Method for producing axle beam by using preheated flash butt welding

A technology of flash butt welding and pre-flash, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as unsatisfactory product quality, achieve high fatigue strength, high dimensional accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

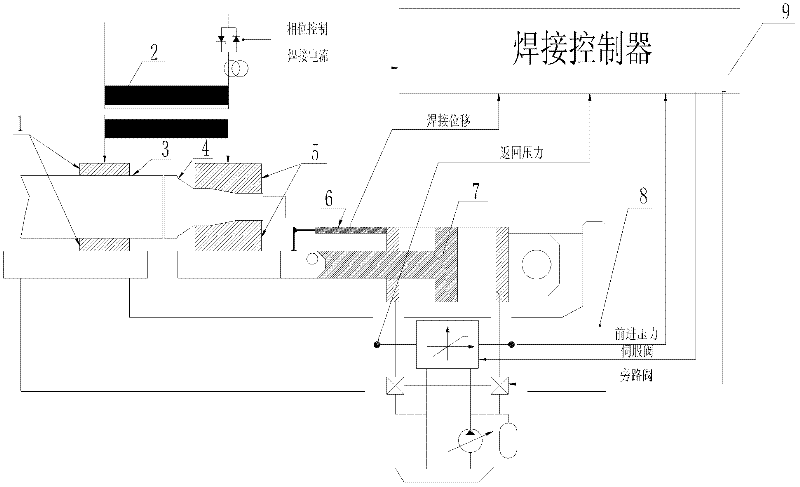

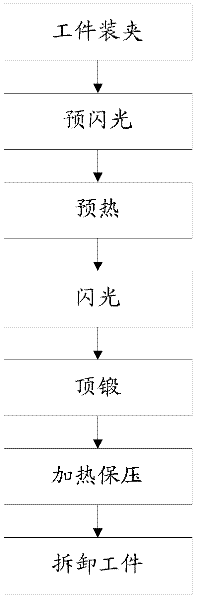

Method used

Image

Examples

Embodiment 1

[0061] 1. Shaft head and shaft tube material——Q345

[0062] 2. Workpiece end face size - 150×150×11 hollow square tube (see Figure 6 ), cross-sectional area 5540mm 2

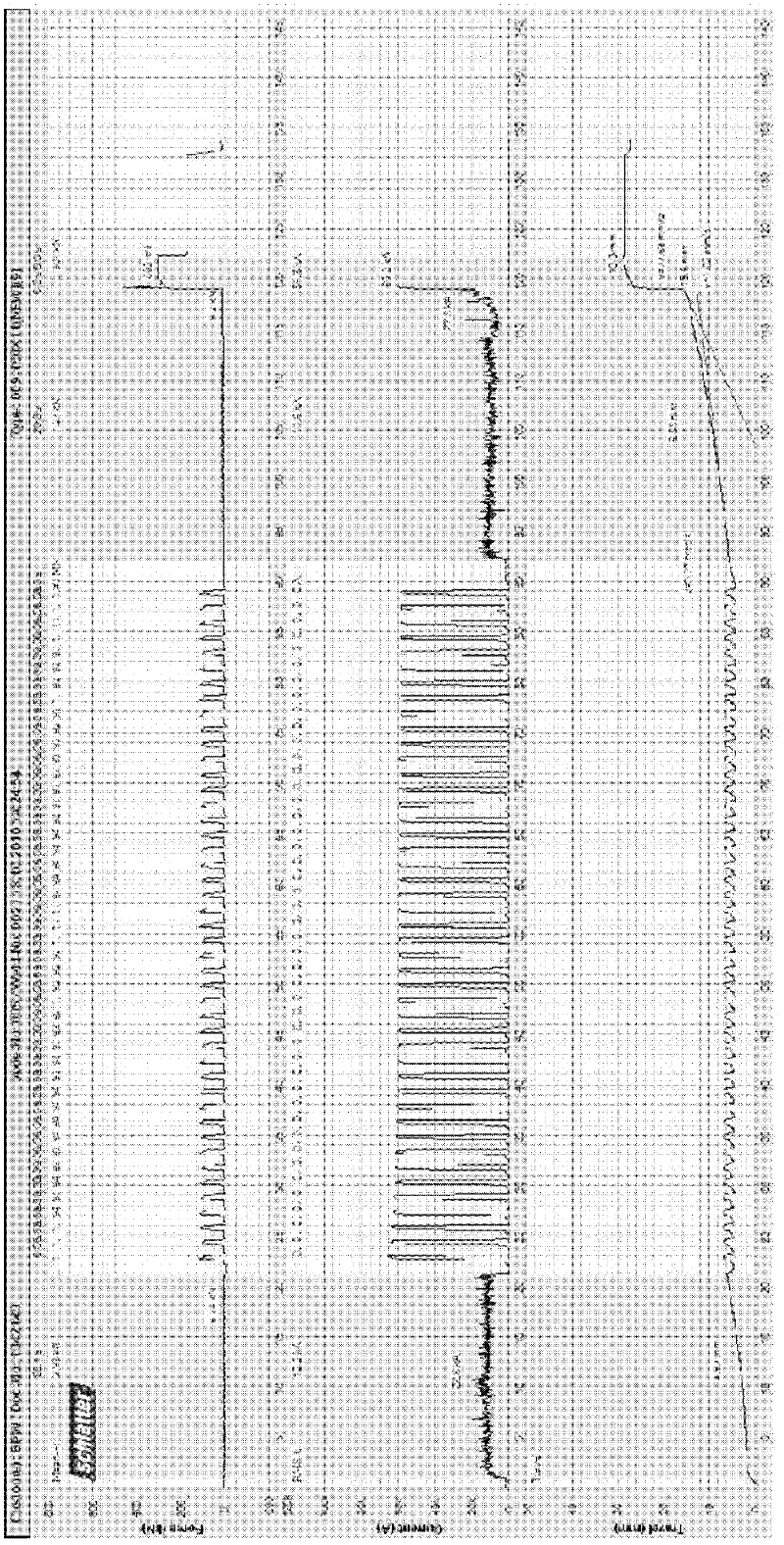

[0063] 3. Welding process——(1) Pre-flash: The flash margin is about 5mm, and the flash speed is 0.25mm / s; (2) Preheating: There are 46 preheating pulses in total, and in each pulse, the workpiece contact heating time 0.9 seconds, the heating current is 60kA, the pressure applied between the two workpieces is 100kN during heating, the time for the two workpieces to separate for thermal diffusion is 0.6 seconds each time, and the distance between each separation is 1.5mm; (3) Flash: minutes Two stages, the flash speed of the first stage is 0.25mm / s, and the flash margin is 7mm; the flash speed of the second stage is 0.32mm / s, and the flash margin is 3mm; (4) Upsetting: Upsetting force 400kN, current 60kA, loading time 0.6 seconds, the total upsetting allowance is 13mm; (6) Heating and holding pressure: divided...

Embodiment 2

[0066] 1. Shaft head and shaft tube material——Q345.

[0067] 2. Workpiece end face size - 150×150×16 hollow square tube (see Figure 6 ), the cross-sectional area is 7800mm 2 .

[0068] 3. Welding process——(1) Pre-flash: The flash margin is about 4.5mm, and the flash speed is 0.2mm / s; (2) Preheating: There are 44 preheating pulses in total. In each pulse, the workpiece is in contact with the heated The time is 1.1 seconds, the heating current is 64kA, the pressure applied between the two workpieces during heating is 160kN, the time for the two workpieces to separate for thermal diffusion is 0.5 seconds each time, and the distance between each separation is 1.5mm; (3) Flash: It is divided into two stages, the flash speed of the first stage is 0.5mm / s, and the flash margin is 7.5mm; the flash speed of the second stage is 0.8mm / s, and the flash margin is 6.5mm; (4) Upsetting: upsetting force 500kN, current 67kA , the loading time is 1 second, and the total upsetting allowance ...

Embodiment 3

[0071] 1. Shaft head and shaft tube material——Q345.

[0072] 2. The size of the workpiece end face——Φ127×17.5 hollow tube (see see Figure 7 ), cross-sectional area 6020mm 2 .

[0073] 3. Welding process——(1) Pre-flash: The flash flux is about 5mm, and the flash speed is 0.3mm / s; (2) Preheating: There are 46 preheating pulses in total. In each pulse, the contact heating time of the workpiece is 1.0 seconds, the heating current is 60kA, the pressure applied between the two workpieces during heating is 110kN, the time for the two workpieces to separate for thermal diffusion is 0.6 seconds each time, and the distance between each separation is 1.5mm; (3) Flash: divided into two In the first stage, the flash speed is 0.37mm / s, and the flash margin is 7mm; in the second stage, the flash speed is 0.5mm / s, and the flash margin is 5.5mm; (4) Upsetting: Upsetting force 400kN, current 60kA, loading time 0.6 seconds, the total upsetting allowance is 15mm; (6) Heating and holding press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com