Method for decolorizing tea seed oil

A tea seed oil and decolorization technology, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of lack of drying equipment, difficulty in decolorization of tea seed oil, and high acid value of tea seed oil, so as to achieve difficult decolorization and reduce Decolorization cost, effect of promoting decolorization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

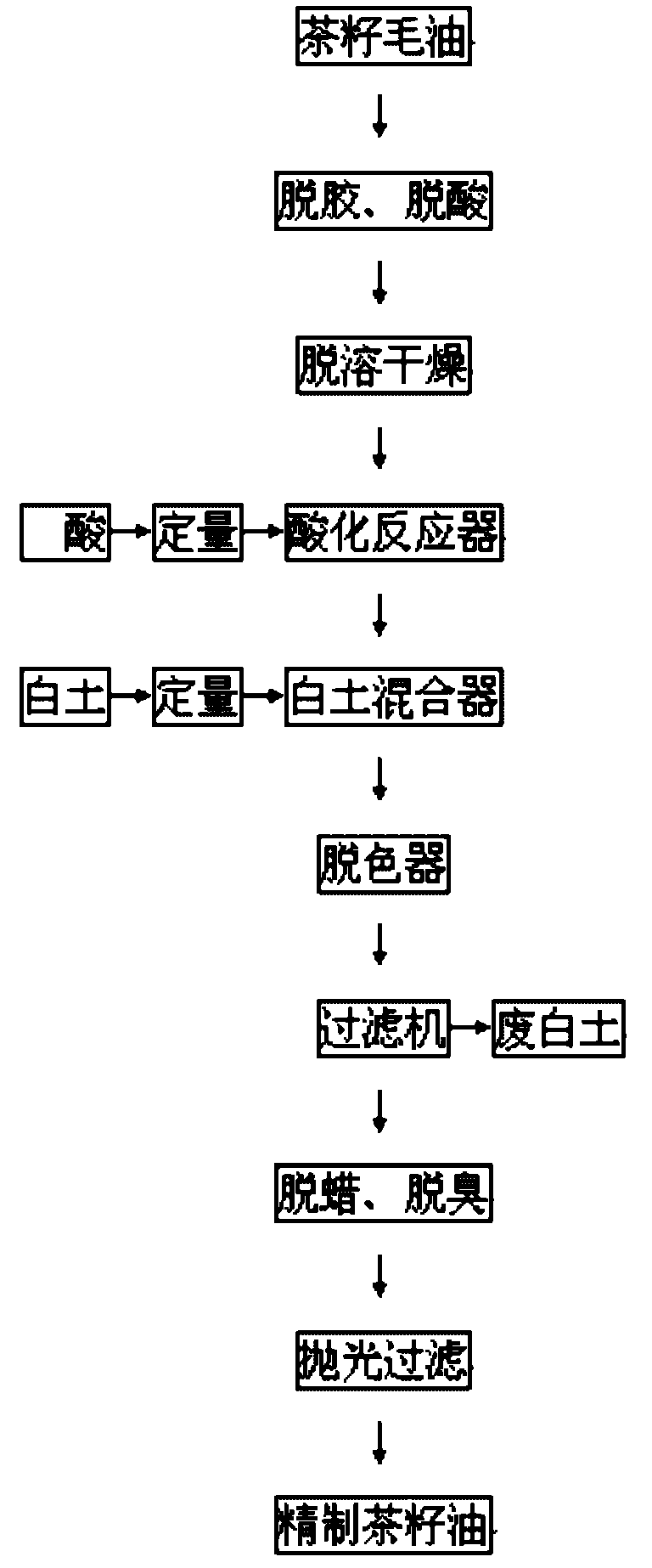

[0017] see figure 1 , a decolorization method of tea seed oil, comprising the following steps:

[0018] A. Degumming and deacidification: Add phosphoric acid of 1‰ of the weight of tea seed crude oil to tea seed crude oil with an acid value of 3mgKOH / g and mix it with tea seed crude oil to make the phospholipids in the tea seed oil absorb water and swell to form glue Then add 16 Baume NaOH to the tea seed oil containing colloidal particles by 35kg / T, mix, and make NaOH and the free fatty acid in the tea seed oil carry out neutralization reaction to form soap particles, and then the gained tea seed oil containing Colloidal particles and soap grains Tea seed oil is centrifuged through a disc centrifuge to separate the tea seed oil from the colloidal particles and soap grains, and then add soft water equal to 10% of the weight of tea seed crude oil to the separated tea seed oil , and then use a centrifugal mixer to make it fully mixed, and then use a disc centrifuge to separate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com