Method for determining mineral aggregate gradation range based on gradation variability of raw materials

A determination method and gradation technology, which is applied in the field of determination of the gradation range of mixed materials and minerals, can solve the problems of large variability in particle composition, material variability is not considered, and synthetic gradation curves are not representative.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] [Example 1]: An expressway intends to use cement-stabilized macadam as the base material. The design gradation is shown in Table 1. The design requires that the representative value of the 7d unconfined compressive strength of the cement-stabilized macadam base is not less than 5MPa. The material is composed of 5 grades of raw materials, which are 19~26.5mm, 13.2~19mm, 9.5~13.2mm, 4.75~9.5mm, 0~4.75mm, try to determine the reasonable fluctuation range of mineral material gradation according to the variability of raw materials .

[0039] Table 1 Design gradation of cement-stabilized crushed stone

[0040] Mesh size mm

26.5

19

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

pass percentage%

100

84

68.5

57.5

40

26.5

17.5

11.5

7.5

5

3.5

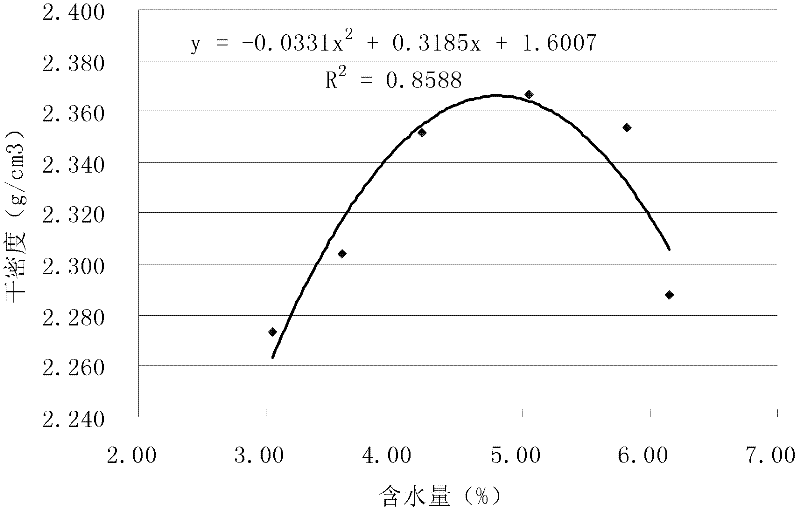

[0041] According to above-mentioned content of the invention, concrete implementation st...

Embodiment 2

[0072] [Example 2]: The design gradation of AC10 asphalt concrete for a certain expressway is shown in Table 7. The material is composed of 0-3mm, 3-5mm, 5-10mm, and mineral powder. It is determined according to the variability of raw materials. Reasonable fluctuation range of mineral material gradation. The design requires that the dynamic stability of the rutting test is not less than 2000 times / mm, the relative deformation of the rutting test is not more than 5%, the maximum bending and tensile strain of the trabecular bending test is not less than 5000 microstrain, and the immersion Marshall residual stability of water stability is not less than 80%.

[0073] Table 7AC10 Asphalt Concrete Design Gradation

[0074] Mesh size mm

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

pass percentage%

100

97.5

35

27.3

21.3

16.8

13.1

10.2

8.0

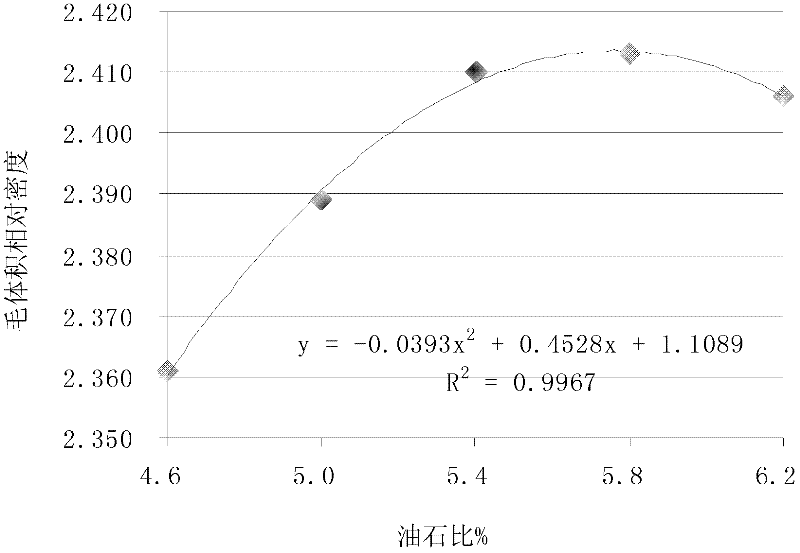

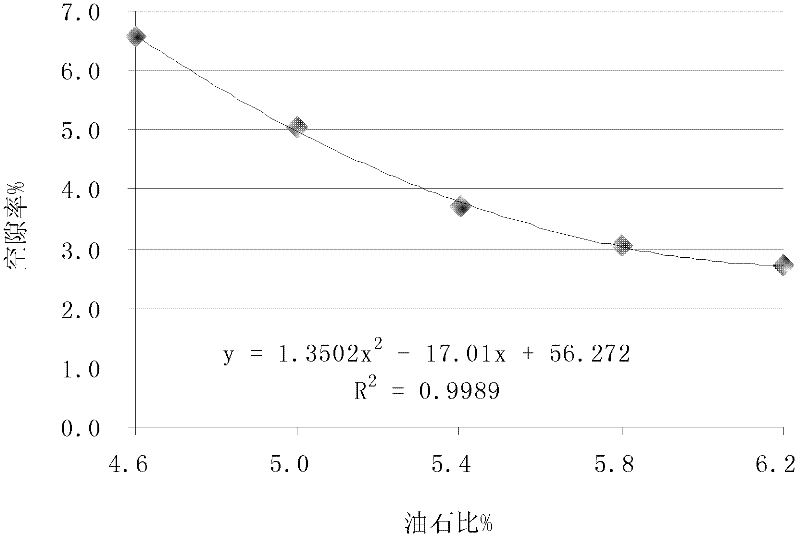

[0075] Accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com