Module surface cleaning device and module surface cleaning method

A technology for surface cleaning devices and components, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as crystalline silicon solar cell components or thin-film solar cell panels cannot generate electricity normally, and achieve improved Effect of stability, clean light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

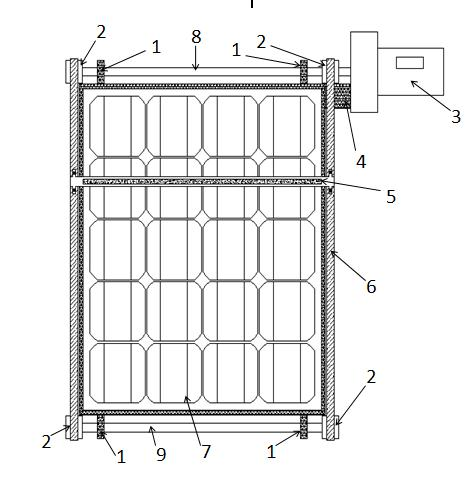

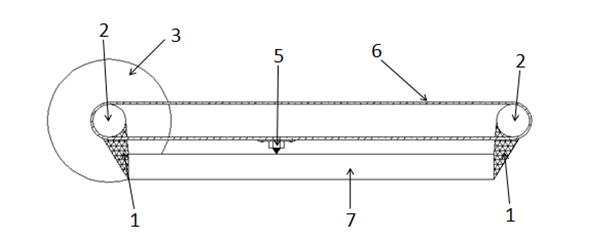

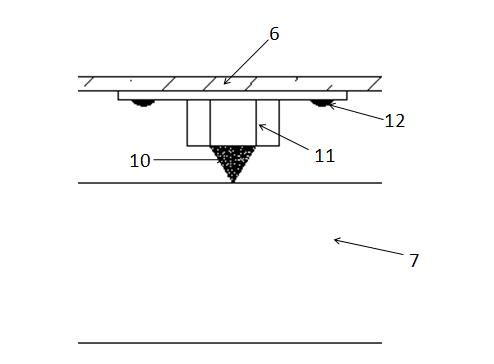

[0021] The technical scheme of the present invention is: the wiper 5 driven by motor 3 is installed on the upper surface of crystalline silicon battery assembly 7, and one end of crystalline silicon battery assembly 7 is installed by motor 3 through fixed motor support 4, and wiper 5 regularly or rains and snows the weather to crystal The dust or rain and snow on the surface of the silicon cell assembly 7 is cleaned to realize the cleaning and sufficient light transmittance on the surface of the crystalline silicon cell assembly 7; the working surface of the wiper 5 is in close contact with the upper surface of the solar cell assembly 7; One end of the solar cell module 7 is connected to the motor 3, the output shaft of the motor 3 is connected to the driving rod 8, and the two ends of the driving rod are respectively fixed with active sawtooth rings 2; the other end of the crystalline silicon battery module 7 is provided with a follower rod 9 The two ends of the follower rod 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com