Method for preparing modified epoxy acrylate

A technology of epoxy acrylate and hydroxy acrylate, applied in the field of preparing modified epoxy acrylate, can solve the problems of adverse effects of acrylic substrate and cured film, difficult temperature control, etc., and achieve the effect of increasing molecular weight and reducing Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

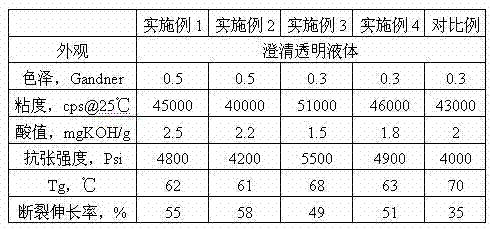

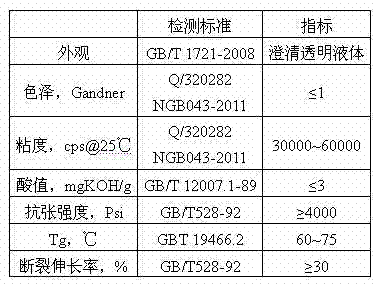

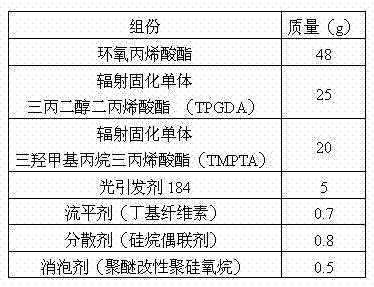

Examples

Embodiment 1

[0034] (1) Synthesis of intermediates: Add 98 kg of maleic anhydride, 116 kg of hydroxyethyl acrylate, 0.3 kg of hypophosphorous acid and 0.5 kg of p-hydroxyanisole into the reactor in sequence, stir evenly, and heat up to 90°C for 2.5 Hours, check the acid value to the theoretical value (212mgKOH / g), discharge (denoted as A), and stand by;

[0035] (2) Organic acid chain extension: Put 464 kg of epoxy resin 828, 15 kg of adipic acid and 1 kg of triethylamine into the reaction kettle according to the formula, stir evenly, slowly raise the temperature to 90°C for 3 hours, and check the acidity. After the value is less than or equal to 1 mgKOH / g, turn on the cooling water and reduce the temperature to 50°C;

[0036] (3) Esterification reaction at elevated temperature: Add material A, 2 kg of triethylamine, 0.8 kg of p-hydroxyanisole, 2 kg of 2,5-dimethylhydroquinone, and 0.2 kg of hypophosphorous acid in sequence according to the formula In the reaction kettle; heat up, when th...

Embodiment 2

[0041] (1) Synthesis of intermediates: Add 98 kg maleic anhydride, 116 kg hydroxyethyl methacrylate, 0.3 kg hypophosphorous acid and 0.5 kg p-hydroxyanisole into the reaction kettle in sequence, stir evenly, and heat up to 80°C React for 3 hours, check the acid value to (212mgKOH / g), discharge (recorded as A), and set aside;

[0042] (2) Organic acid chain extension: Put 464 kg of epoxy resin 828, 15 kg of adipic acid and 1 kg of triethylamine into the reaction kettle according to the formula, stir evenly, slowly raise the temperature to 95°C for 3 hours, and check the acid After the value is less than or equal to 1 mgKOH / g, turn on the cooling water and reduce the temperature to 60°C;

[0043] (3) Esterification reaction at elevated temperature: Add material A, 2 kg of triethylamine, 0.8 kg of p-hydroxyanisole, 2 kg of 2,5-dimethylhydroquinone, and 0.2 kg of hypophosphorous acid in sequence according to the formula In the reaction kettle; heat up, when the temperature reache...

Embodiment 3

[0048] (1) Synthesis of intermediates: Add 139 kg of phthalic anhydride, 106 kg of hydroxyethyl acrylate, 0.3 kg of hypophosphorous acid and 0.5 kg of p-hydroxyanisole into the reactor in sequence, stir evenly, and heat up to 110°C for 2.5 hours , after checking the acid value to the theoretical value (212 mgKOH / g), discharge the material (denoted as A) and wait for use;

[0049] (2) Organic acid chain extension: Put 414 kg of epoxy resin 828, 14 kg of sebacic acid and 1 kg of triphenylphosphine into the reaction kettle according to the formula, stir evenly, slowly raise the temperature to 105°C for 2 hours, and check After the acid value is ≤1 mgKOH / g, turn on the cooling water and reduce the temperature to 65°C;

[0050] (3) Esterification reaction at elevated temperature: Add material A, 2 kg of triphenylphosphine, 0.5 kg of p-hydroxyanisole, 2 kg of 2,5-dimethylhydroquinone, and 0.2 kg of hypophosphorous acid in sequence according to the formula Put it into the reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com