Special bamboo feller

A harvester and bamboo technology, applied in the application, forestry, agriculture and other directions, can solve the problems of increased bamboo harvesting cost, slow artificial harvesting rate, affecting the quality of bamboo materials, etc., achieving light weight, good economic and social benefits, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

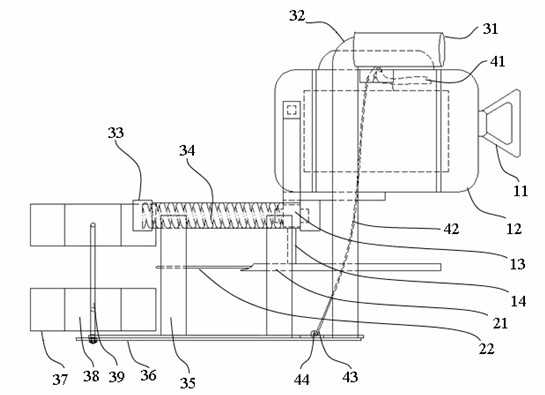

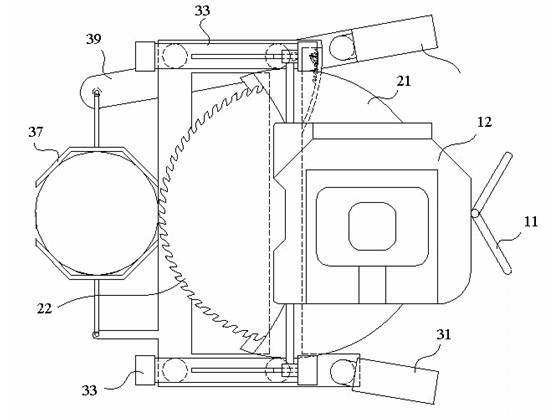

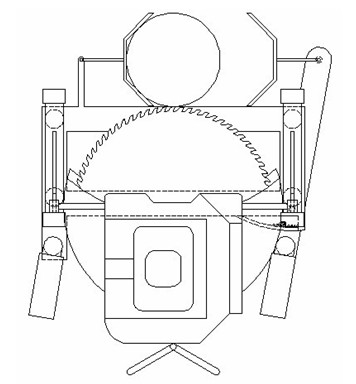

[0015] Such as figure 1 and 2 Shown, forest and bamboo felling machine is made up of power unit, cutting device, fixing device, control device. Power device is made up of handle 11, gasoline engine 12, reducer 13, adapter 14; The cutting device consists of a protective cover 21 and a circular saw 22, and the protective cover 21 is placed at the outer end of the circular saw 22 to play a protective role when the circular saw 22 works. Fixture is made up of fixed bar 31, rotating shaft 32, slide rail 33, spring 34, bracing frame 35, chassis 36, gripper 37, rubber sheet 38, connecting rod 39. The fixed rod 31 can rotate around the rotating shaft 32, and the front part of the fixed rod 31 is connected with the handle 37 through the connecting rod 39; above; the spring 34 is placed inside the slide rail 33, which acts as a buffer for the cutting system when it is working; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com