The axial distance can be determined according to the installation space, material characteristics, test sensitivity and resolution requirements. The number of reflective grating stripes in the circumferential direction can be determined according to the dynamic characteristics of the test. For the convenience of data processing, it is recommended to take a multiple of 6, which is listed as 30 in this implementation.

[0017] as attached figure 1 As shown, the A / B, C / D groups of four laser fiber optic sensors use Keyence (Keyence) FS-V30 ultra-high power sensor, which can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com