Multi-disc type fine-pitch magnetorheological clutch

A magneto-rheological and clutch technology, applied in the direction of fluid clutches, clutches, mechanical equipment, etc., can solve the problems of small transmission torque, small structure volume, large transmission torque, etc., and achieve large transmission torque, high safety and reliability, and high transmission torque change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

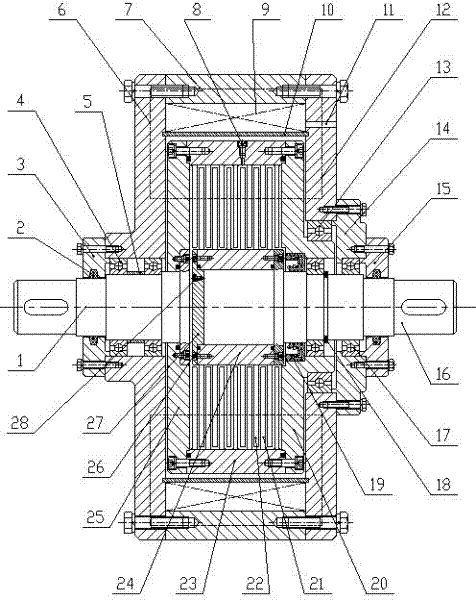

[0015] The present invention and an embodiment are further described below in conjunction with accompanying drawing:

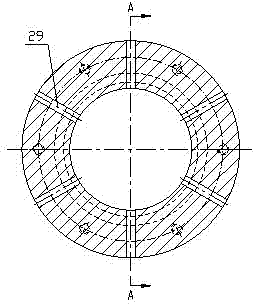

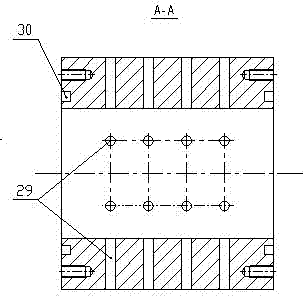

[0016] The multi-disk micro-pitch magneto-rheological clutch of the present invention is mainly composed of an input end part, an output end part, a magnetically conductive shell, and a supporting and sealing device. Wherein: the input end part comprises driving shaft 1, left and right baffle plates 25, 20, magnetic isolation sleeve 23 and driving disk 21, and driving disk 21 is installed in the magnetic isolation sleeve 23 by welding mode clearance, the radial setting of driving disk 21 There are multiple radial liquid return ports 31, and the number of radial liquid return ports 31 is 4 to 8, evenly distributed. During operation, the magnetorheological fluid can flow repeatedly between the main and driven discs 21 and 22, so as to accelerate the heat dissipation of the magnetorheological fluid and improve the stability of the magnetorheological fluid....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com