Warm-mix modified asphalt and method for preparing asphalt mixture by using same

A modified asphalt and warm mix technology, which is applied in the preparation of warm asphalt mixture and in the field of warm mix asphalt mixture, can solve the problems of high energy consumption, environmental pollution, low mixing, paving, compaction temperature, etc., to achieve Reduce construction temperature, reduce environmental damage, and prolong the effect of laying season

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

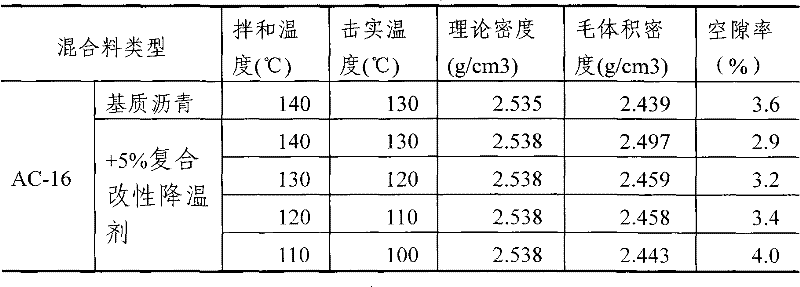

Embodiment 1

[0027] The invention is a kind of warm-mix modified asphalt, which includes base asphalt and composite modified cooling agent, the mixing weight of the composite modifier is 5% of the weight of the base asphalt, and the composite modifier is polyolefin cooling agent.

[0028] Among them, the preferred embodiment is that the polyolefin cooling agent is a single polymer or a copolymer of α-olefin and cycloolefin.

[0029]A further preferred embodiment is that the α-olefin includes any one of ethylene, propylene, butene, pentene, hexene, octene and 4-methyl-1-pentene or any combination thereof.

[0030] A further preferred embodiment also includes that the cycloolefin copolymer is a styrene-butadiene block copolymer.

[0031] A method for preparing asphalt mixture with warm-mixed modified asphalt, said method comprising the following steps:

[0032] The first step, heating the base asphalt: heating and dehydrating the base asphalt, and heating to 110 ° C ~ 130 ° C;

[0033] Th...

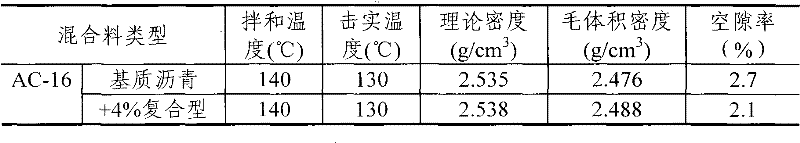

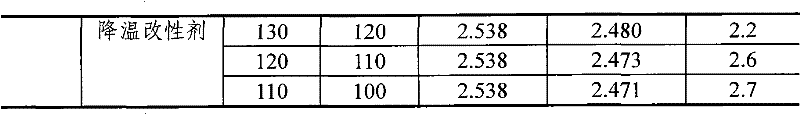

Embodiment 2

[0040] The invention is a kind of warm-mix modified asphalt, which comprises base asphalt and composite modified cooling agent, the blending weight of the composite modifier is 4% of the weight of the base asphalt, and the composite modifier is polyolefin cooling agent.

[0041] Among them, the preferred embodiment is that the polyolefin cooling agent is a single polymer or a copolymer of α-olefin and cycloolefin.

[0042] A further preferred embodiment is that the α-olefin includes any one of ethylene, propylene, butene, pentene, hexene, octene and 4-methyl-1-pentene or any combination thereof.

[0043] A further preferred embodiment also includes that the cycloolefin copolymer is a styrene-butadiene block copolymer.

[0044] A method for preparing asphalt mixture with warm-mixed modified asphalt, said method comprising the following steps:

[0045] The first step, heating the base asphalt: heating and dehydrating the base asphalt, and heating to 110 ° C ~ 130 ° C;

[0046...

Embodiment 3

[0054] The invention is a kind of warm-mix modified asphalt, which includes base asphalt and composite modified cooling agent, the mixing weight of the composite modifier is 3.5% of the weight of the base asphalt, and the composite modifier is polyolefin cooling agent.

[0055] Among them, the preferred embodiment is that the polyolefin cooling agent is a single polymer or a copolymer of α-olefin and cycloolefin.

[0056] A further preferred embodiment is that the α-olefin includes any one of ethylene, propylene, butene, pentene, hexene, octene and 4-methyl-1-pentene or any combination thereof.

[0057] A further preferred embodiment also includes that the cycloolefin copolymer is a styrene-butadiene block copolymer.

[0058] A method for preparing asphalt mixture with warm-mixed modified asphalt, said method comprising the following steps:

[0059] The first step, heating the base asphalt: heating and dehydrating the base asphalt, and heating to 110 ° C ~ 130 ° C;

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com