Water seal dust removing device of gas producer

The technology of a gas generator and a dust removal device is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents. It can solve the problems of low dust removal efficiency, blockage of conveying pipes, and dangers, and achieves ingenious and reasonable structure and improved efficiency. High dust removal capacity and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

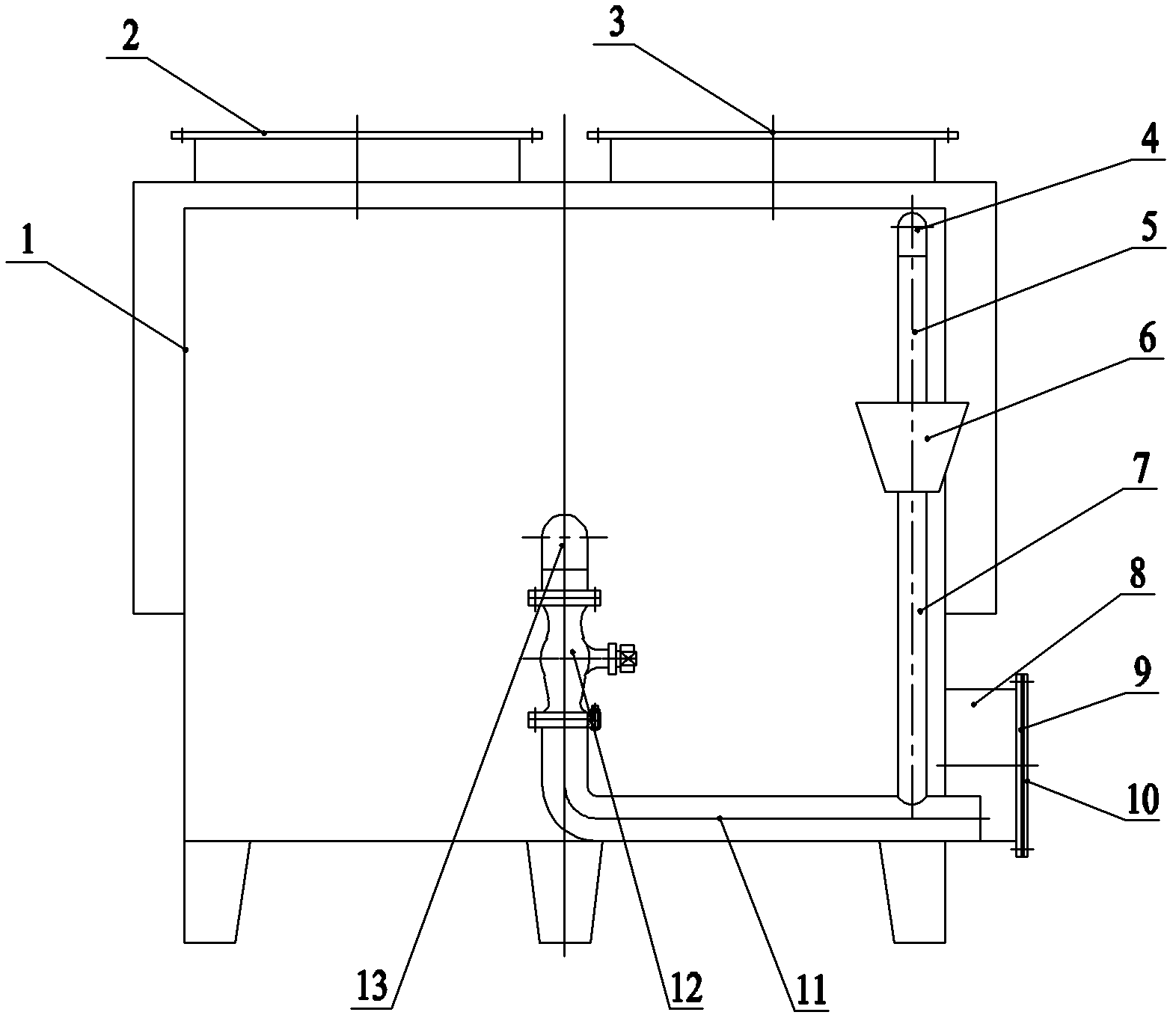

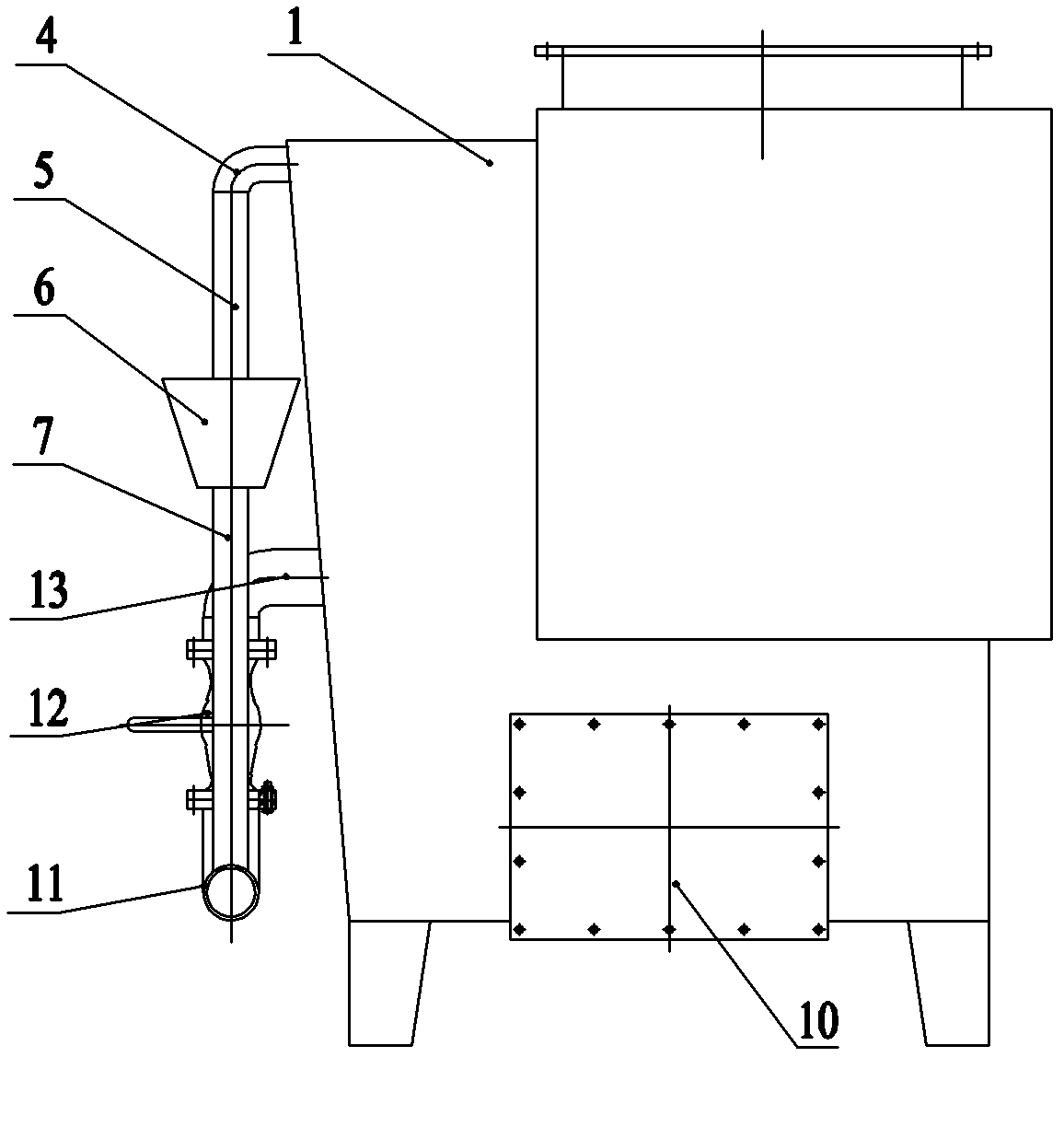

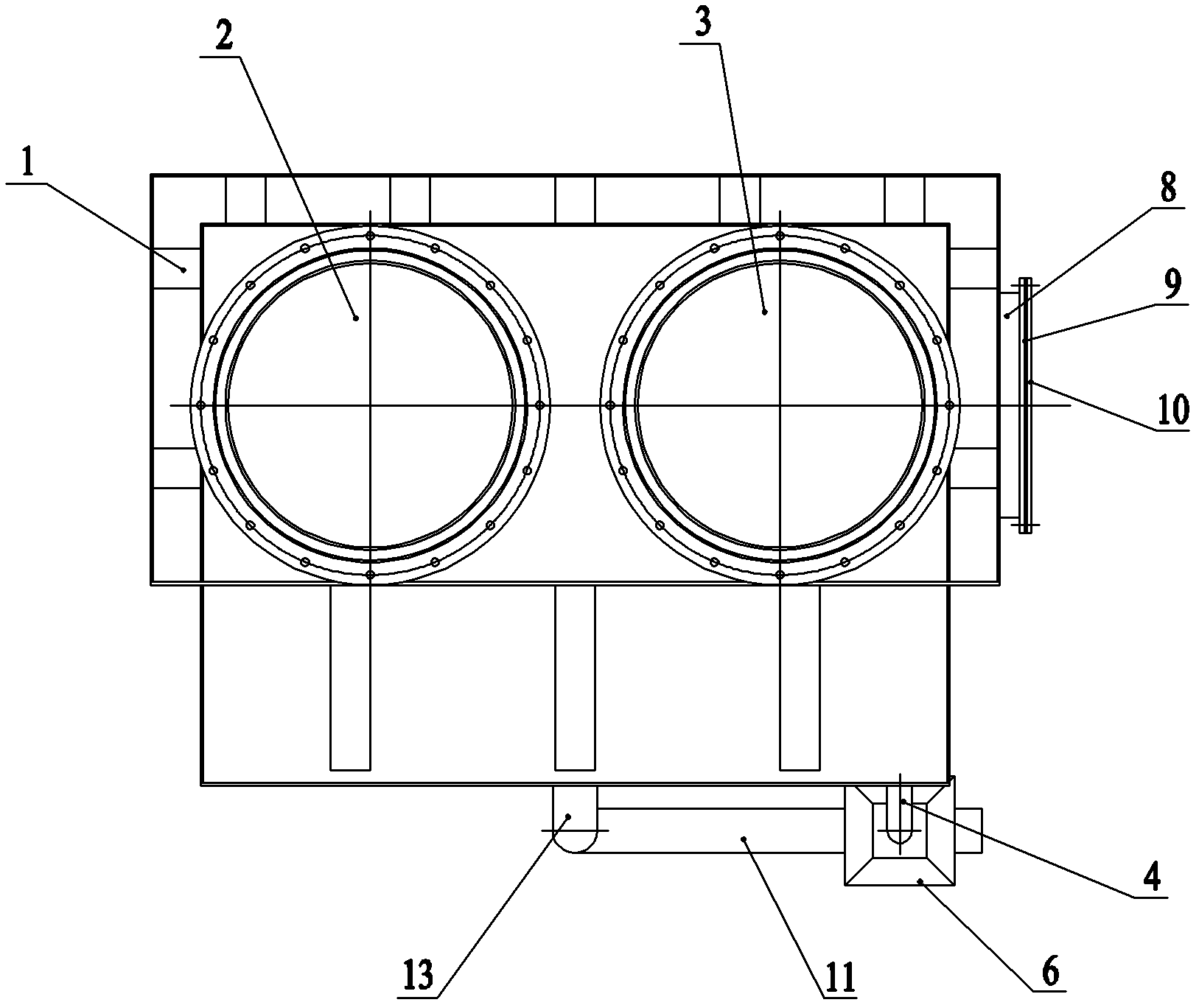

[0016] As shown in the figure: the water-sealed dust removal device of the gas generator in the embodiment is mainly composed of a dust removal body 1, an overflow elbow 4, an upper overflow pipe 5, a water outlet 6, a lower overflow pipe 7, and a rubber sealing plate 9 cover plate 10. It is composed of parts such as water discharge pipe 11, ball valve 12 and water discharge elbow 13.

[0017] Such as figure 1 As shown, the dust removal main body 1 is cavity type and made of steel material. The dust removal main body 1 is filled with water. The top of the dust removal main body 1 is provided with an air inlet 2 for connecting the air intake pipeline and an air inlet for connecting the air outlet pipeline. The air outlet 3 of the dust removal body 1 is provided with a slag removal port 8 on the lower side of the dust removal body 1, and a rubber sealing plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com