Wire drawing and taking up device for enamelling machine

A wire take-up device and enamelling machine technology, applied in the direction of electrical components, circuits, conductor/cable insulation, etc., can solve the problems that affect the quality of finished wires, cannot adjust the wire drawing speed or take-up speed independently, and pull off, etc., to achieve stable The effect of drawing quality, improving the quality of finished line, and avoiding excessive stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

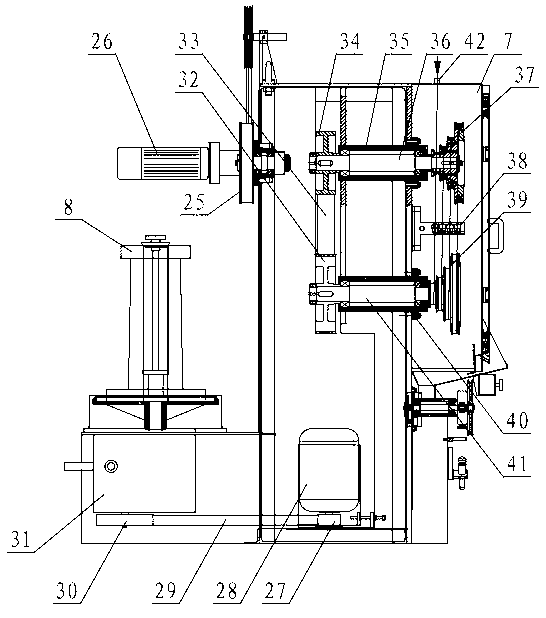

[0017] See image 3 , the take-up motor 28 is installed on the bottom of the frame 4, the take-up motor pulley 27 is installed on the output end of the take-up motor 28, is connected with the take-up pulley 30 by a belt 29, and the take-up pulley 30 is connected by a reduction box 31 The rotating shaft of take-up reel 8.

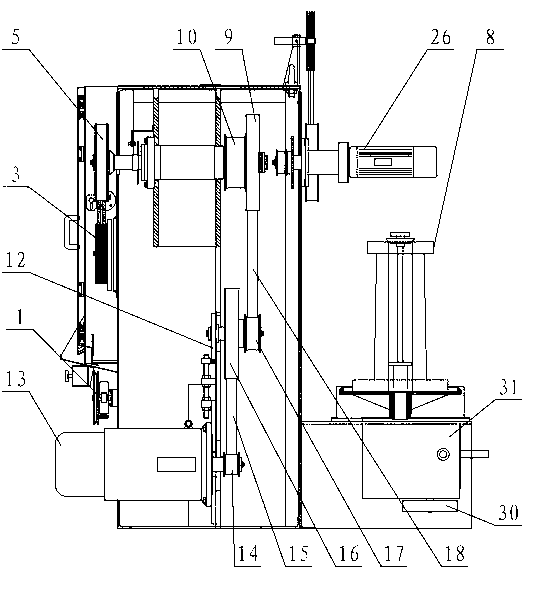

[0018] See Figure 4 , the output end of the take-up fixed-speed wheel motor 26 is equipped with a pulley 21, and the pulley 21 is connected with the pulley 22 by a synchronous belt 20; Line fixed speed wheel 25, take-up line fixed speed wheel axle 23 is installed on frame 4 by bearing block 24. The wire reel of take-up fixed speed wheel 25 is connected with the wire reel of take-up reel 8 by enameled wire wire rod.

[0019] See Figure 4 , The wire drawing fixed speed wheel shaft 19 is installed in the bearing block 11, the wire drawing fixed speed wheel 5 and the second pulley 10 and the first pulley 9 are respectively installed at the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com