Vermiculite and nanometer silica composite nanometer multi-hole heat insulation plate and manufacturing method thereof

A nano-silicon dioxide and nano-porous technology, applied in the field of thermal insulation materials, can solve the problems of increasing material costs, high cost of nano-silicon dioxide porous thermal insulation materials, and reducing the high-temperature thermal conductivity of nano-silicon dioxide porous thermal insulation materials. Achieve the effect of improving mechanical properties and improving high temperature heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

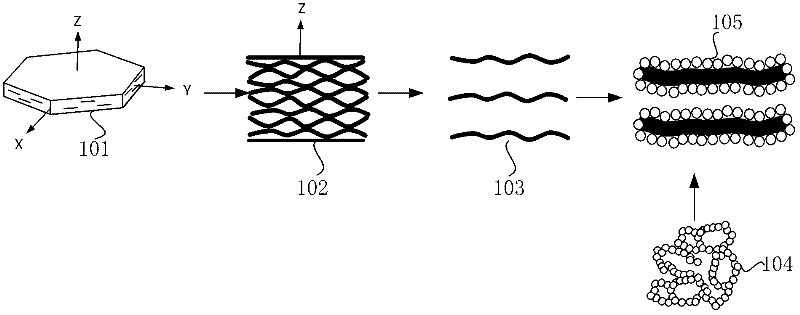

[0022] The natural vermiculite raw ore of 0.3~2mm is heated and expanded in an extruder furnace at 500°C to form a loose bulk density of 190kg / m 3 expanded vermiculite. The expanded vermiculite after the expansion is 30% by weight, and the specific surface area is 200m 2 The nano-silica per gram is compounded by 70% by weight. The prepared raw materials were premixed in a nano-coating machine at a low speed of 300 rpm for 5 minutes, and then mixed at a high speed of 1400 rpm for 20 minutes to obtain a mixed raw material.

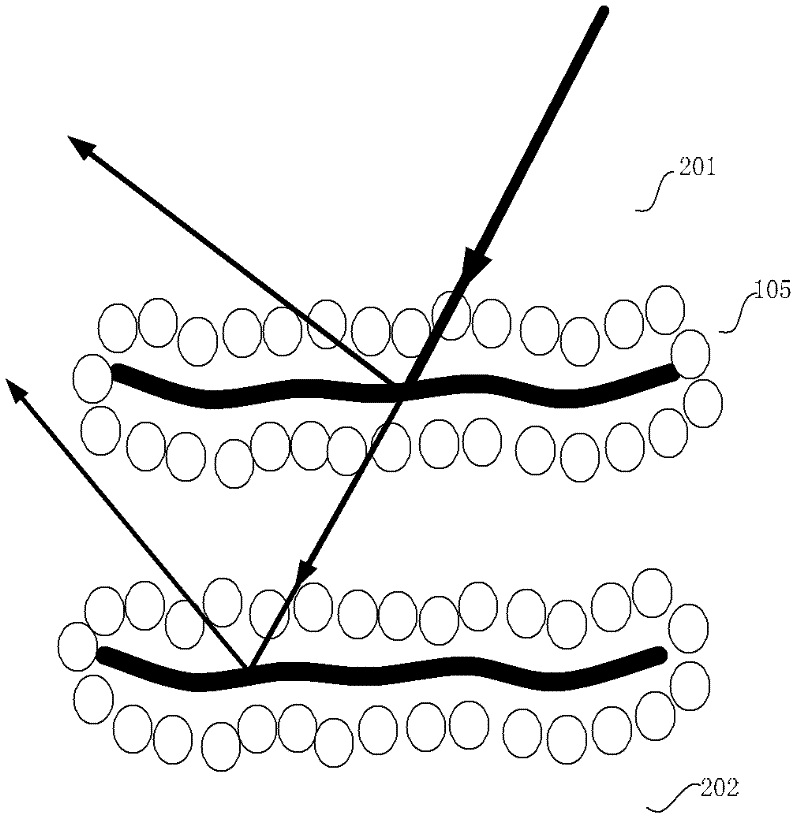

[0023] There are no expanded vermiculite particles in the mixed raw materials, and the expanded vermiculite has been peeled off into micro-nano vermiculite flakes less than 1 mm in size, forming a flaky powder. The mixed raw materials are pressed and molded under a pressure of 2.0 MPa in a molding device equipped with a negative pressure device to obtain the composite nanoporous insulation board of vermiculite and nano silicon dioxide of the present invent...

specific Embodiment 2

[0032] The natural vermiculite raw ore of 0.3~2mm is heated and puffed in an extruder furnace at 850°C to form a loose bulk density of 150kg / m 3 expanded vermiculite. The expanded vermiculite after the expansion is 50% by weight, and the specific surface area is 200m 2 The nano-silica per gram is compounded by 50% by weight. The prepared raw materials were premixed in a nano-coating machine at a low speed of 300 rpm for 5 minutes, and then mixed at a high speed of 1400 rpm for 20 minutes to obtain a mixed raw material.

[0033] There are no expanded vermiculite particles in the mixed raw materials, and the expanded vermiculite has been peeled off into micro-nano vermiculite flakes less than 1 mm in size, forming a flaky powder. The mixed raw materials are pressed and molded under a pressure of 2.0 MPa in a molding device equipped with a negative pressure device to obtain the composite nanoporous insulation board of vermiculite and nano silicon dioxide of the present inventio...

specific Embodiment 3

[0042] The 0.3-2mm natural vermiculite fragments are heated and puffed in the puffing furnace at 900°C to form a loose bulk density of 80kg / m 3 expanded vermiculite. The expanded vermiculite after the expansion is 60% by weight, and the specific surface area is 200m 2 The nano-silica per gram is compounded by 40% by weight. The prepared raw materials were premixed in a nano-coating machine at a low speed of 300 rpm for 5 minutes, and then mixed at a high speed of 1400 rpm for 20 minutes to obtain a mixed raw material.

[0043] There are no expanded vermiculite particles in the mixed raw materials, and the expanded vermiculite has been peeled off into micro-nano vermiculite flakes less than 1 mm in size, forming a flaky powder. The mixed raw materials are pressed and molded under a pressure of 2.0 MPa in a molding device equipped with a negative pressure device to obtain the composite nanoporous insulation board of vermiculite and nano silicon dioxide of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com