Biomass microwave cracking gasification unit

A pyrolysis gasification and gasification device technology, which is applied in the field of biomass microwave cracking and gasification devices, can solve the problems of gas easily clogging gas pipelines and stoves, incomplete gasification of biomass raw materials, and incomplete tar treatment, etc. Reasonable structure, fast gas production and pure gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

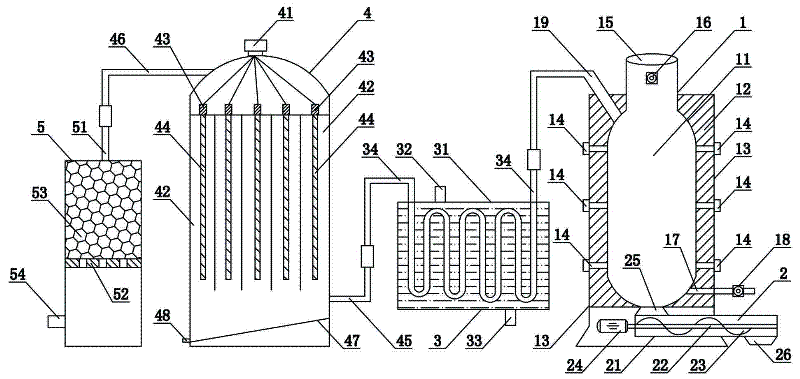

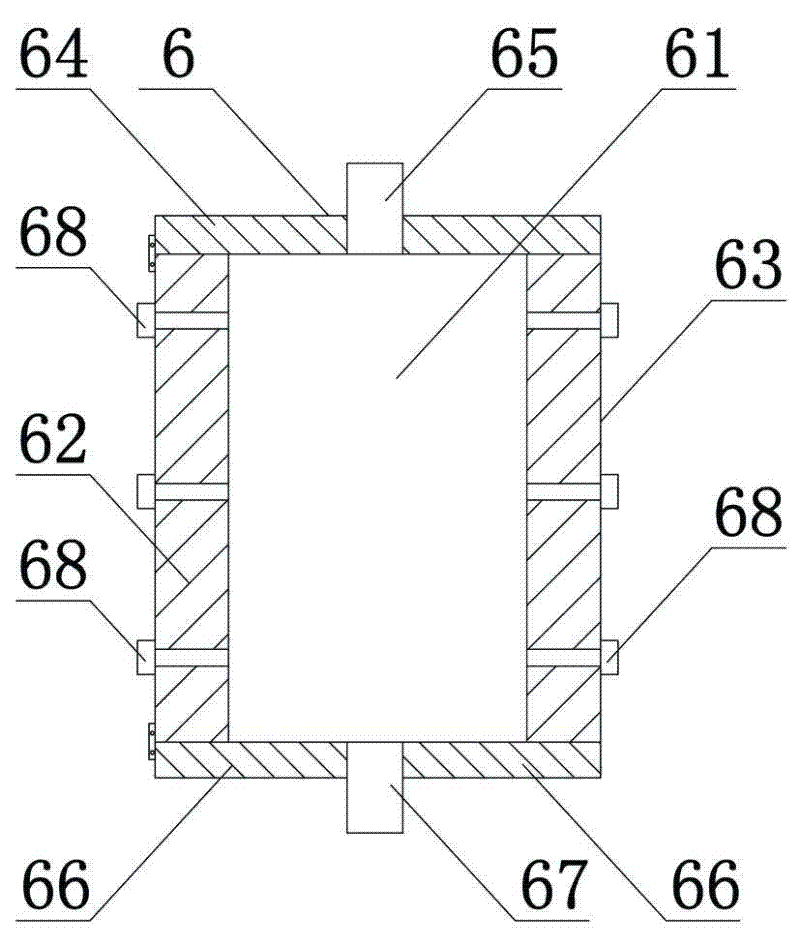

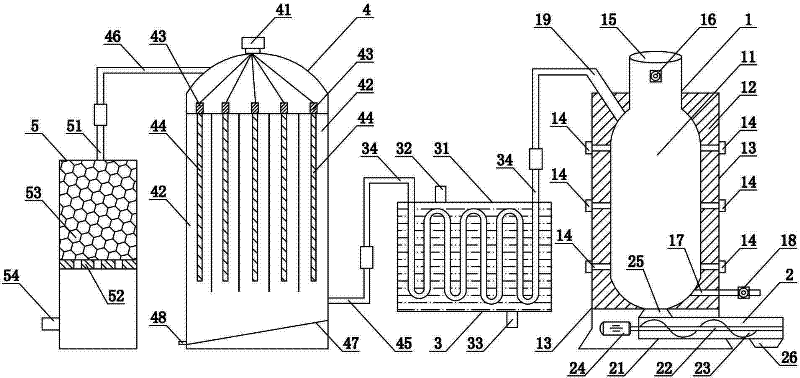

[0019] Such as figure 1 with figure 2 As shown, a biomass microwave cracking gasification device includes a microwave gasification device 1 , a spiral slagging device 2 , a gas cooling device 3 , an electric decoking device 4 , a gas drying purifier 5 and a microwave dehumidification device 6 .

[0020] The microwave gasification device 1 includes a furnace body 13, a gasification furnace 11 installed in the furnace body 13 and a microwave generator 14 installed on the furnace body 13, wherein the inner wall of the furnace body 13 is in contact with the furnace body 13 The outer walls of the gasification furnace 11 are filled with insulating materials 12, the top of the gasification furnace 11 is provided with a feed inlet 15, and the feed inlet 15 is equipped with a gas sealing valve 16, and the upper part of the gasification furnace 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com