Coal purifying equipment changing pipeline and an anticracking method thereof

A technology for transforming pipelines and purification equipment, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of shortened service life of the transformed pipeline system, influence on the operating efficiency of purification equipment, and rupture of transformed pipelines, so as to improve the anti-cracking effect, Effect of preventing cracking and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method and device for preventing cracking of a converted pipeline according to the present invention will be described in detail below through an exemplary embodiment with reference to the accompanying drawings.

[0024] Before explaining the present invention, firstly, a brief description will be made on the cracking of the transformation pipeline when the prior art process is adopted. So that those skilled in the art can more fully understand the design principle of the present invention.

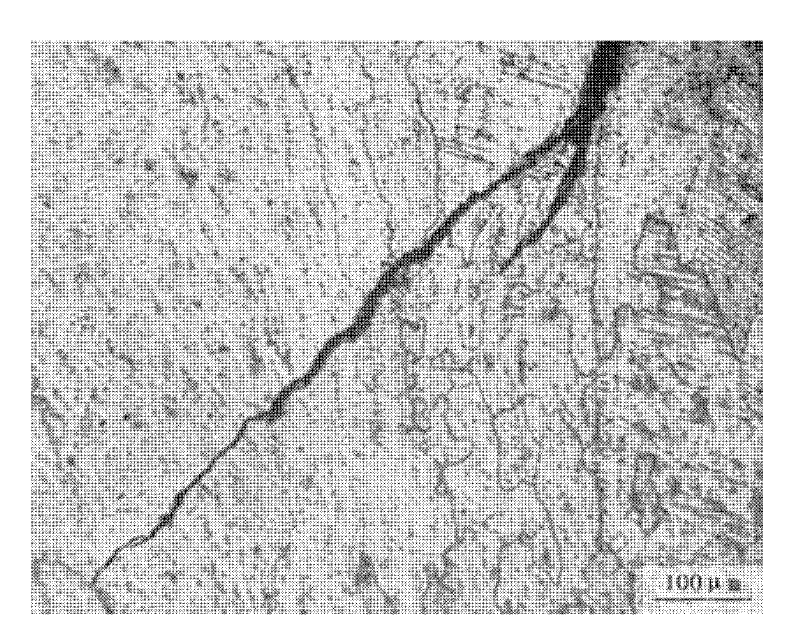

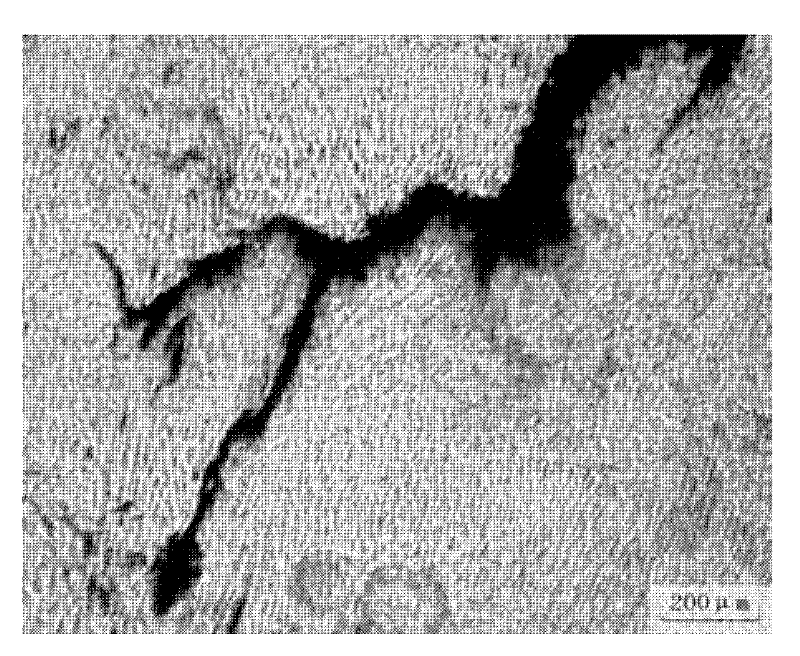

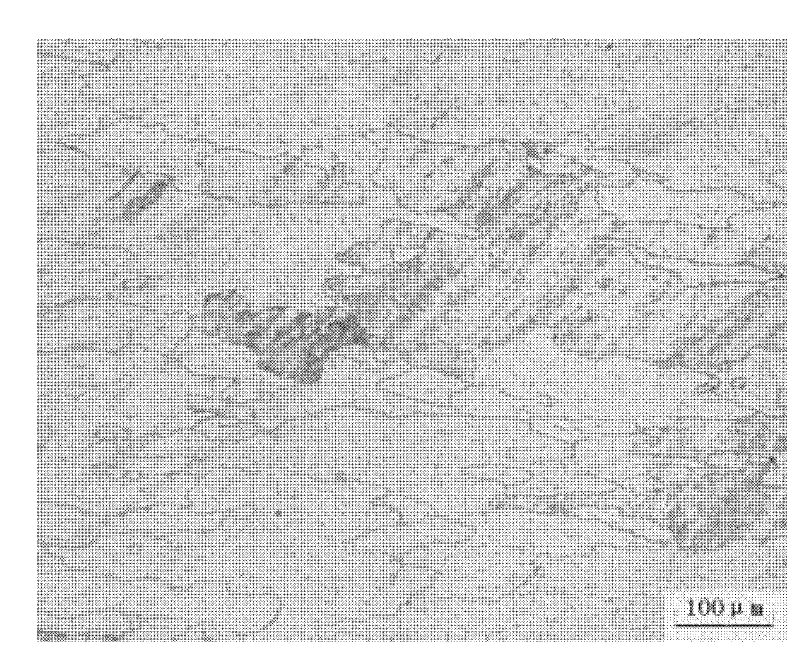

[0025] First refer to figure 1 with figure 2 , which shows a metallographic image of cracking of a transformed pipe using a prior art process flow. It can be seen from the metallographic diagram that the cracks in the pipe wall are transgranular and have few bifurcations. It is confirmed by metallographic analysis that the cracks belong to stress corrosion cracking, and the characteristics of sulfide corrosion are obvious. Furthermore, when the metallographic specimen was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com