Method for extracting essences from tea leaves

A technology of tea and flavor, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of low purity and quality of flavor, difficulty in meeting high-purity natural flavor, etc., and achieve short time consumption, less impurity content, and high purity of flavor high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 adopts the inventive method to extract essence from green tea

[0027] Green tea 1kg, source of green tea: purchased from Chongqing Tiangang Yuye Tea Industry Co., Ltd.

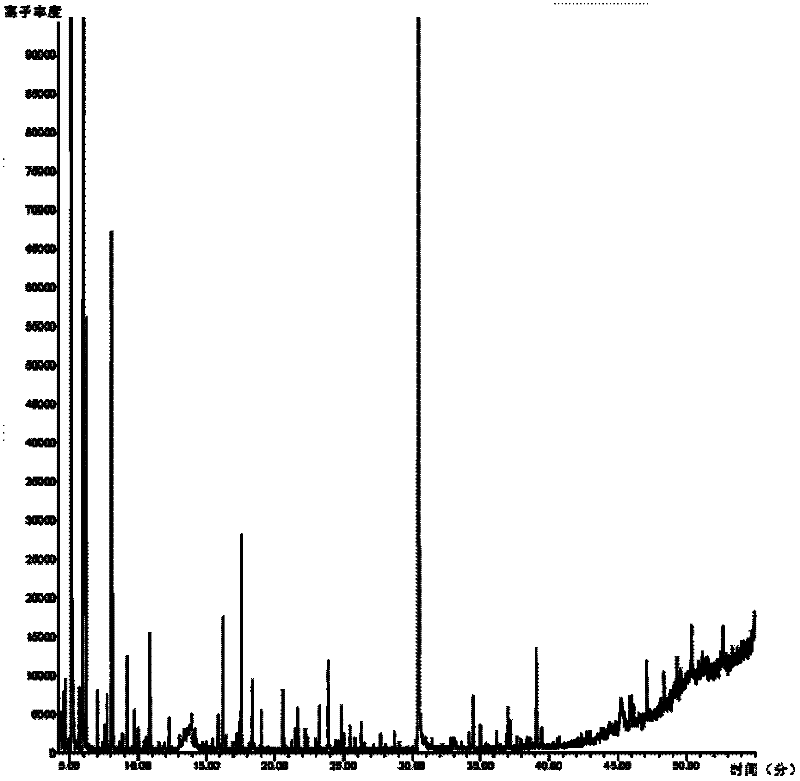

[0028] For green tea crushing, the charging requirement is 1kg / 100L supercritical CO 2 ; Supercritical CO 2 Extraction technical requirements: pressure is 20MPa, extraction temperature is 65°C, separation temperature is 70°C, extraction method: static extraction once, static extraction time is 60min. 4.5g of essence was extracted with an extraction rate of 0.45%. Through GC-MS analysis: the product is rich in more than 50 aroma components such as alcohols, ketones, aldehydes, ethers and esters, among which dimethyl sulfide, 2-methylbutyl The content of aldehyde and 1-penten-3-ol aroma components is higher, the results are as follows figure 1 and shown in Table 1.

[0029] GC-MS analysis conditions: Instruments: Agilent 7694 static headspace instrument, Agilent 6890-5973 gas chromatogra...

Embodiment 2

[0033] Embodiment 2 adopts the inventive method to extract essence from black tea

[0034] Black tea 20kg, source of black tea: purchased from Wukuaishi tea market in Chengdu.

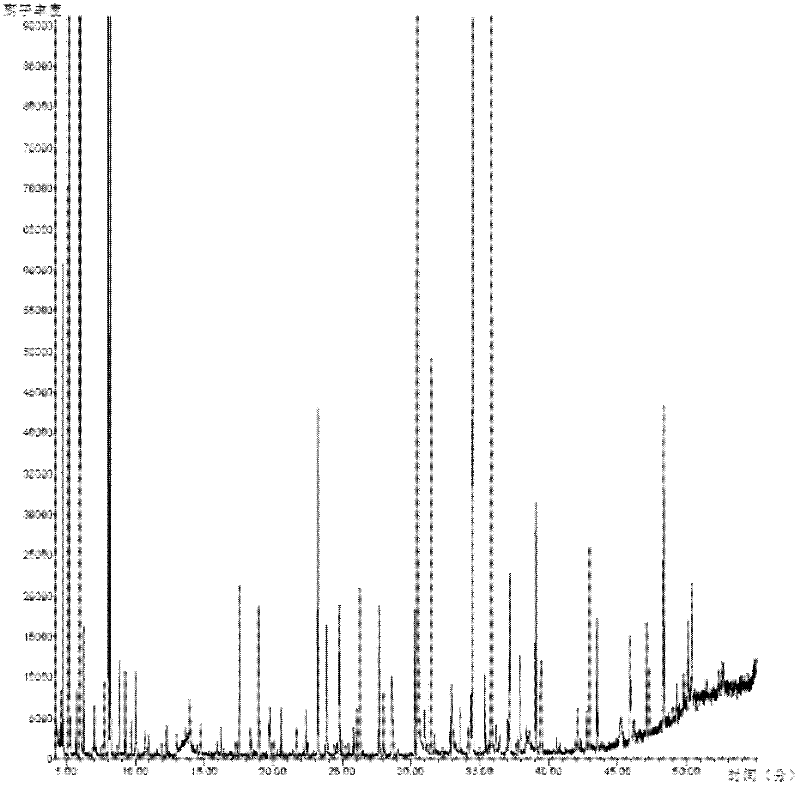

[0035] Black tea is crushed, and the charging requirement is 20kg / 100L supercritical CO 2 ; Supercritical CO 2Extraction technical requirements: pressure is 30MPa, extraction temperature is 45°C, separation temperature is 80°C, extraction method: static extraction 5 times, each static extraction time is 10min. 142g of essence was obtained by extraction, with an extraction rate of 0.71%. Through GC-MS analysis: the product is rich in more than 60 aroma components such as alcohols, ketones, aldehydes, ethers and esters, among which dimethyl sulfide, 2-methyl-propane The content of aldehydes, 2-methylbutyraldehyde and dehydrolinalool aroma components is higher, the results are as follows: figure 2 and shown in Table 2.

[0036] GC-MS analysis conditions: Instruments: Agilent 7694 static headspace ins...

Embodiment 3

[0039] Embodiment 3 adopts the inventive method to extract essence from oolong tea

[0040] Oolong tea 10kg, source of oolong tea: purchased from Wukuaishi tea market in Chengdu.

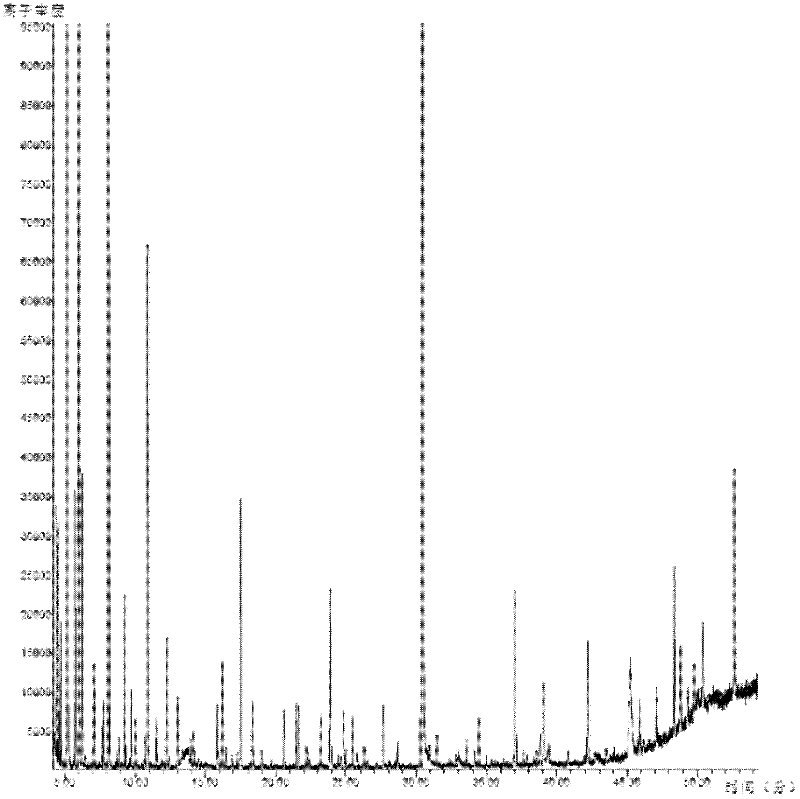

[0041] Oolong tea is crushed, and the charging requirement is 10kg / 100L supercritical CO 2 ; Supercritical CO 2 Extraction technical requirements: pressure is 50MPa, extraction temperature is 35°C, separation temperature is 75°C, extraction method: static extraction 3 times, each static extraction time is 40min. 63g of essence was extracted with an extraction rate of 0.63%. According to GC-MS analysis, the product was rich in more than 60 aroma components such as alcohols, ketones, aldehydes, ethers and esters, among which dimethyl sulfide, dimethylpropanal, The content of 2-methylbutanol and linalol aroma components is higher, and the results are as follows: image 3 and shown in Table 3.

[0042] GC-MS analysis conditions: Instruments: Agilent 7694 static headspace instrument, Agilent 6890-597...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com