A regeneration method of an adsorption medium and a decolorization treatment method of printing and dyeing wastewater

A technology of adsorption medium and treatment method, which is applied in the regeneration of adsorption medium and the decolorization treatment of printing and dyeing wastewater. It can solve the problems of not having long-term use conditions and achieve the effects of regenerable adsorbent, prolonging the service life and reducing the cost of decolorization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1~6

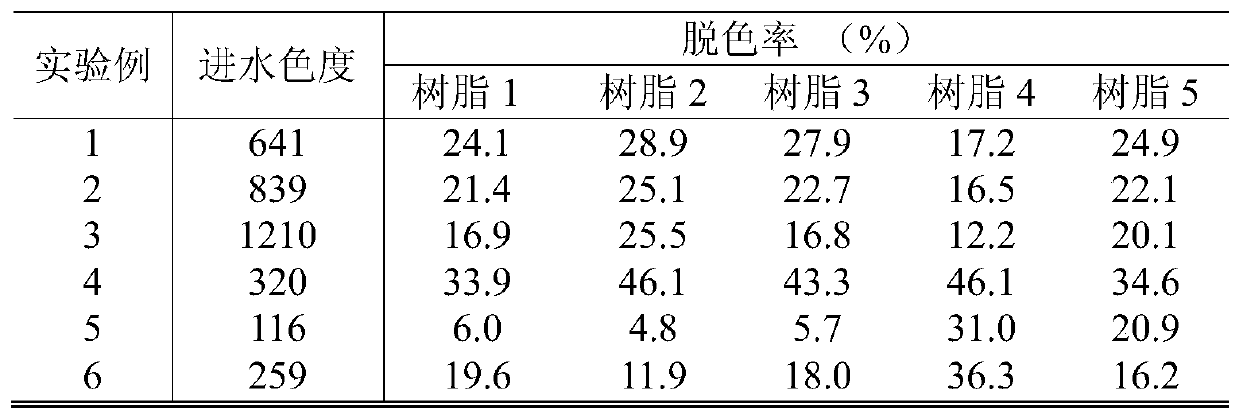

[0032] Add 10mL resin sample into the beaker, then add 50mL advanced oxidation treated water sample, mix evenly, measure the chromaticity of the supernatant after the adsorption reaches equilibrium, the results are shown in Table 1.

[0033] Wherein, resin 1 is a macroporous styrene-based strongly basic anion-exchange resin, resin 2 is a macroporous acrylic-based strongly-basic anion-exchange resin, resin 3 is a gel acrylic-based strongly-basic anion-exchange resin, and resin 4 is a macroporous Weak polarity adsorption resin, resin 5 is macroporous nonpolar adsorption resin.

[0034] Table 1 Resin decolorization effect comparison

[0035]

[0036] It can be seen from Table 1 that when the chroma of the water sample is higher (above 640), the overall adsorption performance of resin 2 is the best; when the chroma of the water sample is lower (below 320), the decolorization effect of resin 4 is more obvious.

Embodiment 1

[0046]Add 100 mL of the mixture of resin 2 and resin 4 into the chromatography column, and the mixing ratio is 1:1. The water sample after advanced oxidation treatment is added, and the flow rate is controlled at 10-20BV / h. The resin was regenerated after every 50-100BV water sample was treated.

[0047] 2BV of mixed solution of NaOH (2% by mass fraction) and NaCl (4% by mass fraction) is used for regeneration, and the flow rate is controlled at 5-20BV / h. After the regeneration is completed, a new water sample is added for the next decolorization and adsorption experiment.

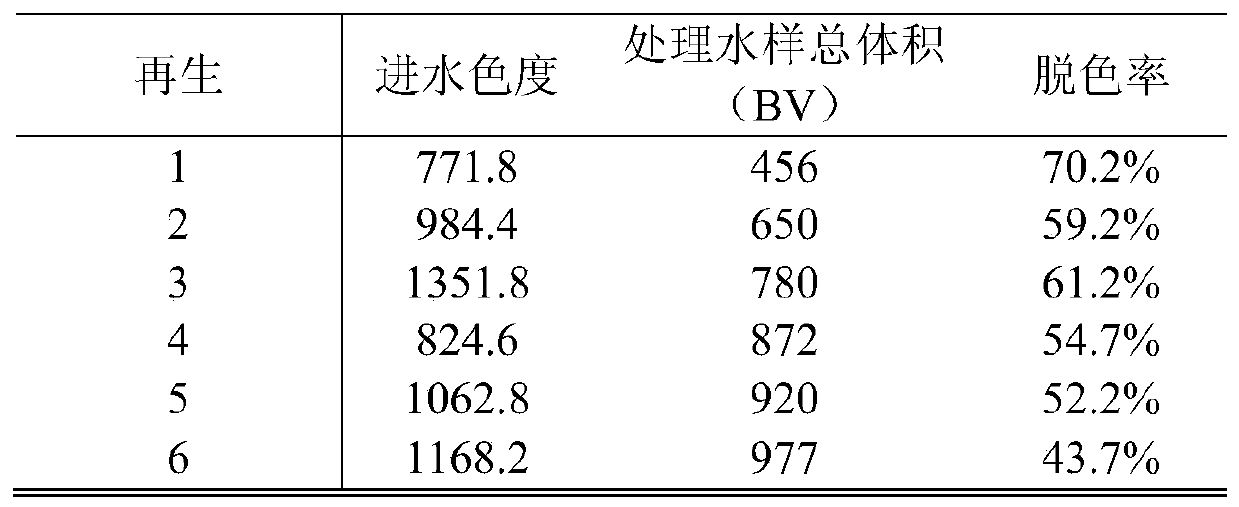

[0048] Table 3 Resin colorimetric adsorption chromatography experimental results (short regeneration cycle)

[0049]

[0050]

[0051] The results in Table 3 show that short-cycle rapid regeneration can greatly prolong the service life of resin decolorization. Compared with Comparative Example 1, the attenuation of resin adsorption capacity has been greatly reduced. However, the adsorption capaci...

Embodiment 2

[0053] Add 100 mL of the mixture of resin 2 and resin 4 into the chromatography column, and the mixing ratio is 1:1. The water sample after advanced oxidation treatment is added, and the flow rate is controlled at 10-20BV / h. Regeneration starts after every 50-100BV of water samples are processed.

[0054] The regeneration uses 2BV of NaOH (2% by mass fraction) and NaCl (4% by mass fraction) mixed solution, and the mixed solution also contains rhamnolipid at a concentration of 200ppm.

[0055] After the regeneration is completed, a new water sample is added for the next decolorization and adsorption experiment.

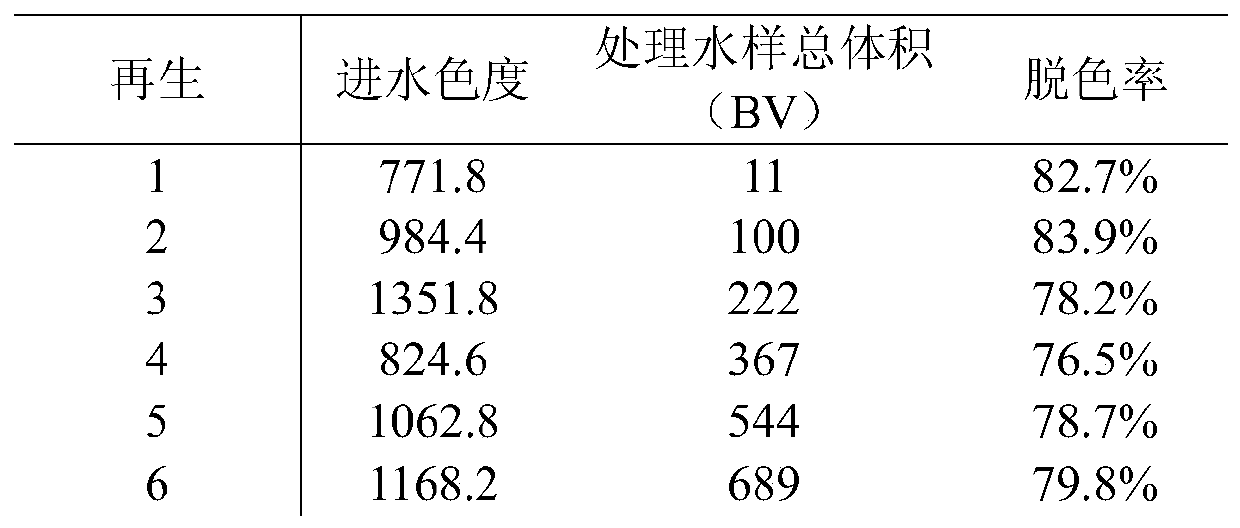

[0056] Table 4 Experimental results of resin chromaticity adsorption chromatography (short regeneration cycle + cleaning regeneration aid)

[0057]

[0058]

[0059] The results in Table 4 show that short-period rapid regeneration can greatly prolong the service life of resin decolorization. When the rhamnolipid regeneration aid is added to the regeneration sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com