Method for generating glass polishing machining path of five-axis numerical control machine

A technology of processing paths and CNC machine tools, which is applied in the field of generation of glass grinding processing paths for five-axis CNC machine tools, can solve problems such as low production efficiency, poor consistency of product patterns, and high requirements for technology and experience, so as to reduce production costs and shorten development. Cycle time and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

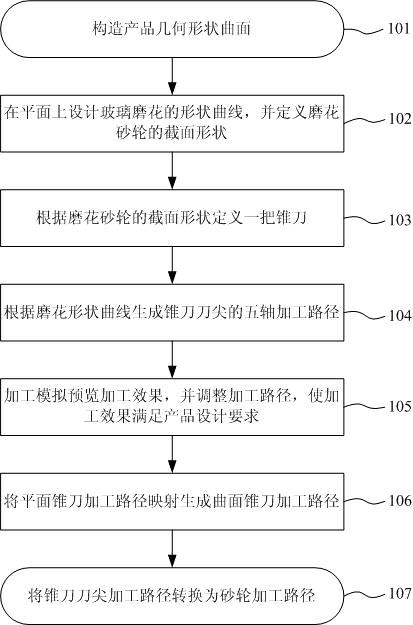

[0043] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: the flow chart of the generation method of a kind of five-axis numerical control machine tool glass grinding path of the present invention is as follows figure 1 Shown, illustrate the specific embodiment of the present invention according to the programming example of grinding flowers on the glass bottle.

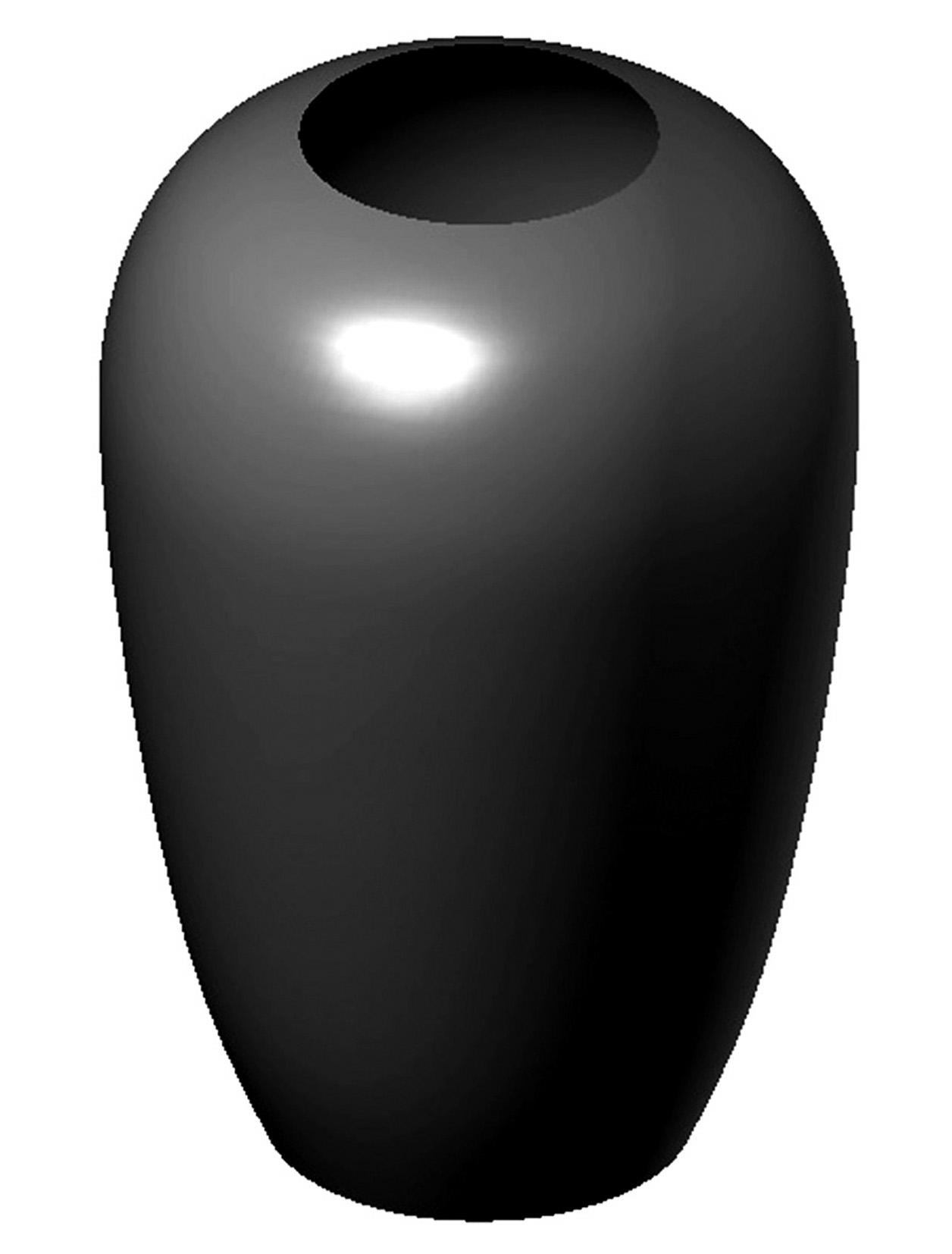

[0044] Step 101, constructing the geometric surface of the product according to the geometric data of the applied product, figure 2 A curved surface representing the shape of a glass bottle constructed in this embodiment is shown.

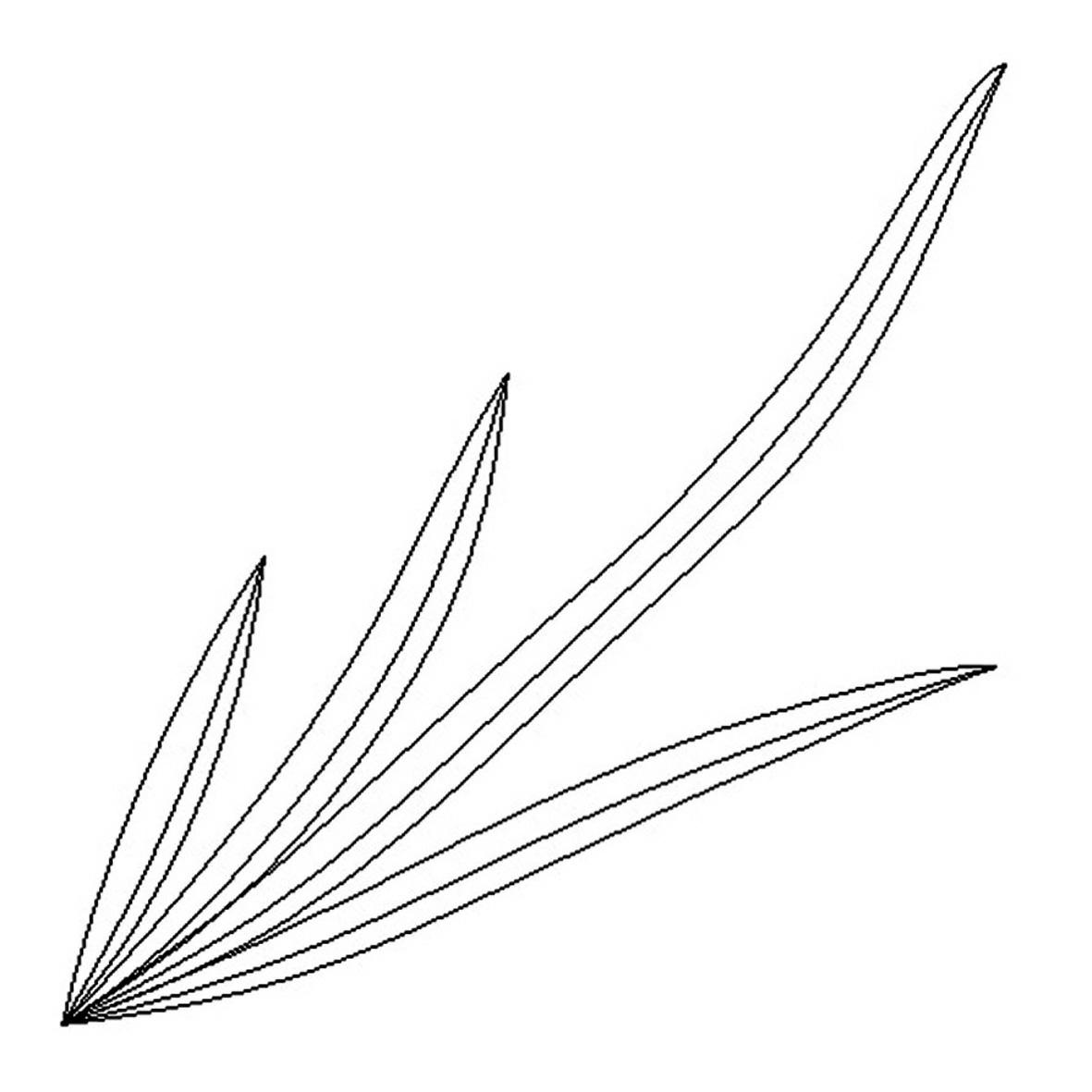

[0045] Step 102, designing a pattern curve on the plane, and defining the cross-sectional shape of the pattern wheel according to the designed pattern shape. image 3 Shown is the milled shape curve in this embodiment, Figure 4 What 10 represented in the middle is the selected emery wheel according to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com