Positioning fixture structure for automatically correcting gear transmission

An automatic correction and gear transmission technology, which is applied in the field of processing fixtures, can solve the problems of large operable objects and equipment repair and maintenance, affecting product processing accuracy, and complex overall structure, so as to achieve compact overall design structure, good positioning, and Good transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

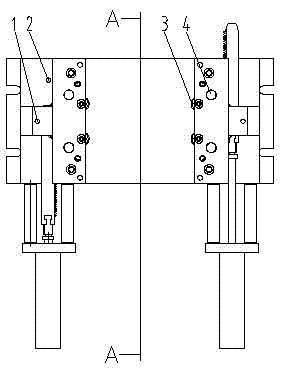

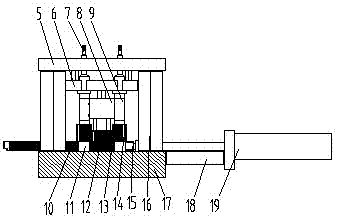

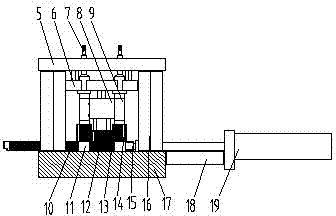

[0019] Such as Figure 1 to Figure 2 As shown, the icon numbers are explained as follows: limit guide block 1, limit error prevention pin 2, self-centering bearing 3, positioning guide column 4, centering guide plate 5, lower pressure pull plate 6, positioning locking screw 7, Compression cylinder 8, guide connecting column 9, driving force transmission gear 10, positioning and locking connecting pin 11, coaxial transmission double gear 12, bearing 13, transmission gear 14, rack device 15, support column 16, installation base plate body 17 , cylinder support column 18, cylinder 19.

[0020] In the embodiment of the present invention, the gear transmission automatic correction positioning fixture structure includes a rack device 15 that is matched, a coaxial double gear 12, a power transmission force gear 10, and the tail of the shaft end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com